Choosing a coconut mattress

Coconut mattress is the choice of people who do not sleep on anything. These users value their health too much to waste on cheap sleeping products. It is fundamentally important for them that the mattress is moderately hard, very durable and highly environmentally friendly.

Advantages and disadvantages

Coconut fiber (or shavings) is a natural material that is tough and clean - compared to industrial synthetics, which are sometimes produced, saving on materials and technologies. But, along with the naturalness of the composition, coconut fiber has the following positive qualities: high rigidity, resistance to wetting, breathability (easy to ventilate, dry), low allergenicity.

Mites, mold, fungi, and most microbes do not grow in coconut. Coconut retains heat well, but is also a "breathable" material.

If the production technology has not been violated, the materials have not been saved, then such a product will serve for many years - subject to the rules of operation.

Disadvantages of coconut fiber - the smell of rubber from coconut supplemented with latex additives. Some manufacturers, in pursuit of constant superprofits, "flavor" with phenol, melamine, formaldehyde and other additives. Such mattresses - with insufficient careful consideration, hasty selection - can subsequently become the cause of sluggish health problems. For example, bring a person to vegetative-somatic disorders or, even worse, cause cancer. Better sometimes to overlook and overpay, than to overlook and save money, but suffer.

Especially fakes with coconut coir are dangerous to the health of children and adolescents - they use woolen, silk, linen materials, and they are based not on coir and latex, but on a spring block of increased rigidity with a large number of springs. Another disadvantage of coir mattresses is the extremely high price, especially for products with really 100% genuine coconut that does not contain synthetics.

Comparison with other fillers

T. n. bikokos - coir, into which fiber fibers are woven. The production process is based on high temperature processing, without the use of synthetic adhesives. The uniformity and great strength, the durability of the bikokos - in comparison with a simple coconut - is quite noticeable.

Felt is no better than coconut in properties. It differs only in its lower cost. But the era of felt mattresses is passing - synthetic foam rubber has replaced natural felt. Felt was used to stuff mattresses in the USSR era - springs were used there. Felt mattresses are still being produced, but the advertising lobby of more expensive (and often superior in terms of heat retention) fillers has done its job. Felt mattresses are purchased only by owners of hospitals and hotels in order to reduce the costs of maintaining and operating a particular facility.

In order for the coir to become a slab layer, latex and other synthetics are used as a form-forming filler. Felt mattresses do not require separate synthetic additives for structural formation of the required layers. Unlike coconut, felt is good at absorbing odors and dust. Mites and mold start in felt products - in order to exclude this possibility, a very dense sheathing of the felt layers will be required, the integrity of which must be monitored regularly. One small hole, loosening the threads from which the covering material is woven, will open the way for ticks and bugs.

In addition to the above, felt is cheaper than coconut, since its production does not require exotic raw materials, such as coconut. Sisal is used as a substitute for coir. Compared to coir, it is moderately hard. Sisal fiber is obtained from the pulp of a cactus - it often replaces coconut in countries where the original cultivation of a coconut tree is impossible due to the peculiarities of the local climate. However, the stiffness of sisal is superior to felt and other natural fibers.

Coir species

There are two versions of coconut litter. The fact is that in order to extract super-profits, the coir is processed. Completely unmodified coconut fiber, with a truly unrivaled durability, mattress manufacturers do not let on the market. Initially, coconuts are soaked in water for almost a year. Then the coir is extracted from the soaked raw material manually - by combing out. It is sorted and dried.

Only batches of soft and short fibers are sent to mattress products. If manufacturers used only tough and long fibrous yarns, they would simply go broke, as the demand for such durable mattresses would quickly fall. To get a slab from coir, its fibers are connected in one of two ways.

Pressed

This method of processing involves piercing the fiber with multiple needles. This "bristle" causes the fibers to become tangled and intertwined. The disadvantage is the lack of strength in the pressed coir board.

The material processed in this way loses its spring properties, crumbles and is sprayed.

