All about the profession of process engineer

Each production cycle consists of a set of related technological processes, which are divided into basic, as well as supporting and developing. A key position in this chain is occupied by a process engineer, who is the main link responsible for the development and implementation of a new product. This specialist plays a huge role in any company., therefore, a person with the necessary knowledge and skills will never be left without a job and a decent level of payment.

Let us dwell in more detail on the description of the position of a process engineer and the requirements for applicants for this position.

Peculiarities

Translated from Latin, "engineer" means "discoverer" - that is, a person responsible for the implementation of options for improving a particular area of life. In other words, this is the person who makes inventions. Process engineer - an engineer who is responsible for the efficient organization of the technological and production process. Within the framework of this specialty, there are 3 main directions:

- inventive and scientific and practical activities;

- design work;

- introduction of scientific and technological progress into production.

The main goal that is set for an employee in the position of a process engineer and designer is reduced to the implementation of a competent choice of rational production methods.

Like any other profession, the job of a process engineer has its pros and cons. So, engineering technologies have such significant positive characteristics:

- demand for the profession;

- the ability to choose offers on the labor market;

- a high level of salary in the presence of the relevant competencies;

- possibility of career growth;

- weak competition.

At the same time, there are negative sides, they include:

- increased responsibility;

- high risk of injury while performing professional duties;

- contact with harmful production factors.

The position of a process engineer assumes the availability of fundamental knowledge in all areas and areas of the production process, as well as related disciplines.

This person should be engaged in continuous self-development, he should be distinguished by initiative, an active life position and the desire to constantly improve his skills, knowledge and competencies.

Responsibilities

In accordance with the professional standards specified in the ECTS, The job description of an employee in the position of a process engineer includes the following tasks.

- Compilation and implementation of a set of measures aimed at increased competitiveness of manufactured goods, reduction of material costs and labor costs at all stages of the production cycle.

- Creation and implementation of highly efficient technological processes, modern equipment, methods and solutions in terms of automation and mechanization.

- Adjustment operating modes of production cycles.

- Standardization of all processes in production.

- Calculation of economic efficiency production cycle.

- Expenditure planning necessary materials, fuel, and tools.

- Drawing up layouts of equipment in production workshops, providing jobs, monitoring equipment utilization and planning the use of production facilities.

- Determination of the sequence of the main work, development of a step-by-step production route.

- Formation of terms of reference for equipment, fixtures, and tools.

- Implementation of standards assembly of structures, technologies used, route maps, as well as other documents, one way or another related to the release of goods.

- Making adjustments in the technical documentation of production, if necessary.

- Participation in research and experienced research.

- Documentation approval with related divisions of the company.

- Implementation experimental research on the introduction of advanced technologies.

- Execution of functions by registration of applications for patents and prototypes.

- Development of a system of measures aimed at increase in labor productivity, introduction of advanced domestic and foreign experience in production.

- Formation of a set of works aimed at a more practical and effective development of existing production facilities and the improvement of the technologies used.

- Active participation in drafting management programs production equipment.

- Study the main reasons for the appearance of defects and poor quality of the manufactured product. Prompt development of measures for their further elimination and prevention.

- Control for the accuracy of meeting the requirements of industrial and labor discipline and the correct use of equipment.

- Consideration of the proposed rationalization proposals with the aim of improving the existing production technologies, making an expert assessment on the feasibility or inexpediency of their implementation.

Knowledge and skills

A competent process engineer must perfectly know:

- features of the manufacturing technology of the main product of the manufacturing enterprise;

- the exact composition of the raw materials used and the finished product, the design features of the products;

- the main methods and options for the design of existing technical and technological processes;

- laws, regulations, orders, as well as some other regulatory and methodological documents related to production processes;

- design and composition of equipment, requirements for its maintenance, basic mechanisms of their operation and permissible operating modes;

- technical and technological work standard;

- basic standards for the quality of raw materials used and manufactured goods;

- established GOSTs, standards and norms;

- economic indicators of production technology;

- permissible indicators of marriage, methods of its prevention and methods of elimination;

- principles of labor organization in production;

- basic means of working communication and features of the use of IT in the production area;

- approved requirements for processing technological and reporting documents;

- basic postulates of economics and ergonomics;

- knowledge of the Labor Code of the Russian Federation;

- existing standards of safety and industrial sanitation, as well as fire protection rules and legislation in the field of labor protection;

- rules of business communication with subordinates, colleagues and partners;

- knowledge of computer programs.

A process engineer is a highly qualified employee, he must be well versed in the intricacies of the production cycle.

It is this specialist who is responsible for the quality of the products, the continuity of technological processes and their speed.

That is why, in addition to deep technical knowledge, this employee must have good management skills, since the efficiency of all production as a whole directly depends on the organization of the effective work of the entire labor collective.

