Everything you need to know about skate blades

The skate blade is the most important element of this sports equipment. It has a huge impact on the quality of skating, the performance of various tricks on ice. These products can be of various types. In the article we will talk about the features of such blades, their varieties.

Primary requirements

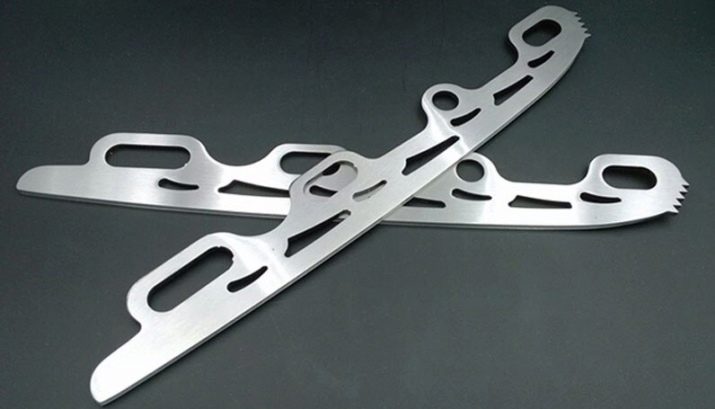

Skate blades must be made of high quality processed metals (various types of steel). Such products can easily withstand significant loads, while they will not deform.

The surface of these parts should be completely shiny, glossy. Even small matte stains are not allowed on it. An exception can only be samples with special protective coatings, due to which they acquire a matte finish.

Besides, these elements must be made as stable as possible so that during the skating process the user can confidently stand on skates and perform various movements and tricks.

Views

There are a wide variety of different skate blades available today. Let's consider some classifications separately. Depending on the material from which they are made, there are several types.

- Stainless steel models. Such steel contains chromium, which is able to increase the resistance of the base to the formation of corrosion.

- Alloy steel models. This blade metal contains various additives that give it maximum strength and hardness.

- Carbon steel products. This material contains a small amount of carbon. The higher its content, the harder the part will turn out.

Depending on the type of design, there are monolithic and removable blades. The difference is that the second option can be easily removed at any time. Detachable varieties are considered the most preferable, since in case of breakdowns the blade can be replaced with a new one without buying new skates.

These products for skates can also differ in their purpose: models for figured, walking, hockey boots.

Popular manufacturers

It is worth highlighting some of the most famous companies that specialize in the production and sale of blades for various types of skates.

-

John Wilson. This company from Great Britain is considered the oldest manufacturer of such products, it was founded in the 17th century. The brand currently produces curved blades that are created from high quality processed steel. The brand's products most often have a special system of teeth with a criss-crossing design. This allows you to increase the working area. All models provide excellent grip on icy surfaces.

-

Jackson Ultima. This Canadian brand produces blade lines for simple figure skates as well as professional athletic shoes. The company's products, as a rule, have a classic design. The blades are crafted from a machined, durable steel base. They are available in a wide variety of sizes. Jackson Ultima products sometimes come in a double-edged design that includes the blade itself and a special platform that attaches to the sole of the athletic shoe.

-

Ramonedge. The brand produces high-quality ice skate blades, including models designed for hockey skates. These products are sold with special certifications, which indicate all the information about the part. Ramonedge blades are manufactured from a special alloy and a unique profile that has been specially designed for these designs. The surface of the products has a special coating, which prolongs their service life and performs a protective function.

-

Graf. This company specializes in making a wide variety of blades, including those used for professional hockey skates. Brand products can be produced in various sizes. The platform of these blades is made of special lightweight plastic, which has a fairly high level of strength. In addition, the material is absolutely frost-resistant, it will not deform even when used at low temperatures. Most often, the brand produces removable models, which, if necessary, can be easily changed to others.

These blades provide maximum maneuverability when moving on ice.

-

Bauer. This manufacturer specializes in the manufacture of stainless steel blades. At the same time, the range includes models for both professional hockey and simple walking skates. Many models are designed for heavy loads.

- CCM. This brand is a major manufacturer of various hockey equipment, including skate blades. Models produced by the brand are treated with a special protective coating, which significantly extends the service life of the product. The company manufactures skate blades in various sizes.

Criterias of choice

When choosing the right model for your skates, you need to consider a number of important features. Be sure to look at the shape of the product. So, hockey-type blades look like a small groove with two sharp sharpened edges. In addition, models can have a larger or smaller radius of curvature, and the level of bend, in turn, is directly proportional to the level of maneuverability and balance.

It is also necessary to look at the dimensions of the blade. These parameters include thickness, length and width, height.In order for the skates to fit in size, you should purchase all products from the same manufacturer. All values are indicated on the product labeling. Children are usually smaller in size. Remember that the optimum blade thickness for solo skating should be no more than 4mm. If you are looking for a model for dancing shoes, then it can vary within 3 mm.

When determining the optimal width, the approximate weight load and the type of athletic shoe itself should be taken into account. The standard is considered a value of 2.65 centimeters, but there are also narrower and wider varieties.

And also before purchasing, you should immediately determine from what material the blade is made. The best option would be varieties made of stainless steel. They are particularly durable and reliable. In addition, such samples will not be negatively affected by moisture.

Nowadays, models made of special aluminum alloys, which have optimal strength, are gaining more and more popularity.

It is recommended to choose a blade that will be treated with a protective compound. Such models can last as long as possible. Most often, after coating, the products acquire a matte surface.

When choosing such products, it is worth considering the design of the part. It is better to take a removable model, as it will be possible to replace it yourself in the event of a breakdown. Before buying a suitable copy, you should carefully examine its surface. It should not even have minor scratches, chips and other similar defects.

Replacement

The blade on skates can be replaced by yourself. To properly fit this piece, you will first need to place the palm of one hand on the lacing in the middle of the shoe. With this palm, you firmly grip the skates, and with the other hand you need to remove the old blade.

The back of the skates is placed on a table or other flat surface, after which the hand is grabbed by the toe of the boot. Carefully insert a flat-head screwdriver into the groove of the first screw and hold it in this position. Then, using pliers, grasp the fastener on the other side of the first screw.

Next, turn the screwdriver counterclockwise until it begins to weaken. Later, the screw is unscrewed from the plastic holder. A screwdriver is inserted into the fastener and a little force is applied to remove the fastener.

After that, the shoes are again placed on the table. The same flat head screwdriver is fixed in the groove of the second screw element, and held in this place. Next, take the fasteners with pliers, and begin to turn the screwdriver until the latch starts to wobble. He is also pulled out.

When the screw parts are unscrewed, it is worth wrapping your hands in advance with a cloth towel. Only then you need to clamp two flat sides of the blade at once between the index and thumb. Do not touch the edges of the product and the lower section, so as not to injure yourself.

Then fingers are applied to the side of the blade and gradually pull it up. In order not to injure your hands, the part should not be lifted too quickly in one motion. After removing the old element, a new blade can be installed. It is fixed with special rivets. If you do not want to do such a replacement yourself, then you can take the skates to the workshop.

For information on how to sharpen skates correctly, see the next video.