Types and selection of rods for glue guns

The ability to create something with your own hands has always attracted creative people, so it is not surprising that the industry is actively developing in this direction. More and more tools and raw materials appear on the shelves every day, with the help of which you can draw, sew, create any crafts and products. One of the most convenient and versatile devices has become a glue gun, thanks to which it is possible to glue any surfaces much faster. To use this device correctly, it is important to select the right rods for it.

What it is?

Using PVA glue, super glue and similar options is not always convenient, and the result may not correspond to the desired one. Therefore, a hot melt adhesive was created, which, when exposed to temperature, becomes liquid, lays well on the surface, and after a couple of minutes freezes, grasping tightly. A distinctive feature of glue sticks is that the melted components can fill holes, pores, cracks and folds in the surface for better adhesion.

These products can be found under the following names:

-

glue sticks;

-

thermoplastic or hot glue;

-

cartridges for a thermal gun.

Due to its properties, the molten composition can be applied to paper, cardboard, wood, glass, plastic, leather, ceramic, stone and other surfaces.

The advantages of this glue include:

-

adhesion strength;

-

drying speed;

-

duration of service;

-

the ability to remove glue without marks on the surface;

-

use as a sealant;

-

the ability to glue different surfaces;

-

lack of harmful components in the composition;

-

adequate cost;

-

long-term storage.

Glue sticks have several disadvantages:

-

weak plasticity and rather rigid adhesion;

-

limited use for some surfaces - certain fabrics, PVC, plaster, concrete.

The purpose of the hot melt glue is the same as for other varieties, the method of its use will be different. Knowing how to choose and use the right adhesive, you can successfully join a variety of surfaces for the necessary purposes.

Melting temperature

The composition of glue sticks can vary significantly, which affects their melting point. Products based on EVA melt already at + 80 ° C, and the operating temperature is considered to be in the range of + 120 ... 150 ° C. Use of such rods is recommended for the household type of glue gun.

The rods, consisting of polyamides and polyolefins, begin to soften at + 155 ° C, and the operating temperature for this variety is considered to be + 180 ... 200 ° C. Such rods are already used in professional equipment capable of withstanding heating up to + 500 ° C. To glue surfaces that can withstand heating to high temperatures, high-temperature compounds are used.

The choice of rods must be made based on the type of surfaces to be worked with and the equipment that is planned to be used in the process.

What are they?

Heat gun rods can be of different compositions, colors, thicknesses and melting points. To know which species are worth using in a particular case, you need to know the characteristics of all varieties.

Not understanding how one option differs from another, you can ruin the work surface, and waste time and money in vain.

By composition

Glue sticks are made from polymer, plasticizers and resins. The composition of the polymer can be different, hence the types of adhesive products.

-

EVA (ethylene vinyl acetate) - the melting point is low, have high adhesion, the degree of bond strength is below average. Cured glue does not break down in contact with water and other substances.

-

Polyamide - have a high melting point, are more rigid, create a strong seam. Having constant contact with moisture, the glue loses its properties.

-

Polyester - have good resistance to any factor in the atmospheric environment. They have high adhesion. This glue can be used for gluing any surfaces.

-

Polyolefin - have the highest density, are difficult to melt. The resulting seam is hard and has low adhesion.

-

Silicone varieties - melts at low temperatures, the resulting seam is transparent and plastic, resistant to stress.

-

Synthetic rubber rods - have high elasticity, they tolerate contact with moisture well.

-

Polyurethane - creates the most durable and elastic seam that is resistant to high and low temperatures. A feature of this variety is the hardening period, which lasts up to 48 hours.

Depending on what the glue stick consists of, its melting point, strength and color of the resulting seam change.

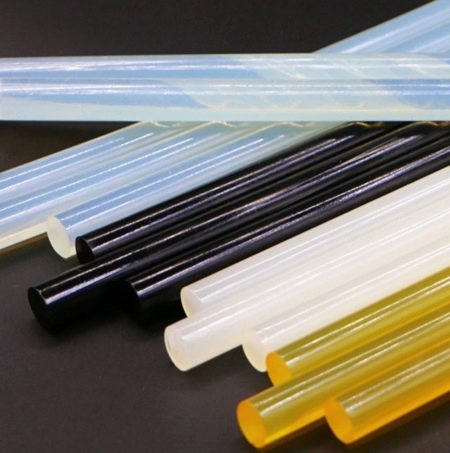

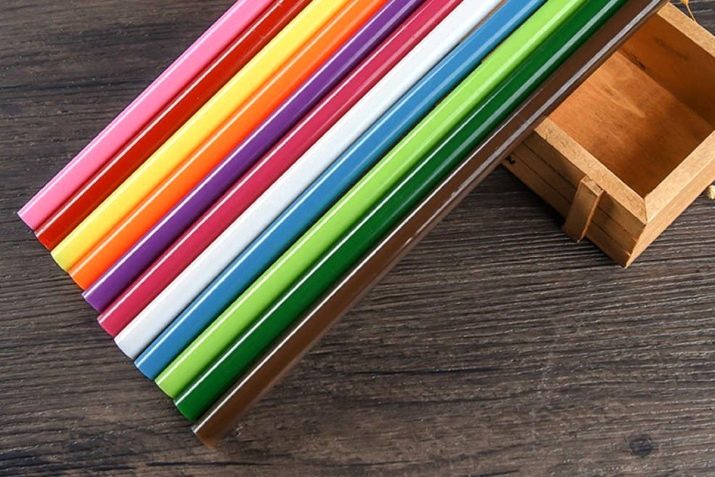

By color

To make it easier to select the desired glue stick, manufacturers began to use color separation of goods.

