All About Ski Lubricant

Experienced athletes know how important it is to take proper care of their ski equipment. At the same time, not all beginners have an idea that skis require special lubricants, the use of which makes it easier to slide and improves maneuverability on walking trails and downhill slopes.

Why lubricate your skis?

Even three or four decades ago, skis were only wooden.

At that time, they belonged to hunting equipment and were intended for a long ride.

To preserve their appearance and keep them dry, skiers used beeswax, as well as pork fat or a special resin. To give them the necessary maneuverability, it was enough only to smear the lower surface with fat-containing components and paint on top.

Nowadays, synthetic plastic or its combination with wood is used for the production of skis. Semi-plastic and plastic surfaces glide more easily, they are lighter in weight. Moreover, they do not accumulate condensation.

In this regard, among athletes who are just taking their first steps in skiing and alpine skiing, there is an opinion that such equipment does not require specialized care - but this is not the case.

Of course, there is no longer a need for grinding and grinding. However, for good glide on snow, you will need paraffin wax or lubricants similar to it.

There are a number of reasons why ski equipment needs to be handled. When snow interacts with skis, friction arises on the surface of the plastic; in terms of the effect on the material, it can be compared with sanding. This leads to destruction of the working surface and impairment of maneuverability.

In sporting events, speed becomes a decisive factor. Sometimes the champion is separated from the prize-winner by a split second. To increase the sliding parameters and show a high result in the competition, skiers rub the sliding surface with paraffin wax and special waxes.

Lubrication is needed for skis even in case of long-term storage. It will provide reliable preservation, protect against damage during transportation and create an obstacle for aggressive external factors.

If you do not lubricate the ski surface from time to time, then sooner or later dirt will begin to adhere - it will interfere with easy riding and interfere with sliding.

Overview of types of lubricants

In professional skiing, several types of lubricants are used, each of which is intended for a different riding style.

On hold

Grip lubricants are only used for classic walking. The main task of such treatment is to ensure effective adhesion of the shoe to the snow floor during the push-off phase. Competent ski preparation will allow the athlete to correctly push off and move forward.

Such ointments are available in the form of liquid, pasty compositions, solid and semi-solid braces, as well as aerosols and sprays.

Pro skiers go for solid means - they hold better and give more hold.

At the same time, the composition is more demanding in the application technique.

Slip

The names of such ointments indicate that their main functionality is associated with ensuring maximum sliding. The use of impregnations gives good acceleration, prevents snow from sticking to the working surface, and, in addition, repels moisture and dirt. The combination of these factors significantly increases the ski's running characteristics.

Slip compounds are sold in the form of waxes, pastes and liquids. With regard to skating skis, a similar lubricant is used to cover the entire working surface of the ski. In the classics, it is applied exclusively in the heel area and on the toe.

For grip

For skating and classic skis, a grip is required in some cases. This lubricant is used when walking on wet snow, it works as an accelerator. This protective coating prevents the foot from slipping backwards. The composition is applied 80 cm from the heel towards the toe - this processing option is considered optimal for wooden surfaces.

Top manufacturers

For professional athletes and amateurs of long walking runs, the stores offer a wide selection of lubricants of various forms and functional characteristics.

As a rule, beginners choose cheap formulations.

Professional athletes use branded waxes.

The following brands have proven themselves best.

- Whisty is a Russian-made grease. It is offered in a wide range for any parameters of snow moisture and ambient temperature. The advantages include long-term effect and affordability.

- Briko is a popular premium brand. The manufacturer pays special attention to quality control and testing of finished products. Each composition is selected for certain conditions, so it is not recommended to mix them with each other.

- SWIX - offers the highest quality ointments. The funds are presented in the form of paraffins, liquids, sprays and powders. The line presented by the manufacturer is adapted to different weather conditions.

How to choose ski wax?

Among the entire range of lubricants offered by manufacturers, two basic varieties should be distinguished among the most effective.

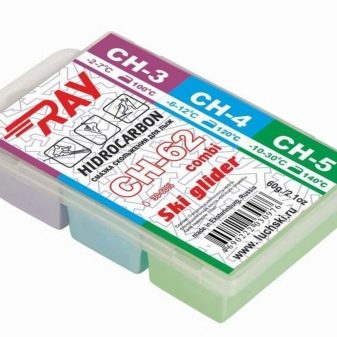

Hydrocarbon wax. Such a composition is one of the most common, it is distinguished by high water-repellent characteristics. It is easy to apply, hot and dry workable.

Hydrocarbon products are sold in a universal version, as well as in formats adapted to specific temperature environments. These waxes are optimal for recreational riding. In professional sports, they can be used in all types of activities, except for competitions. The advantages of the formulations include dirt repellency and fast sliding.

However, such a coating wears off rather quickly, so it must be regularly updated.

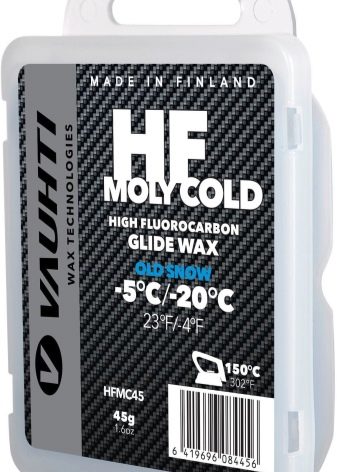

Fluorocarbon wax. These formulations deserve the highest marks for their water repellency properties, which provide fast sliding on snow. They are more expensive than paraffin ointments. However, in the long term, such a lubricant turns out to be a more profitable purchase - it needs to be updated much less frequently than hydrocarbon ones.

