Buffs for nails: types, selection and use

One of those tools that allow you to achieve the perfect appearance of your nails is buff - a special type of nail file that has a number of remarkable features. Due to the many types of this device, it can be used in a variety of situations, often requiring the utmost care from the performer. It is not difficult to achieve the optimal result with the help of a buff: it is enough to make the right choice of this tool and adhere to the basic recommendations for its use.

What it is?

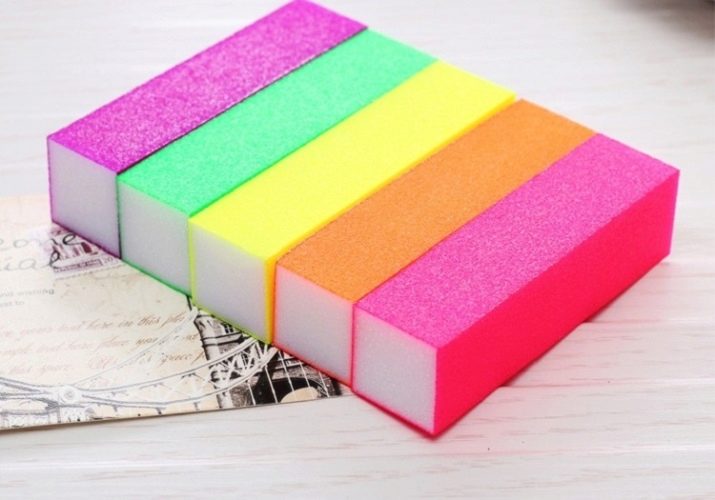

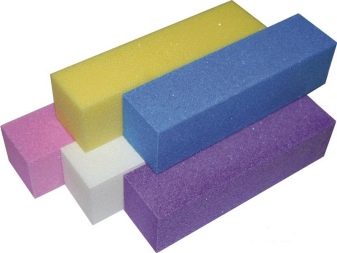

The first feature that distinguishes a buff from a regular file is its shape. Most often it looks like an elongated bar (parallelepiped) with a large working surface area. The materials from which such devices are made also deserve attention: due to their properties, they gently affect the nail plates, and therefore are successfully used to solve the most delicate problems.

The validity of this thesis is confirmed by the name of the described tool, derived from the English verb "buff" - "to polish".

In addition to giving the nails a spectacular shine, the device in question can be used to shape the outlines and high-quality grinding of the processed plates. The latter procedure is especially important: it provides for the elimination of a variety of surface defects, and therefore provides high-quality adhesion and long-term wearing of decorative coatings.It is worth mentioning the versatility of buffs, which allows them to be used not only in specialized salons, but also at home.

As for the working resource of the described tools, it is in a fairly wide range. Depending on the specifics of the situation and personal preferences, the performer can use both one- and multiple-use buffs.

The use of the latter in salons has become possible thanks to sterilizers - devices that provide complete disinfection of the instruments used.

Views

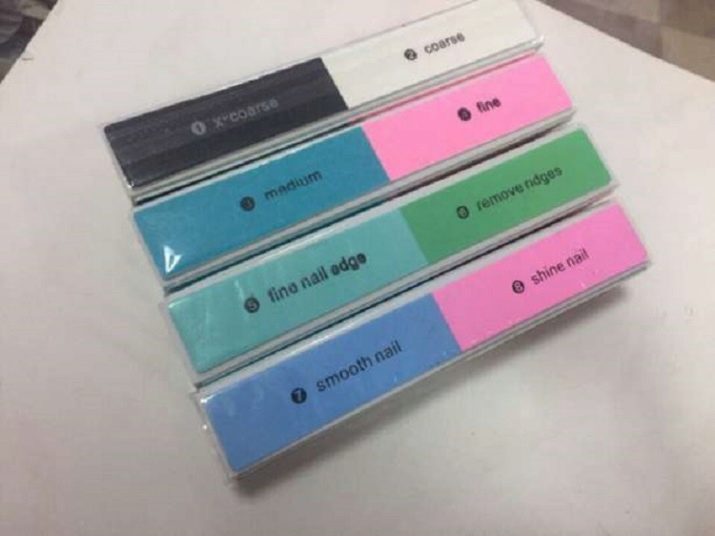

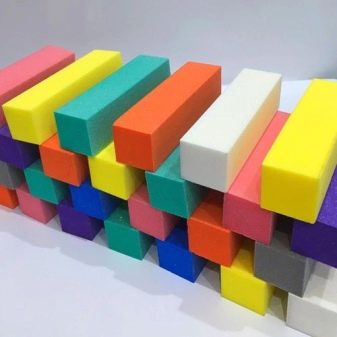

To date, manufacturers offer nail buffs with two, three or four working surfaces. The latter option is considered the most versatile, as it allows you to solve the widest range of tasks.

Often these tools have numbered edges, so that a suitable work surface is selected with the least time:

- the first, designed to give the nails the desired shape;

- the second, by means of which the unevenness of the processed plates is eliminated;

- the third, providing high-quality grinding;

- the fourth, with the help of which the nails are polished to a shine.

Using such a buff, you can not only achieve the desired result, but also significantly save money.

Material

Another criterion on the basis of which various types of buffs are distinguished is the composition of the working surface. It can involve the use of many materials, the most popular of which are the following.