Knowing the characteristics of each color, you can easily choose a hot glue for a specific heat gun.

There are several color varieties.

- Colorless - the most popular option, which is used for gluing most surfaces. The resulting seam is characterized by softness, ductility and high adhesion.

- Transparent (yellow) - rods, used for paper, cardboard, wood. In some cases, they can glue plastics and metal. Such glue has a weak adhesion and absorbs moisture, therefore it is not suitable for strong fixation.

- White - can be used for joining glass and metal surfaces, suitable for wood, plastic and textiles.

- Multicolored - colored varieties are created on the basis of EVA, a feature is the ability to match the color of the seam to the shade of the surface that will be glued to make the glue as invisible as possible.

-

Black - a universal option that can be used to replace sealants or as a joint sealant between elements, it can insulate electrical contacts.

Thinking over the work of gluing different surfaces, it is necessary to take into account the peculiarities of the glue, choosing the color of the rods that will create a reliable seam and make the process quick and comfortable.

To size

Depending on the pistol, the size of the rods is also selected. The diameter of the product can be different, but the most popular is 11 mm. This hot melt glue is suitable for most of the inexpensive simple and light guns. Due to the optimal thickness, the equipment with low power cope with the melting of such rods. For any household needs, for minor repairs or temporary fixing of any elements, one cannot do without the use of rods with a diameter of 11 mm.

In needlework, it is worth using rods with a diameter of 7-8 mm, they are convenient for delicate work and allow you to make neat seams on any surface.

If professional equipment is used, then the content for it should be completely different. The optimal rods for such pistols will be products with a diameter of 12, 15 and 43 mm.

The length of the hot-melt adhesives can also vary. For small jobs, rods with a length of 4 cm or more are suitable. The most demanded for creativity and household needs are products 10-20 cm in length. For long-term and professional use, adhesives with a length of 30 cm may be required.

Nuances of choice

To choose the right rod for a hot air gun, you need to know the basic parameters of the products that can be used in it. Not knowing the correct size of the rods, it is worth starting with standard products 11 mm thick and short in length, so as not to spend extra money if the choice was not made correctly.

It is necessary to select rods according to their composition, depending on the type of surface with which to work, and the operating conditions of the finished product. Color will help you quickly find the type of product you want to get the desired effect. If there are no special requirements for the color of the seam, then you can buy an opaque version, if the glue should merge as much as possible with the shade of the surface on which it is applied, then it is better to choose a color variety of a suitable tonality.

White and black glue can be used on most surfaces.

Having dealt with the peculiarities of the varieties of glue rods, you can ensure yourself easy and comfortable work with them and get a high-quality and reliable seam that will last as long as possible.

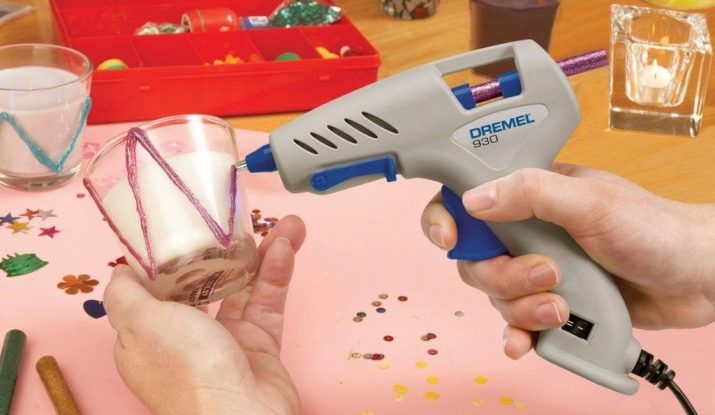

How to insert and remove?

There is a simple instruction to load a stick into a glue gun. To do this, plug the device into a power outlet and wait a couple of minutes for it to warm up. On the side of the handle there is a hole where you need to insert hot melt glue. By pressing the button of the gun, the glue mass is pushed out through the spout of the device. As soon as the rod ends, you need to immediately place another behind it, otherwise there will be nothing to push the glue out of the gun.

If you need to change the glue stick or remove the old one, you need to turn on the gun, wait 2-3 minutes and pull the glue mass towards you. If the product does not come out, you need to let the equipment warm up still, then try again to remove the rod.

After working with a thermo-gun, it is important to clean the spout of the device from glue residues each time, otherwise the process of gluing the surfaces will become difficult.