How to lubricate skis with paraffin?

Lovers of using skis in winter for a pleasant pastime know that in order for this attribute of outdoor activities to be used to the maximum, it must be lubricated with a substance such as paraffin. Let's try to figure out why you need to paraffin your skis at all, how often you need to do it, how you need to treat new mountain devices with such a substance, and let's figure out the application technologies.

The need to apply paraffin

If you do not delve too seriously into the intricacies of the chemical structure of substances, then paraffins are mixtures based on hydrocarbons. There are quite a few of them, like, for example, the same fluorocarbon substances, but the essence, in principle, they will have the same. The only difference is in the additives that are added to the paraffin composition.

The need to apply them to skis is due to the possibility of a significant increase in slip, and therefore a serious decrease in the possible friction of the skis and the surface. After all, it is known that snow is crystals. And due to the presence of sharp edges, snowflakes seem to impede movement - crumpled, they form a "bristly" type of porridge. And in order to minimize friction as much as possible, they use paraffin treatment of skis.

By the way, the presence of such a lubricant not only does not increase, but also reduces the sliding moment, and accordingly increases the resistance. The movement is carried out at the contact of the base and snow. A paraffinic lubricant has the ability to absorb liquids. Naturally, the substance is absorbed, which makes it possible increase the level of sliding.

Therefore, it will be correct not only to apply paraffin to the skis, but to remove it after a while so that the required amount of the substance is absorbed and provides the required effect, and the excess does not interfere.

Tools and materials

To carry out the procedure under consideration at home, you will need to have such tools and materials on hand.

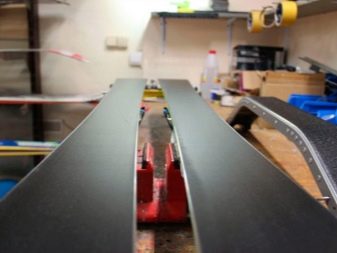

- Ski preparation profile. Usually he has a pair of stops that are equipped with a loop for fastening. If there is no profile, then you can fix the ski on the table with a vise. Or use any type of workbench.

- Iron with a special sole. In principle, you can use the iron without it, but then you should be especially careful.

- Various types of brushes... They are nylon-based to remove hard and soft wax. In addition, they can be used for finishing polishing. Natural can be used to clean up soft paraffin wax. In addition, they can be used to apply accelerating substances. Metal ones allow you to clean the skis of old paraffin and dirt. Polishers allow you to apply powder to a dry surface. But metal brushes are most often used, as well as with nylon of soft to medium hardness.

- Ski scrapers. They can be different: 3-5 millimeters thick, made of plastic and metal, as well as for the gutter.

- Traffic jams... These devices are usually used to rub wax or ointment by hand.

- Ski stones. They usually remove rust around the edges.

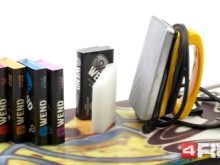

In addition, you will need to have paraffin wax that will be applied to the skis. It comes in several types.

- Briquettes... The most common form. They are easy to apply, and after heat treatment they melt themselves, evenly covering the surface. Note that such substances retain their functionality as long as possible. It is important that the briquettes should never be overheated. They should be melted evenly and not higher than the temperature set by the manufacturer. Otherwise, they will begin to emit substances harmful to humans.

- Paste... This type of paraffin is distinguished by its high ease of application. This must be done using a special applicator, which is usually supplied in the kit. It is then used to polish the surface.

It should be added that the service life of the mixture will depend on the quality of these operations.

- Powder form. Such substances are also called accelerators. They are usually used as an additional measure when the base coat has already been applied. Note that they are significantly more expensive than the above analogs. Therefore, they are often bought by professional athletes and those who take part in competitions.

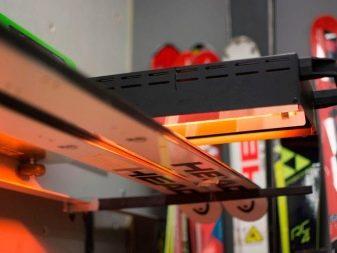

How to lubricate with an iron?

Ironing skis is usually done in between uses. Naturally, before carrying out this process, you should clean the skis and dry them.

And the process of lubrication with liquid paraffins using an iron will look like this.

- We turn on the iron and heat it up to temperature 150 degrees.

- We carry out spraying of a liquid substance onto the sliding layer of the ski... Here we add that different categories of devices have different principles for applying lubricant. For skating devices, the entire sliding surface is lubricated. And the classic fixtures are usually waxed so as to bypass the central area.

- Now skis are needed iron from the toe towards the heel.

- After that, the fixtures require cool and dry at a temperature of at least 0 degrees for about 10 minutes.

- Now apply a layer of paraffin with a brush.previously coated with grease.

All this makes it possible for the heated substance to penetrate into the pores of the plastic, fill them and level the sliding surface as much as possible. And the excess wax is then removed with a brush. Ideally, these steps should be repeated up to 10 times.The difficulty is that brushing not only removes the surface layer, but also removes some of the paraffin that has filled the microcracks. And each new treatment allows you to better tamp the unevenness of the skis, it is better to fill in the irregularities and microcracks.

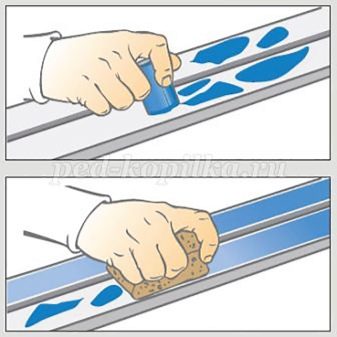

Preparing skis without heat treatment

There is also a cold application of the substance to the skis. Usually, this technology has to be resorted to if there is no iron at hand or there is no time to properly heat treatment.

This will be done as follows:

- first, the skis need to be dried;

- we clean the sliding layer with a brush to remove dust and dirt from the plastic pores;

- wipe everything and let it dry a little;

- now apply a thin layer of grease;

- wait about 3-5 minutes;

- we rub with a cork or pad;

- let stand for another 10 minutes.

If a lot of grease has been applied, then it can be removed with a brush. However, manufacturers claim that with cold waxing, brushing at the end does not matter much. In addition, for normal lubrication in this way, the skis must stand for at least 1 hour and preferably under the influence of sunlight.

And, of course, it should be remembered that this method of waxing is an emergency measure, which still does not give the same effect as classical heat treatment.

A detailed master class on processing skis with paraffin can be found in the following video.