All about sharpening the edges of alpine skis

Like skates or a snowboard, skis also dull over time - they have edges that should normally be sharp so that they can slide easily through the snow. Deformations of the sharpened corner edge lead to a deterioration in driving dynamics.

The need for sharpening

The corner cut, called the edging, allows the skier not to fly off when going downhill quickly to the side. The skier folds using the side of the surface.

Edges need good sharpening, regardless of the period of their use. The angle is sharpened sharply to prevent the athlete from slipping. This helps prevent injury. As you travel more and more distances, the angle loses its sharpness. The sharper the angle, the easier it is to brake when you reach the finish line.

In addition to distances, the hardness or looseness of the snow and pieces of ice that get in the way also affect the sharpness of the edge. The angle is periodically sharpened, but the service interval is different. For frequent and long driving, the edges are sharpened twice per winter on average, with rare episodes - once. You can not resharpen - the skis will fail much faster without having served the declared years.

Which canto cutter to choose?

Canto-cutters on the ski accessory market are pocket (amateur) and stationary (professional) models. For athletes who need to stay alert at all times, the pocket canto cutter is the right choice. But if skiing for you is not just a way to have a good time, skiing mostly on a gentle slope, but adrenaline and speed, then a multi-functional ski sharpener is for you.

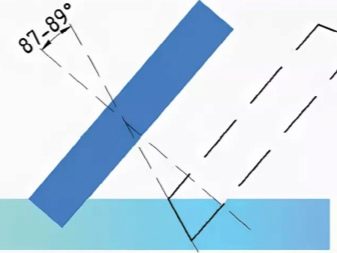

Before starting work, select the correct sharpening angle. The skis are sharpened from the side and sliding sides. Sliding surfaces must be grinded at an angle of no more than 1 °.Three degrees is too much: instability will increase sharply with certain riding styles. The slope on the sliding surface allows you to get rid of excess grip on the snow cover. The edge sharpening angle is the same along the entire length of the skis.

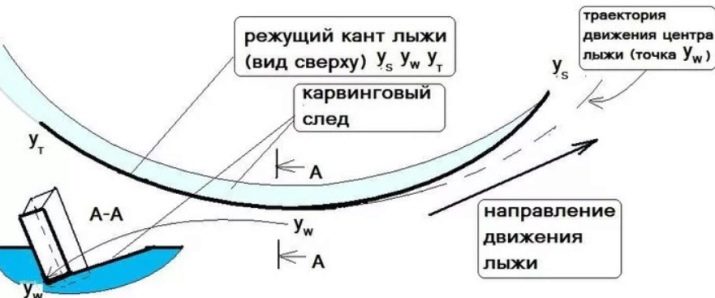

Sharpening of skis and snowboards is done with a flake file, which cuts off the factory waste. On the side, the edging is reduced by an angle of up to 5 °. If you are riding in the carving style, then on loose snow you need an edge angle of 89 ° (minus one from the right angle). To move on well-worn slopes, the edge is sewn by 2 ° (88 remains). An angle of 85 ° is made for driving on frozen and compacted snow, turning into a real one.

How to sharpen correctly?

Regardless of what is used - a machine, machine or other device - safety will always force you not to break the rules. Sharpening is done with protective gloves and goggles to protect the eyes, especially in the wind. The skis are clamped in a vice, additional sharpening is carried out with a file and / or an abrasive bar. The ski is placed vertically in a vice.

A file and a sharpening bar will remove any nicks and notches. The sliding surface is located on the other side of the work front. The canto cutter grinds more evenly - the optimal angle is set on it, and the sharpening is performed with movements along the entire length, and not chaotically.

Areas not in contact with snow should be rounded. The direction of movement is towards the back (tail) part, and not vice versa.

Blunt edges need straightening. They can be above or below the sliding edge, or this difference is uneven along the entire length.

- In the first case, the sliding edge is sunk into the snow deeper than the edges themselves. It is common for inventory to be stored incorrectly. To give such skis controllability, the sliding edge and edges are set to the same level. At home, this can be done using a rough sawn-off method, in a service center - by a finer grinding.

- The protruding edges press on the snow more than the main edge. Most often this happens when skis are not packed and stored in places with high humidity or significant temperature changes. They must be stored under a thin layer of special grease, which is applied to the edges and sliding edge. Protruding edges lead to the fact that the skier turns too quickly, there is no smoothness - he can abruptly leave the track. With your own hands, this drawback is corrected using a router with a stripping cutter.

The edges are sharpened until they line up with the sliding edge. The grain size of the cutter or bar is selected based on the specific situation. Grinding may be necessary after every ski run. When sewing edges, the side areas should not be covered with abrasive. Also, the sharpening should not slip when working.

To calibrate the skis, the side surface must also be processed. This is done with a file and an abrasive bar. If this is not done, perfect balance on the track will be impossible.

Maintain the optimum sharpening angle. It forms between the sliding side and the bottom of the sidecut. The correct angle is chosen depending on the condition of the track along which the athlete will ride. Carving skiing on hard snow requires an 87 ° residual angle. The piste of an average degree of ramming is 88 °, loose snow, which did not have time to be rammed, is 89 °.

If the descent is made at high speed from steep mountain slopes, then the sharpening becomes even sharper: about 85 °. If the skis are cross-country, then a flake file is needed, and the angle is set from 1 to 5 °. Roughly ground edges are polished with a diamond-plated disc.

In any case, the skis are placed on the machine or in a vice so that the sliding surface looks up. The nose of the skis is dulled to avoid traction.In all cases, precise grinding of the skis is indispensable: even, but roughly sharpened surfaces will cling to the track, despite lubrication and careful rolling of the slope.

For sharpening the edges of skis, see below.