How to make a do-it-yourself end cutting board?

A cutting board is a kitchen tool used for various types of food processing. It allows you to manually cut, chop and grind food.

Features and varieties

Their main feature is the presence of a flat, even surface, due to which it can be used with greater efficiency.

The materials from which the cutting boards are made are plastic or various types of wood. Wooden models are considered the most acceptable for everyday use. This is due to the fact that during operation the cutting tool exerts a mechanical effect on the board, which leads to microscopic damage. As a result of these damages, the surface is destroyed, and small particles of the material from which it is made fall on the products.

Cutting planes differ from each other in shape, name of material and purpose.

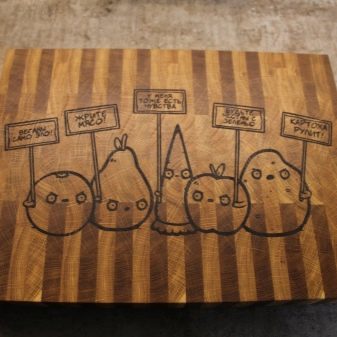

The shape of the board can influence the way it is used. For example, the surface of one of its sides can be finished with a decorative pattern or pattern, which makes it impossible to use this side.

The woody material used to make a cutting board may differ depending on its intended use. Due to its properties in the manufacture of boards, the preferred choice is given to it. There are wood species that are distinguished by high parameters of strength and resistance to destructive loads. Among the most popular types of wood used in this case are:

- oak;

- beech;

- nut;

- ash;

- maple.

Cutting planes made of wood are divided into two types: ordinary and end. Their main difference from each other is the position of the wood fiber relative to the cutting surface and the position of the cutting tool. In the first case, the fiber is positioned horizontally, parallel to the surface on which it is installed. In the second case, the fiber direction is vertical.

Advantages of an end board

A board of this type has a number of features that give it specific advantages that determine the area of use. Since the fiber is vertical, its position relative to the cutting tool blade is perpendicular.

This fact determines the presence of increased strength. This is due to the fact that the end part of the wood fiber is much stronger than its longitudinal part. So, when sawing wood material, it is much easier to saw the workpiece across the fiber than along it.

Using this feature, craftsmen make durable cutting boards. These kitchen items are in demand in high-volume food environments such as restaurants and canteens.

Due to the advantages of vertical fiber boards, the percentage of money and other resource costs allocated to providing public kitchens with specialized utensils is reduced.

End Plank Manufacturing Principle

Time-tested technologies are used in the production of end boards to achieve the desired effect. It is known that a flat saw cut from a tree, the grain of which is directed perpendicular to the surface on which it is laid, can be extremely fragile. To compensate for this disadvantage, the cutting board is made of components glued together, the fiber of which has a different direction relative to each other. To fasten the components to each other, it is necessary to select an adhesive whose properties could ensure the proper connection of the workpieces. The strength of the joints between the workpieces must be sufficient to maintain the integrity of the board under loads.

Since a cutting board is a household item that comes in contact with food, you should only use specialized glue. Its packaging must indicate permission to use for gluing materials that will be in direct contact with food. This will prevent harmful glue particles from entering the human body, which will consume food prepared on this board.

It is important to purchase an adhesive made by well-known manufacturers from an authorized representative. There is a good chance of buying fake glue that is not formulated for use in these situations.

The end board is manufactured according to the following principle.

- The plank workpiece is sawn into longitudinal bars. Their cross-section, depending on the need and the thickness of the future board, can be square or rectangular.

- The obtained block blanks are rotated around their axis by a quarter of a turn in order to shift the direction of the wood fiber. After that, they stick together.

- After drying, the board obtained as a result of the previous manipulation is cut with a cross cut into subsequent bars, which, after turning by a quarter around their axis, are glued again.

- At the final stage, the procedure of grinding the surface of the board is performed, designed to give it a working condition and presentation.

Self-production

In order to make a cutting board with your own hands, for example, from birch, it is necessary to prepare the corresponding drawings and a solid board from this wood.Its width should be sufficient to provide an optimal working space for the future board. All actions can be divided into specific steps.

- The board must go through an initial preparation procedure. Within its framework, the removal of protruding knots, lateral bark, processing with a plane is carried out.

- After that, you can start sawing with a circular saw, on which the rip fence is pre-set. The presence of this stop is mandatory, since it helps to perform rip sawing as smoothly as possible and provides a safety factor for using the machine. The distance between the stop and the cutting blade of the circular saw should correspond to the width of the blocks onto which the workpiece is opened. This takes into account the error created by the thickness of the saw blade itself.

- After sawing the workpiece into block components, they are glued together. At this stage, grinding of the bars is not allowed, as this can lead to a violation of the correspondence of their shape with respect to each other.

- In the process of joining the bars, they must be squeezed using several clamps, which will ensure the reliability of gluing. After twenty-four hours, the next stage of sawing the workpiece is carried out.

- Sawing is carried out in a direction perpendicular to the lines of the glue joint. Further, the resulting composite bars are glued together according to the principle of parallel fiber abutment. The workpiece is again placed in the clamps.

- After the glue dries, the workpiece is reworked. Within its framework, all the necessary additions are arranged: drilling holes for hanging, milling recesses for handles.

- Then the surface of the cutting board is sanded. For this, a mechanical sanding method is used to achieve the best result. Emery paper with different grain sizes is used as an abrasive.

- The final stage in making the board is to cover it with a protective material. It uses mineral oil or beeswax mixed with linseed oil. This protects the cutting board from moisture and increases its lifespan.

For information on how to independently make an end cutting board from the remains of balusters, see below.