Features and overview of nutcrackers

Today it is not difficult to buy ready-made peeled, salted and toasted nuts in the store. Therefore, many do not even think about the existence of nutcrackers. But those who are in the walnut business or simply grew a walnut tree in their garden are faced with the problem of how to facilitate the tedious and time-consuming labor of extracting tasty kernels from a hard shell. Special devices for splitting will help in this difficult matter, which will be discussed in our article.

general description

A nutcracker is a special mechanism that helps break the hard shells of fruits obtained from certain types of trees or shrubs. The device is better than a simple hammer, because it fixes the nut, preventing it from sliding off at the moment of cracking. The cracked shell remains in the device and does not fly apart in all directions, and the kernel of the nut does not flatten, as is the case from a normal blow with a hard object.

Nutcrackers are small in size, they always have a place in the kitchen. Often, fixtures are given a decorative look, so they can be used as an original gift for any occasion. The mechanisms for cracking nuts are extremely simple, even children can easily master them.

The devices are easy to care for, wash and store, and creative pieces become unusual décor in the dining room or kitchen.

It is difficult to say when the first auxiliary products appeared in this field of activity. The earliest mentions send researchers almost 8 centuries ago - that is how many years of stones with artificial grooves. More than 50 of them were found in Israel near the Dead Sea.Scientists believe that with the help of these devices, people made their work easier when chopping pistachios and almonds.

The famous nutcracker figurines in the form of a human face with a terrible grin appeared at the beginning of the 19th century in Germany. Perhaps they were conceived as tools for opening the shell of nuts, but they were rarely used for their intended purpose. They were sold at Christmas markets as a kind of home decoration for the holiday.

Views

Categories of nutcrackers differ in purpose, in material of manufacture, in varieties of nuts. Devices can be made of wood, metal, less often plastic options, and silver devices can be found as antiques. Most nutcrackers are designed to work with walnuts, it is rare to find separate adaptations for smaller fruits, for example, pine nuts, hazelnuts (hazelnuts) or their cultural counterpart - hazelnuts.

More often they produce universal metal and wooden devices with a grip and emphasis on nuts of different sizes. It is quite possible to find multifunctional appliances that can chop almonds, pistachios, pecans, and acorns or chestnuts. According to the purpose, nutcrackers are household and industrial. There are manual, mechanical and electrical categories. Let's consider them in more detail.

Household

Household appliances are used in everyday life, in conventional kitchens, to crack and extract small quantities of kernels from the shell. They look like miniature handy hand tools. In work, nutcrackers are most often used, working on the following principles:

- pressure is exerted on the nut, laid in the conical bed between two handles connected at one point;

- splitting occurs due to the increasing load at the moment the screw is tightened.

The output of intact (undamaged) cores from a device of any kind is guaranteed up to 80%.

Industrial

These include sophisticated stationary equipment (machine tools) operating from electricity on the principle of cracking nuts using a specially shaped replaceable shaft. The device processes large quantities of nuts in a short time. Bookmarking occurs in large-scale portions, and not one fruit at a time, as in everyday conditions. Robust and reliable devices are able to withstand any load.

At large enterprises, in addition to splitting equipment, a whole line of devices for the processing of kernels is involved - drying cabinet, belt conveyor, vibrating sieve-calibrator (machine for sorting nuts by size) and other electrical devices that facilitate the work of a factory worker. The equipment is capable of processing up to 200 kg of products per hour, receiving up to 70% of whole kernels. Damaged or cracked material is used to make nut butter, sweet paste, additives in confectionery.

Mechanical

Mechanical nut processing machines are suitable for small business applications. They occupy an intermediate link between manual nutcracker and industrial equipment.

The device works without the help of electricity, using human muscle strength, processes up to 30 kg of nuts per hour. It requires little hand effort, but foot-operated mechanisms are sometimes used. This type of equipment costs the entrepreneur much cheaper than industrial equipment, and also takes up little space.

Design options

A nutcracker is not the most necessary thing in the kitchen. In order to interest buyers and offer them not only a practical device, but also a decorative product that can be considered as an original gift, manufacturers began to make devices in the form of animals (squirrels, wolves, dogs, deer), mushrooms, fairytale heroes (dragon). As for human characters, their use began in the 19th century with the famous Nutcracker.

Look at the humor with which the Americans turned to the image of their politician Hillary Clinton. By the way, former US President Bill Clinton, Hillary's husband, was also not ignored by creative craftsmen - his image was used as a corkscrew for opening bottles. A beautiful spherical or hemispherical design is used in the anti-stress device. A nut is laid inside the device. To break it, you need to throw out a maximum of energy, make an effort, hitting a ball against a wall or with a fist on a hemisphere.

The most budgetary device for opening a walnut is a small key, as if borrowed from a clockwork toy. It has a sharp tip, which is pushed between the halves of the shell and, making movements to the right and left, split the nut in half. Beautiful nutcracker "Mushroom", handiwork, made of dense beech wood. It is based on a screw. In the thickened leg there is a hole where you should lay a nut of any size - walnut, almond, forest, you can put a chestnut fruit. Then, grasping the mushroom cap, you need to make rotational movements, twisting the gimbal until you hear the crackle of the shell.

The Dragon nutcracker was produced by the Soviet industry. It was assumed that the nut would be laid in the mouth, and the dragon's body would act as levers of pressure. In practice, it took a lot of effort to crack the shell, and the device itself was used more as a decorative element to decorate the kitchen.

Top manufacturers

The speed and quality of nut cracking depends on the respective devices. Choosing a reliable manufacturer of this type of devices, we get a high percentage of whole cores. The equipment of the well-known French company AMB Rousset and the German company Feucht-Obsttechnik has proven itself well in this area. We offer an overview of popular nut crackers from other manufacturers.

VKTECH

A small device from the VKTECH company belongs to the most reliable household devices for cracking nuts. In the process of work, there is a tenacious fixation of the fruit and a quick splitting of its shell. The steel structure sits comfortably on a wooden stand.

Christopher Kuh

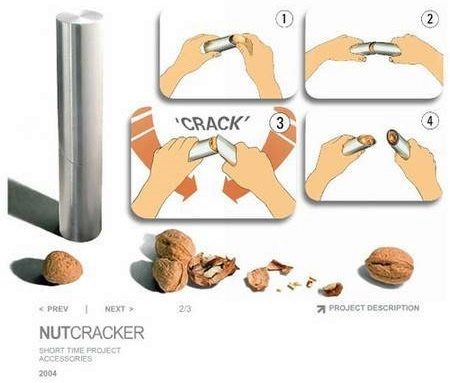

Stylish sophisticated walnut cracker from Christopher Kuh is an aluminum tube. A nut is sent into it, which is held by the internal incisors. It remains only to scroll through the halves of the device and get the finished nucleolus.

Rocket Nutcracker (Little J)

A miniature unusual product cracks nuts of different sizes. Has a plastic body with a bowl for the fruit. The working handle is made of steel and can withstand repeated loads.

The splitting process takes place by simply squeezing the handle.

Mingrizhiguang Home

One of the cheapest devices designed for seeds and small nuts (pistachios, pine nuts). It looks like a pair of scissors (tongs), in which, instead of blades, special notches are made to grip the nut. The fruit should simply be placed in the hole and squeezed by the handles of the device.