Latex

Latex threads are implanted into the coir fibers. Latex prevents the coir from prematurely crumbling from numerous squeezes and stretches. As a rule, latex in fiber contains only 30-50%. Latex smells like rubber - it is from this smell that you can guess that it is still present in the coir.

Hardness of mattresses

The more coir in the mattress, the harder it is. This means that a fiber made entirely of coconut is too tough. But this rigidity is not good for this material: pure coconut does not have a long-term effect of complete restoration of its shape after forced deformation from the side of a sitting (lying) person.

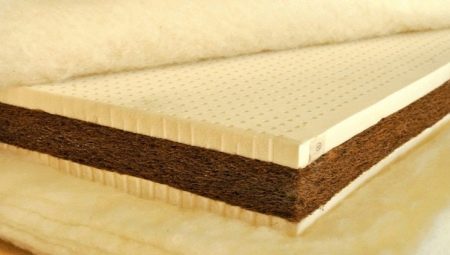

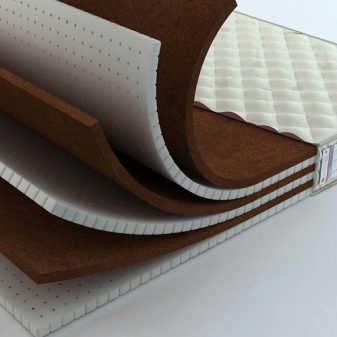

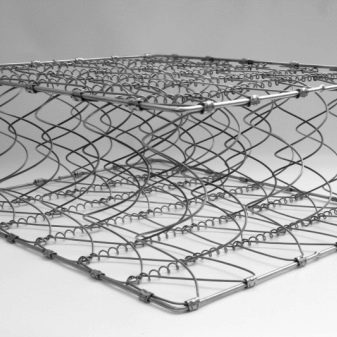

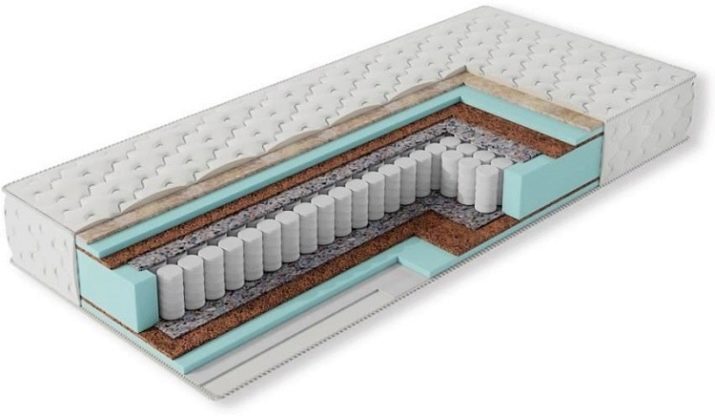

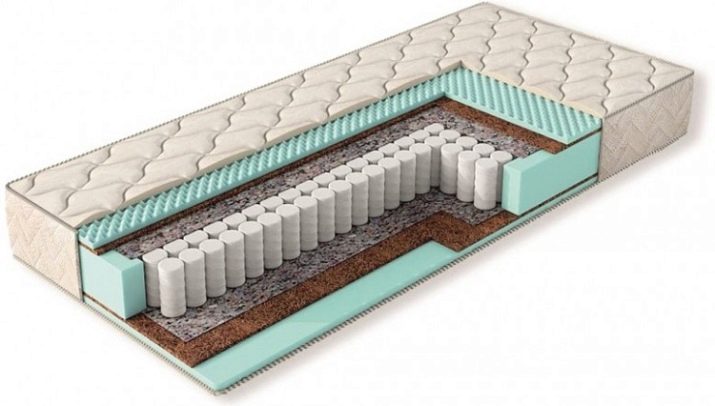

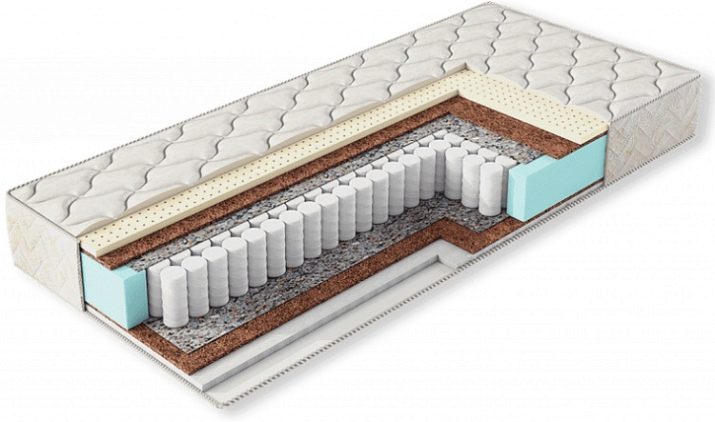

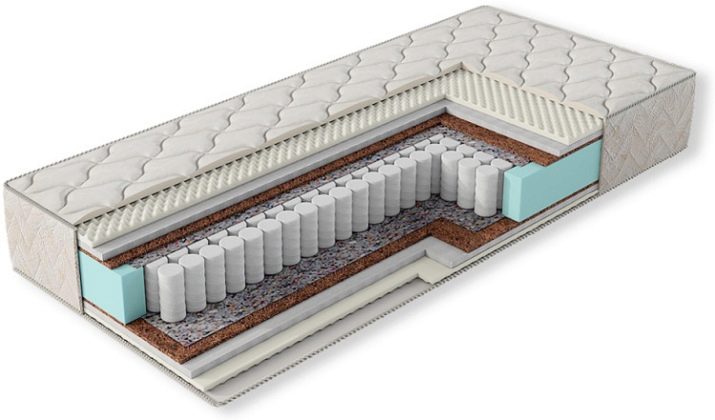