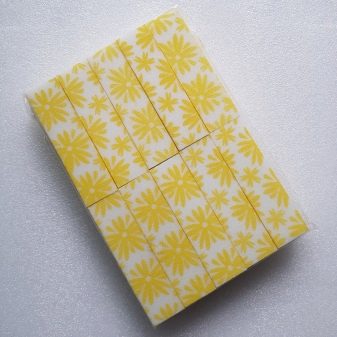

- Polyethylene foam. The most popular option, equally successfully used by both specialists in salons and non-professionals at home. First of all, this is due to the resistance to wear and the democratic cost of tools made of this material. Another obvious advantage of polyethylene foam buffs is ease of maintenance and the possibility of regular disinfection, which does not damage the instrument.

- Suede leather. A distinctive feature of such devices is the presence of a handle, which ensures maximum ease of use. Like the ones described above, suede buffs are used in salons and at home, and their main drawback is the complexity of disinfection, which involves the use of a special cabinet.

- Textile. The use of this material makes the tools light and flexible, which naturally affects the ease of use. Such devices are very delicate, and therefore experts recommend using them for polishing thin natural nails. There are two drawbacks to tissue devices - the impossibility of full disinfection in the absence of special equipment and a relatively high price.

Practice shows that the last type of buffs allows you to polish your nails at maximum speed. In addition, the use of a fabric tool is justified in situations where it is necessary to achieve the ideal quality of the processed surface.

Grain

Special attention should be paid to the surface features of the tools under consideration, which determine the specifics of their application. To classify buffs according to this principle, the concept of grain size is used - the number of abrasive particles (grit) located per unit area.

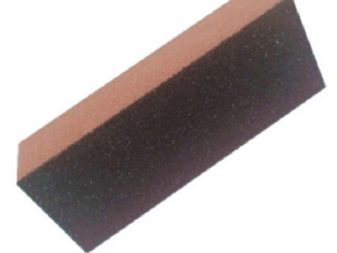

- 60–80. Such devices are classified as coarse. They are used when performing a pedicure or for the initial treatment of artificial nails on the hands. The main qualities of such instruments are rigidity and rudeness.

- 100–150. This value of the grain size of the buff allows it to be used for the correction of extended nails. Through such devices, you can get rid of the vast majority of irregularities. In addition, they polish the nail plates on the feet, achieving an excellent result.

- 150–240. A buff with such a graininess is needed for delicate processing of artificial nails or careful sawing of natural plates.

- 300–500. Tools with the specified abrasiveness value are used to give an effective shine to natural nails of normal thickness and strength.

If the polished plates are too thin, brittle and prone to delamination, the performer needs to use a buff with a grain size of 500 grit or more. The use of such a tool makes the appearance of nails flawless and negates the likelihood of their mechanical damage.

How to choose?

In order for the polishing bar for nails to fully meet the expectations of its owner, the latter should take into account the specifics of the tasks for which the product is purchased. When choosing the right tool, it is advisable to adhere to several recommendations.

- The smaller the thickness of the nail plate, the larger the numerical value indicated on the packaging of the purchased product should be.

- In order to save as much money as possible, it is reasonable to buy buffs with the maximum operational resource.

- If the budget allows, it is worth acquiring several devices made of different materials and with varying degrees of abrasiveness.

By following this advice, you can solve a wide variety of tasks using the tools that are most suitable for them.

And also you should not buy too cheap buffs - products of dubious origin, the quality of which leaves much to be desired. Experience shows that such devices fall into disrepair very quickly, not justifying the money spent on them.

How to use?

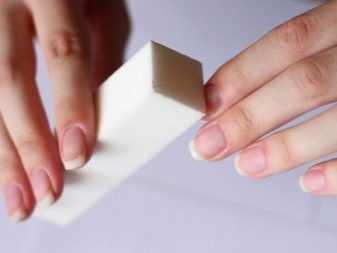

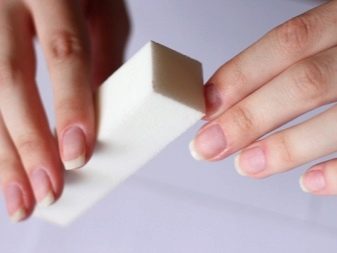

There are several basic rules, following which allows you to buff nails with an optimal result:

- the working surface of the tool should handle the largest possible area of the nail plate;

- performing processing, it is advisable to reduce the number of unnecessary movements to a minimum (in order to avoid delamination of the nail);

- during the polishing of the plate, the initially selected direction should not be changed;

- procedures using a buff should not be frequent (to avoid thinning nails, this tool can be used once every 7-10 days or less).

Before starting the treatment of the nail plates, it is advisable to lubricate them with a small amount of nourishing cream. This step is extremely simple and at the same time important, since its implementation allows you to achieve the best visual result.

... In addition, after polishing, you should treat your nails with products that strengthen them and prevent delamination.

Experts advise against neglecting "sealing" - a simple procedure involving the application of beeswax or a few drops of any essential oil to the ends of the nail plates.

How to sterilize?

One of the most important conditions that must be taken into account by the owners of nail buffs is the disinfection of the equipment used. This is especially true for salon craftsmen who prefer reusable instruments to disposable ones. To avoid the spread of pathogenic microflora, buffs should be processed after each client, leaving them in a disinfectant solution for 15–20 minutes.

An alternative solution is the use of special devices - sterilizers equipped with ultraviolet lamps.

Special attention should be paid to instruments made of soft materials and fabrics. Given the increased sensitivity of such buffs to moisture, they cannot be treated with disinfecting liquids. Ignoring this rule leads to delamination and deformation of the tool, making it unsuitable for further use.

In conclusion, it remains to state that the growing popularity of buffs for manicure and pedicure is explained by their many advantages with a minimum number of disadvantages.The truth of this is confirmed by both masters and non-professionals who want to achieve the optimal result with convenience and the lowest time costs.

All about nail buffs, see the video below.