Chipboard countertops for the kitchen: types and choices

Chipboard countertops today can no longer be considered the most in demand, and yet they have a certain number of fans. At least many manufacturers still do not refuse to release products from a material that is so often criticized by certain segments of the population. This means that some demand remains, therefore, it is worth getting to know the chipboard countertops better.

Advantages and disadvantages

A couple of decades ago, a chipboard kitchen countertop was a mass phenomenon, but today it has been largely replaced by more modern materials. The fact that particle board has not completely disappeared until now, indicates the presence of certain advantages of its use, which should be considered more carefully.

- Low cost. We can safely say that this is the main selection criterion, since there are simply no other cheaper alternatives.

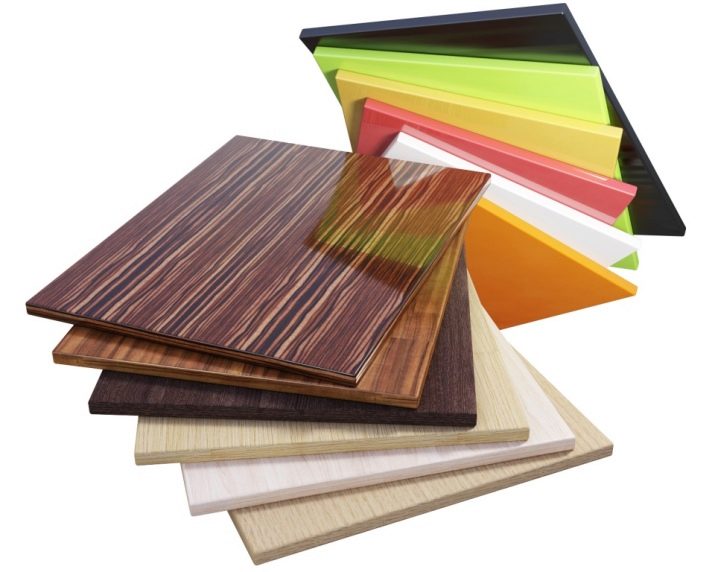

- Variety of colors and textures. Chipboard kitchen countertops can look completely different, since the material involves simple processing, it can be painted and even contain a complex print.

- Resistant to fading. The pigment that gives color to a single-colored plate can be incorporated into the composition of the substance even at the manufacturing stage, therefore, ultraviolet rays are not terrible for the product.

- Appropriateness in the kitchen. Let's make a reservation right away that all these advantages are relative, however, the chipboard countertop is capable of withstanding high temperatures and mechanical stress, and it is also practically indifferent to the activity of food acids.

- Laminated coating. In most cases, in the kitchen, a laminated version of the plate is used, which has no pores, and therefore does not lend itself to destruction by moisture and does not absorb dirt.

Despite all the above qualities, the indisputable fact is that most of the alternative materials are superior to chipboard in terms of basic characteristics, which is why chipboard lost its primacy to competitors. The obvious disadvantages include a number of chipboard features.

- Formaldehyde in the composition. In recent decades, humanity has become increasingly attentive to toxins, at least in their own homes. Particleboard contains a lot of extraneous "chemicals" that can be released into the air. Manufacturers claim that they have reduced the amount of toxic glue and resins in the composition, and lamination on all sides prevents secretions, but you yourself must understand that the risk does not go away.

- Swelling with moisture. If water finds a way to get through the laminate layer to the chipboard core, it will certainly cause the latter to swell. The consequences will be deformation and loss of attractive appearance or even ease of use of the table.

- Doubtful reliability of the laminate. The two above-mentioned points show that without solid chipboard lamination, the material is rather dubious. In the meantime, it is quite easy to damage the laminate with a knife, alkalis or concentrated acids.

What is postforming?

Considering the aforementioned questionable qualities of the board, which it has in an unprotected form, the production of countertops usually directly assumes that the finished product will have some kind of "wrapper" as an outer layer that protects too fragile and potentially dangerous pressed chips. At the same time, most conscientious manufacturers prefer to optimize the operation of the slab through a method called postforming.

Its essence lies in the fact that plastic lamination takes place at high temperatures and with the participation of a special press... The layer of plastic coating acquires smooth curves, so that the finished countertop will not have sharp corners or cuts - it will become smooth and sloping on all sides. This shape significantly minimizes the risk of injury, and also contributes to additional protection of the core from moisture penetration.

There are two main types of post-formed slabs. The simplest is called L-type, in this case, plastic covers the chipboard on one side and on the end. The so-called U-type is even more effective, when the plastic layer "hugs" the countertop from both sides.

Types of coatings

Laminated chipboards are covered with different materials for additional protection from negative external influences and to improve the appearance from the outside, which are called by the general term "laminate" for convenience only. The protected sheet is briefly called laminated chipboard. Its specific characteristics depend on which version of the laminate was used.

Most often, four main materials are used, each of which should be considered separately.

- Melamine foil. In fact, this is craft paper, which is impregnated with a special melamine resin for greater reliability. The thickness of the protective layer is even slightly less than half a millimeter, but such a coating can have the most unexpected colors and patterns, and therefore is in great demand.

- Plastic. One of the most popular laminate flooring options, which, at a relatively low price, provides sufficient chipboard protection parameters. There are two types of plastic coating - high pressure sheet and continuous pressure roll. By most criteria, both options are identical to each other, but differ mainly in thickness - the second is much thinner than the first (0.15-1.5 mm versus 0.5-6 mm).

- Veneer. This kind of lamination could be very valuable if it was as practical as it is beautiful.On top of the chipboard, veneer is laid out, everything is varnished on top, so that the finished tabletop looks like a natural solid wood and looks just amazing. At the same time, the product does not differ in moisture resistance at all, and it is also very easy to scratch it, therefore in kitchens such a finishing option is not often found.