However, the firmness of a mattress, which does contain latex, can be reinforced with interconnected or independent springs that form a single unit. The structure of a rigid double-sided mattress in section is as follows: a layer of upper casing, a layer of latex (1 cm), a layer of latex coir (5 cm), an inner protective layer, a spring block (15 cm), another layer of protection against steel springs, coir, latex (layers with the same thickness as in the previous case), top sheathing.

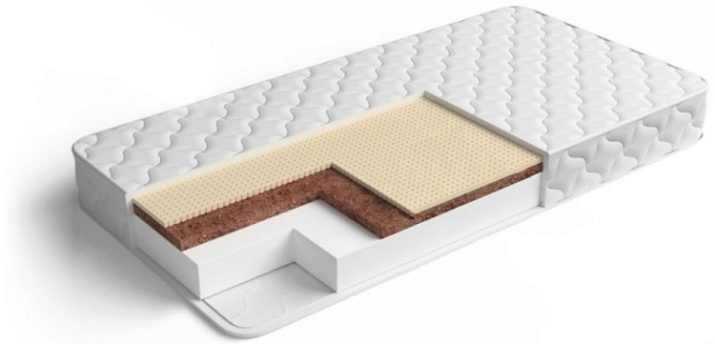

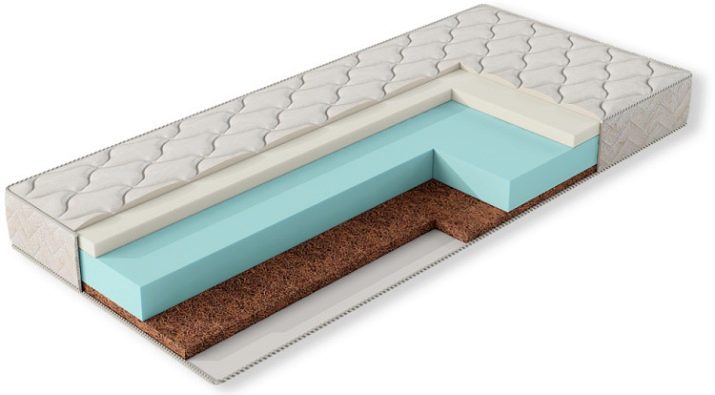

To obtain a semi-hard mattress, the manufacturer removes the spring block from the product, reduces the coir layer to 3-4 cm, simultaneously increasing the latex layer to 2-3. Mattresses - due to the lack of a spring block - are 10 or more centimeters thinner than their spring counterparts. In order for the mattress to become relatively soft with below average hardness, the coir layer is made 2-3 cm each, and the latex layer - up to 3-4 cm. These layers alternate with each other and form a two-component (not counting the outer sheathing) layered "pie" which layers of coir lie between layers of latex.

