How to make a flute?

Many people want to learn to play some musical instrument. To make the process more fun, you can make some of the tools yourself. One of these will be the flute.

How to make paper?

A huge number of things can be made from paper: this is origami, and handicrafts useful in the household, and paintings, and even musical instruments. Children can be involved in making a flute, because such an activity contributes to the development of fine motor skills. So, in order to make a paper tool, you need:

- cardboard, preferably denser (you should not use thin paper, because the flute will turn out to be too soft);

- ruler;

- awl;

- PVA glue;

- gouache or any other paints.

You can create a flute with your own hands as follows.

- Using a ruler on a sheet of cardboard, the location of the holes of the future pipe is marked. The distance between the holes varies from 2.5 to 7.5 cm. The sound produced by the musician depends on this. For a paper flute, the minimum distance will work, excluding the thumb hole. Between it it is better to leave 4.5 cm. The account is kept from the bottom.

- Then the cardboard is rolled into a tube so that the marked holes remain on the front side. The product is glued with PVA.

- Next, holes are made with an awl, the uppermost of which should be slightly larger in diameter than the rest.

- Paints are used to give the instrument a beautiful appearance.

Of course, a paper flute will not sound like a real one, but this is a great way to spend time with children in an interesting and useful way.

PVC pipe flute

You can also make a pipe from PVC pipes. This will take more time and work, but the sound of the finished flute will be very close to the original.

Tools and materials

You will need the following items:

- PVC tube (it is better that the inner diameter is no more than 2 cm, and the length is 35-40 cm);

- PVC cap (suitable for the tool diameter);

- pencil;

- thread;

- file;

- saw;

- machine;

- vice;

- sandpaper of different sizes;

- primer for plastic;

- polyurethane-acrylic paints or electrical tape.

Manufacturing technology

Now let's look at detailed instructions for making a tool.

- Typically, water pipes are 100 cm long. Therefore, you must first saw off the excess in order to achieve the optimal size.

- To prevent the holes of the future flute from turning out to be curves, a thread is pulled from edge to edge of the pipe, which can be fixed with electrical tape.

- People who are versed in playing the flute can use their own schemes to mark holes. However, for beginners it is better to use the drawings offered on the Internet. The most common scheme is as follows: the diameter of the first hole from the top is 4 mm, the diameter of the next ones is 8-10 mm. Only eight holes. The first one from below is slightly deviated from the center towards the left or right hand. It all depends on which hand is leading. The musician blows into the first hole from above.

- Next, holes are drilled using the machine. In order not to damage the part from the inside, you can put a stick or a wooden block inside.

- After that, you need to put a cap on the flute from the side of the hole for sound extraction. This is to create pressure.

- Now it is necessary to sand the bumps and roughness in order to play the instrument. This will require sandpaper No. 4 and No. 1. First you need to go through a rough grinding, and then remove the small errors.

- Painting is the finishing touch. To create a smooth surface, the product is primed with a special PVC coating. After drying, polyurethane-acrylic paints are applied. You can make it even easier by pasting the resulting tool with multi-colored electrical tape.

The process of making a PVC pipe flute is quite time consuming. But you can really learn to play on it, and thanks to durable materials, such a product will last more than one year.

Other options

There are a variety of other options for making a flute at home.

Bamboo

Making a bamboo pipe is a tricky business. In addition to tools, neatness and patience are required. A mistake can lead to failure.

The following items will be required:

- bamboo stem (you can buy dried bamboo or dry it at home);

- metal rod with a diameter of 12-15 mm;

- gas burner (you can also make a fire, if possible);

- grip or durable canvas;

- saw for metal;

- felt-tip pen;

- sandpaper No. 2 or No. 1;

- old drill with a diameter of 4-6 mm;

- pliers;

- measuring tape;

- linseed oil and a rag.

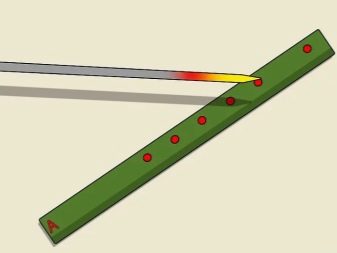

Manufacturing technology is as follows.

- Cut a piece of bamboo 40-50 cm long so that it is covered with a partition at one end.

- Make a mark at a distance of 20-25 mm from the end. Retreat 1.5 cm. Make more marks, retreating between them 20-25 mm.

- Heat the metal rod red hot to clean out unwanted fibers. It is imperative to use a grasp, otherwise burns cannot be avoided. After the rod is hot, it is inserted from the open side of the bamboo and pressed to remove the extra partitions. The section at the end must be left.

- The drill heats up. The marked holes are unscrewed by hand with a drill clamped in pliers. If you drill, the bamboo will crack.

- With the help of sandpaper, residues are removed after burning holes.

- The finished flute is covered with a layer of linseed oil.

Made of wood

Wood is an excellent material for making tools. Its feature is deep sounding. You can make a longitudinal pipe from wood. Unlike the transverse one, it has seven holes in the front and one in the back. Also, the two lower holes are often made bifurcated. For crafting, you will need two wooden blocks.The parameters are as follows: length - 30 cm, width - 2 cm, height - 1 cm.

Maple, pear and ebony sticks are suitable for the pipe.

Additional accessories:

- a small round piece of wood (the length of the part should be no more than 4 cm, and the diameter - 1.5 cm);

- ruler;

- pencil;

- semicircular incisor;

- clamps;

- vice;

- drill and drill from 0.6 to 4.5 mm;

- knife;

- sandpaper;

- PVA glue;

- file;

- tuner;

- wood stain or varnish for wood.

The work progress is as follows.

- Unlike bamboo, wood bars are not round in shape, so the inner groove of the pipe should be noted. From one edge, the width is 1.5-2 cm, from the other - 1-1.5 cm.

- Clamping a piece of wood in a vice, they begin to work with a chisel.

- After removing excess wood, both parts are sanded from the inside with sandpaper.

- At a distance of 4 cm from the wide edge of the workpiece, a 5x7 cm rectangle is marked. 3 identical holes are drilled with a 4.2 mm drill, which merge into one oval. With the help of a file, the oval turns into a rectangle. Then, on one side, the wood is grinded at an angle of 30-45 degrees. The flute whistle is ready.

- Then the parts are connected with PVA glue and left in the clamps for several hours.

- The dried workpiece is sealed with a round piece of wood.

- Using a knife, the part is cut and sanded. For convenience, a cut is made from the back of the pipe.

- The holes are marked as follows: the first goes 6 cm from the bottom edge, the rest - with an interval of 2 cm.

- The larger the hole, the higher the sound of the pipe, so tool setting and hole drilling are carried out in parallel. Tune the flute to open notes.

- At the end of the work, the pipe is varnished on wood. You can use both matte and glossy varnishes. The decor depends on personal preference.

Cocktail tube

This method is simple and does not require unbearable costs. The so-called Pan flute can be made from cocktail tubes.

What you need:

- cocktail tubes;

- Scotch;

- scissors;

- ruler.

The instruction is extremely simple.

- It takes 10 long tubes. Better to use bright ones. The tubes are shortened at the top. The scheme is simple: 2.5 cm is cut from the first tube, 2.5 + 2.5, that is, 5 cm, from the second, 5 + 2.5 (7.5 cm) from the third. All tubes are shortened in the same way.

- The tubes are folded in height and glued together with tape. The homemade tool is ready.

In order to acquire a flute, it is not necessary to visit a specialized store. It is enough to show ingenuity, patience and perseverance, and then it will turn out to make a tool that will really bring pleasure.

For information on how to make a flute out of wood with your own hands, see the next video.