The position of a process engineer presupposes not just a set of narrowly professional specialized skills and abilities, but also a certain list of personal qualities. There are at least a dozen workers in the subordination of this employee, so his ability to build communication and rationally manage labor resources largely depends on the efficiency of production as a whole.

Important personal qualities for a candidate for the position of a process engineer are:

- organizational skills;

- high level of self-discipline;

- attention to details;

- scrupulousness when working with diagrams and drawings;

- perseverance;

- self-organization;

- perseverance, perseverance and dedication;

- analytical and abstract thinking;

- high learning rate;

- striving to constantly improve their skills and knowledge;

- the ability to memorize a large amount of data;

- poise and restraint;

- sociability;

- hard work;

- punctuality.

In general, this list may vary, it largely depends on the industry of the company in which the process engineer will work. As a rule, each manager has his own requirements for the personal qualities of the employee.

Education

A number of specializations are hidden under the general concept of a process engineer; they depend on the characteristics of the production and technical orientation of a particular company. Regardless of the existing varieties of this profession, in any case, in order to take the position of a senior technologist, you should get a higher technical or secondary education in a technical profile. Secondary specialized education is usually obtained at the end of the 9th grade at school, who studied at the school / technical school for 3-4 years. In order to become the owners of the "HSE", you must complete 11 classes of school, and then study for 4 years for a bachelor's degree and another 2 years for a master's degree.

The passing score in these areas may vary depending on the region where the educational institution is located, as well as its level of prestige. Training can be free or carried out on a commercial basis, the cost in Russia is 20-110 thousand rubles. in year. For admission, you need to pass items such as mathematics, physics and computer science.

Preference is given to graduates of full-time study programs, distance education is allowed only with extensive experience in the chosen specialty.

In our country, there are about 110 universities and over 200 educational specializations, which allow graduates of an educational institution to apply for the position of a process engineer.

average salary

The salary level of a process engineer largely depends on the specifics of the enterprise where he works, as well as the region. If we take the generalized indicators based on the data sent by labor exchanges, on average in the Russian Federation, the payment of a process engineer is:

- minimum wage - 25 thousand rubles;

- average wages - 50 thousand rubles;

- the highest level of payment - up to 450-550 thousand rubles.

This figure is average, it can vary depending on the nature of the position held.

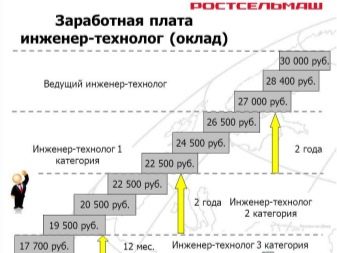

So, the average salary for the position:

- chief technologist - amount to 66-70 thousand rubles;

- leading process engineer or the head of the technical and technological department receives about 55-60 thousand rubles;

- ordinary engineer-technologist earns 40 thousand rubles.

If we talk about the average salary in the regions of the Russian Federation, then the picture with the average salary will look like this:

- Moscow - 75 thousand rubles;

- Vladivostok - 60 thousand rubles;

- Yekaterinburg - 48-50 thousand rubles;

- Rostov-on-Don - 40 thousand rubles;

- Kazan - 40 thousand rubles.

Where to work?

The list of production areas that require the mandatory presence of a process engineer on the staff is quite impressive. Depending on the chosen specialization at the training stage, an employee with the necessary set of competencies and skills can be employed in the following industries.

- Food - confectionery and bakery industry, production of dairy and lactic acid products, meat processing enterprises, public catering system.

- Light - fur, sewing and textile production.

- Chemical - shops for the production of medicines, cosmetics, as well as building materials, concrete, etc.

- Mechanical engineering and instrument making - electroplating shops, locomotive facilities, CNC, manufacturing of welding equipment, power plants, oil and gas production and petrochemistry, as well as plants and factories in the segment of technological equipment servicing.

- Metallurgy and metalworking - production of steel and alloys, heat treatment of ore, coke and gas factories, mining and processing companies.

- Oil refining - production for the extraction and processing of oil, the manufacture of fuels and lubricants, drilling fluids, the manufacture of petrochemical products, enterprises for the provision of oil and gas production.

- Information Technology.

- Printing industry.

Career

The position of a process engineer is usually assigned to a person who has a higher specialized technical education without specifying any requirements for work experience, or a person with secondary specialized education, whose work experience in the position of a process technician is at least 3 years. Thus, a person with no work experience can qualify for career growth following the scheme.

- Category III specialist - an employee with a higher technical education, as well as a short experience acquired during training, or having experience in engineering positions without any qualifications.

- Category II specialist - an employee with a higher education, and in addition, work experience in the position of a process engineer of the III category or snow technical positions for a period of at least 3 years.

- Category I specialist - an engineer with a higher profile education, as well as at least 3 years of experience in the position of an engineer-technologist of the II category.