Five layers - all the same 3 cm each - add up to 15 cm of filler: two layers - coir (intermediate) and three - latex (setting a reduced level of rigidity). If the coir is reduced to 1-2 cm, and the latex is increased to 4-5, then you will get an almost completely soft mattress. Such mattresses are mainly bought by people of retirement age - after the age of 60, the aging process is fully manifested.

It is not possible to completely remove the coir - otherwise it is already a purely latex product that has nothing to do with coir.

Dimensions (edit)

Thin mattresses are only a few centimeters thick. They only use coira. They are well appreciated by people who are prescribed by the doctor to straighten the spine more often on a hard surface. For the manufacture of such a mattress, only the upper casing and a coir plate with a thickness of not more than 5 cm are sufficient. Such mattresses are purchased for children and adolescents - their vertebrae are actively formed, and for the straightness of the skeleton and spine, it is a hard surface that suits them.

Mattresses of medium thickness - 5-20 cm can be of different firmness on each side (the "latex" side is softer than the "coconut"), and with a constant one. In the second case, the filler is a layered "cake" - like "coira-latex-coira" or "latex-coira-latex". Mattresses 25 cm thick contain five such layers, about 20 cm - four, and these layers alternate in different ways.

The order of alternation depends on the make and model of the mattress. Some models of mattresses of medium thickness contain between the single layers of latex and coir - one layer on each flat side - a spring block. The structure of the springs - "bonnel" or independent - is determined by the specific brand and model of the mattress. In the case of thick mattresses, some manufacturers use felt and foam rubber as the middle layer. This allows you to reduce the cost of producing coir mattresses - in order to obtain a certain rigidity, plates of coir with a thickness of no more than 5 cm are placed above and below. One or more modular spring blocks are added to the spring mattresses.

For example, the central block is placed of the "bonnel" type, the outer ones, each on its side closer to the surface of the product, are independent. But such modifications are rare - mainly in Chinese products.

The latter is done in order to simplify, reduce the cost and speed up production, without significantly rearranging the work of the mattress assembly conveyor. At the same time, it is possible to use layers and spring blocks that have not previously passed the mandatory certification.

Along with the thickness of the mattress, the second important parameter of the coir product - like any other - is the size in terms of the occupied area. Single-bed models start at 80x200 cm.Typical, more average modification - 90x200. Half-sleeping mattresses - 130x200, 140x200, 150x200. Double rooms with minimum comfort - 160x200. Double with maximum comfort - 2 * 2 m.

The length in most cases is recommended at least 2 m, while the maximum dimensions reach 2.4 m.

Top Models

We list some of the popular models that are considered to be some of the best.

- Eco-15 - height 20 cm, weight of a person - up to 110 kg, size - from 80 * 190 cm. Independent springs. Materials: coir, foam rubber, cotton and woolen fabric as a lining. Sheep wool is used in the product. Jacquard cover. Coir thickness - 1 cm. Foam rubber - 2 cm. Medium hardness. The largest model is 2 * 2 m.

- "Eco Cake 2" - height 21 cm, size from 80 * 190 cm, jacquard cover, load - up to 140 kg. Latex - 2 cm, coir - 4. High rigidity, synthetic foam (not foam rubber) 14 cm. Size - up to 190 * 200 cm.

- "Vivien" - coconut, spunbond, foam rubber, load - up to 100 kg. Thickness - 22 cm. Block of independent springs. Sizes - up to 2 * 2 m. Jacquard cover.