This type of impregnation is divided into three categories:

- low fluoride - optimal when snow moisture content is within 60%;

- medium fluoride - used at 60-80%;

- high-fluoride - required with a snow cover moisture content of 80%.

Ointments are thick and liquid. In terms of their functional characteristics, they differ little. And in fact, and in another case, they are necessary to impregnate equipment in order to ensure better glide.

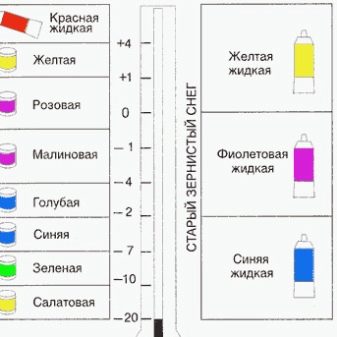

But you need to pay attention to the color coding. It indicates the temperature at which it is recommended to use a particular product:

- lilac - from 0 to - 2;

- blue - from -2 to - 8;

- pale green - from -5 to - 12;

- dark green - from -10 to - 25;

- black - from -15 to -30.

At positive temperatures, it is better to choose liquid textures.

How to apply correctly for different moves?

Let's dwell on the technique of applying ointments.

For classic

According to research, about 2/3 of all ski equipment is for classic riding. The great popularity of models without notches is explained by the fact that they are not pretentious to the quality of the track, can be used for walking, improve coordination of movements and easily "forgive" any flaws in technology.

Mastering classic skiing is the first step in learning to ski.

With all its advantages, this equipment requires complex preparation, which is why the working surface must be processed before the race. This is a complex process, it takes time, special skills, and impressive tools.

You will need:

- a set of ointments for various temperatures;

- washes;

- scrapers;

- brushes;

- rubbing;

- iron.

If you intend to connect your life with skiing, you will have to master the algorithm for applying impregnations. Lovers of the classics use two types of compounds for surface preparation - sliding and holding. The working surface is treated with the first, the last is covered with the second, that is, the area in the middle (it is determined from the heel of the ski boot + 20-25 cm).

The algorithm of actions is as follows.

- First you need to clean up.

- Then the sliding means are distributed on the working surface.

- The block is treated with holding ointment, it is selected taking into account the parameters of the snow and temperature. In warm weather, it is better to give preference to liquid products.

Important: slide and hold aids should not mix with each other.

- After the first layer is applied, it is necessary to give it time to set, after which it is re-treated.

- The final stage of preparing the skis will be polishing with a synthetic brush.

For ridge

The algorithm for preparing equipment for skating has its own characteristics.

- First, as in the case of the classics, a thorough cleaning of the surface is performed.

- Next, you need to warm up the iron to the temperature indicated on the lubricant label.Place the block on a hot surface and gently slide it so that the paraffin layer is redistributed as evenly as possible.

- Move in the direction from the heel of the ski to the toe so that the paraffin is fully melted and covers the working surface of the ski. If you do everything correctly, the surface will cast an even shine.

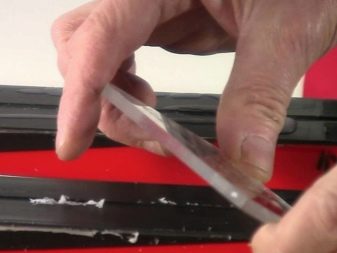

- After the applied impregnation layer has solidified, using a scraper, remove all excess composition. To do this, you need to move against the direction of travel when rolling.

- Finally, they are polished.

Some users prefer so-called "lazy ointments" - gels, sprays and liquids. Their advantages include the speed of application, no need for irons, scrapers and other additional equipment. These compounds are applied in a thin layer, then carefully polished with cork or synthetic rubbing. The skis are then ready to use.

However, with all the obvious advantages, the products of this category are inferior to their solid counterparts in terms of durability.

They come off much faster, especially when the skis are in contact with an icy track or rolling on hard snow. This raises the question of practicality and cost-effectiveness - they are more expensive than solid bars, and the consumption is much higher. Therefore, the practicality and simplicity of such compositions entails impressive expenses.

How do I remove the product?

If you notice that your cross-country skis are not gliding well enough, you should remove the grease. It's easy to do at home.

For easier and faster cleaning of the wax, you should get a plastic scraper or a specialized solvent.

General recommendations in this case are as follows.

- The skis must be fixed on the machine before processing.

- The scraper should be guided from toe to heel. The work should be smooth, even, without changing the pressing force.

- Take special care when handling grooves and edges.

- The traces of the remaining paraffin are removed with a stiff brush.

- To remove dirt and paraffin residues from the inventory, we recommend hot technique - this will require a special iron.

In conclusion, we will give some recommendations for beginner athletes. There are situations when the preparation of the skis is done correctly, but they still give a weak roll. Let's consider typical problems.

The ski slips back. This happens when the composition of the holding does not correspond to the actual temperature, avid skiers call this phenomenon "not to get into the ointment." Another reason for this trouble is the insufficient treatment of the pad area.

Skis give poor glide. There can be two reasons - either the sliding lubricant was chosen incorrectly, or it was applied beyond the boundaries of the pad.

Ice forms on skis, snow sticks. This happens when too "warm" ointment is applied to the pad area, the lubricant layer is not dense enough, or its shelf life has expired.