- Stainless steel. Perhaps it is not entirely correct to call such a material a laminate, and yet it can be sheathed with chipboard countertops. With the right approach to the design, it can look quite beautiful, in addition, it is also very practical, but such a solution will cost the customer a lot, because the option is usually appropriate only in public institutions.

Dimensions (edit)

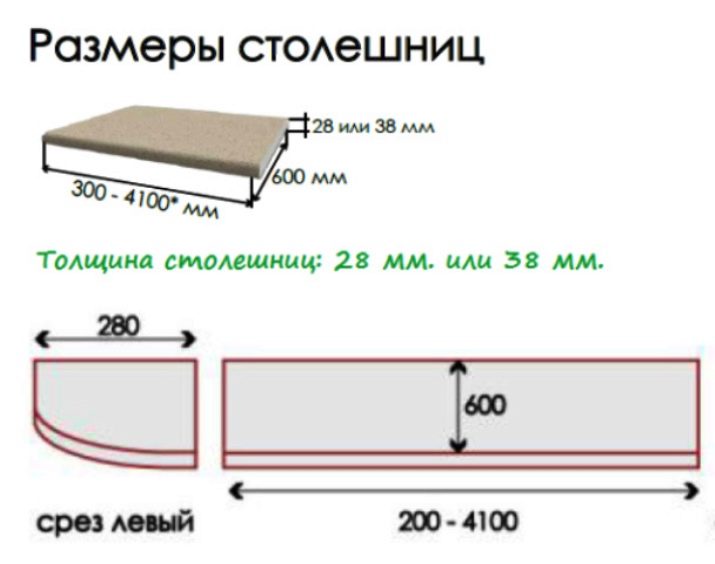

Countertops made of any material are either ready-made, produced by the manufacturer in standard dimensions and sold in a building hypermarket, or individual ones - they are made to order, and therefore can have any shape and size. A separate production of a single copy, of course, is more expensive, and since chipboard is often chosen precisely because of its cheapness, it is clear that individual orders from this material are rare.

The thickness of the countertop is one of the most important characteristics, since for a relatively fragile material (in comparison with the same stainless steel, MDF or ceramics), it gives a certain margin of safety. The 28 and 60 mm standards are quite common, but 38 mm is considered the most popular.

In principle, if any outstanding loads are not expected, you can use a slab of any thickness from those available in the nearest store.

The width of the chipboard worktop is even more variable - the slab can be either 400 mm wide or 1200 mm wide. Postforming inevitably adds a centimeter or two to the length of the countertop, therefore it is necessary to clarify whether its protrusion is included in the declared indicator or not. It is necessary to choose the width of the product so that the owners can easily reach the far edge of the countertop located against the wall, and therefore most often they choose models with a width of 600 mm.

The advantage of chipboard worktops is also the fact that the range includes models of different lengths - from 2450 to 4100 mm. This is especially important given the fact that trimming the product is undesirable - this will break the protective contour of the laminate.

Thanks to the variety of sizes, you can choose the stove that will most accurately fit into the dimensions of your kitchen.

Color solutions

A feature of chipboard is that during the production process, pigment of any color can be mixed into the pressed shavings, so that the finished product does not even have to be painted - it will already have a certain shade at the exit from the conveyor. Most often, in production, they are guided by the most popular colors, which include black, white and shades of wood. The advantage of this color is that it does not fade.

If necessary, chipboard, like any other material, can be painted on the outside, including by applying a print or drawing to its surface. In this case, it is usually necessary to decorate not so much the chipboard itself as the outer layer of plastic or other laminate. Manufacturers usually do not offer intricate design options, the height of complexity for them is some kind of pattern.

Wanting to put something more original on the stove, the consumer will have to order an individual release of the model.

How to choose?

Regardless of whether you need a tabletop for a table or as a cover for a kitchen set, the first thing you should pay attention to is dimensions... The length and width of the product are determined not so much by your own wishes, but by the dimensions of the kitchen, which usually puts its owner in a tight framework.

As for thickness, then it is usually chosen in an arbitrary way, unless you are trying to imitate something. For example, Chipboard, similar in design to natural stone, simply cannot be too thin - from this it will seem implausible and ruin the interior.

It is important to choose the right registration countertops, so that it is competently combined with both the color scheme of the room and the style of its decoration.

If chipboard imitates another material, then it should be appropriate: "metal" will fit better into a high-tech kitchen, and "wood" goes well with ethnic design.

It is also worth thinking about how the countertop will be used. In many cases, housewives are engaged in cutting products directly on it, and so that the resulting scratches and other mechanical damage are not conspicuous, a matte plate with a variegated color should be preferred, which will hide the defects that have appeared.

Finally, it is important that the chipboard itself is of the highest quality... Pay attention to the detailed characteristics indicating the degree of water resistance and the emission class, but if there is no such information at all, this is already a hint that the product is made just like.

Among other things, also make sure that your copy is new and not damaged during the shipping process.

Operation and care

Particleboard is very afraid of water, because it is important to monitor the integrity of the lamination layer, especially in those places where the worktop is adjacent to the sink and hob. If a leak is found, the panel should be repaired as soon as possible using a special sealant.

It is unacceptable to put any hot dishes on the chipboard worktop without using a thermal insulating stand. - with this you will most likely "kill" the panel. Although the chip filler itself is not afraid of high temperatures, the latter can melt the plastic protective layer, and this will not only be ugly, but also dangerous due to the risk of moisture penetration. By the way, you can't put frozen food on it either - the cold provokes the flaking of the plastic.

It is not recommended to cut food on plastic-coated countertops, otherwise the surface may be damaged.

For chipboard countertops for the kitchen, see the next video.