- "Giotto" - a product with a thickness of 20 cm. High rigidity. Load - up to 120 kg. Independent springs. Size - 80 * 190 cm. Cover - jacquard, synthetic winterizer. Stuffing materials - coir, felt, foam rubber around the perimeter. The maximum area of the product is 2 * 2 m.

- "Corsica Strutto" - thickness 20 cm, load weight up to 110 kg. An independent rigid configuration makes it possible to decide which side to which partner to lie down on. Naturally latexed coir, jacquard-synthetic winterizer cover, interlayer made of struttofiber. Medium hardness - suitable for most users. It is an orthopedic product. The padding is completely natural: foam rubber, silicone and synthetic rubber are not used.

- Tenerife - a product that can withstand a load of up to 110 kg, size - from 80 * 190 cm. Thickness - 17 cm. Contains a layer that "remembers" the contours of the body. High-density foam rubber, coir, jacquard-sintepon cover. The stiffness ranges from high to low, allowing users to effectively determine which side to sleep on.

- "Diana" - thickness 26 cm, withstands a load of up to 100 kg. Independent springs, orthopedics, coconut coir, struttofiber, "memory for the user's body", spunbond, foam rubber layer around the perimeter, medium stiffness. Sizes - from 80 * 190 cm to 2 * 2 m.

How to choose?

For the right choice of a high quality orthopedic mattress, be guided by the following characteristics.

- Usability. Make sure that this particular model is convenient for you, sit down, lie on it - a good sign that the store allows such an opportunity to check. Avoid products that are positioned as necessarily paid for when testing and printing packaging - there is a great chance of getting a product that will not turn out to be 100% what you imagined it to be (in terms of parameters).

- Rigidity. The coir layer determines how firm the coconut mattress is. One centimeter of coir is medium hardness, three or more - high. Heavyweights choose a mattress with increased rigidity.

- Dimensions. Do not choose a back-to-back mattress. Because the head or legs, when you toss and turn in a dream, hang down - you have to lie on your side with your legs tucked in. If your height is 190 cm, then the mattress is recommended with a length of 2 m. The regularity is as follows: add at least 10 cm to your height. A pillow that is too short can fall off when you stretch out on it.

- Coating texture, possible odor. Ideal if the product does not emit any odors. Bikokos smells like rubber (contains artificial latex) - but natural latex, on the other hand, is almost odorless. The structure of the coating should be light and pleasant to the touch, it should not rub or unnecessarily irritate the skin.

A coconut mattress is suitable for people whose health initially did not differ in the absence of any diseases. Most of the common problems with the spine - scoliosis, osteochondrosis, sciatica - can be treated.It is almost impossible to reverse the irreversible processes that have affected the cartilage and, possibly, the bony bodies of the vertebrae in an adult.

But it is possible to correct the condition, to support the patient, and one of these methods is the correct choice of mattress in terms of rigidity. With the right choice of the product, the therapeutic and massage effect is ensured - the back pain will disappear.

How to care?

It is strictly forbidden to roll the mattresses. Soft fillers are perforated and deformed - moreover, irreversibly. Springs simply break - neither independent nor interconnected spring blocks tolerate such deformations. Place the mattress in an upright or horizontal (ribbed) position. Storing the product in an upright position can also spoil it.

When purchasing a new product, ventilate and dry it - before laying it out on the bed. This will get rid of the "factory" smell, which is not good for any person. To protect the mattress from dirt, use an additional cover - a mattress topper.

Coir cannot be washed - the fibers will quickly wear out and become unusable from the chemicals that make up any washing powder.

Flip the garment upside down every two months to help you last longer. A two-sided product can be turned over completely, a one-sided product can be turned 180 degrees. You can vacuum any mattress. But taking it to dry cleaning is not always: make sure that the company, which has this service, provides for non-aggressive cleaning of the coating, which excludes the rapid wear and tear of the coconut fiber.

No acids or alkalis should be used - dry cleaning with them will make the coconut fibers unnecessarily brittle. Only light cleaning is allowed with ammonia water, soda solution, liquid soap and some other reagents of moderate action. If you follow all of the above recommendations, then the mattress will last more than one decade.