All about mattresses with independent springs

Good sleep depends not only on the health of a person's spine, but also on the quality of his sleep. The latter depends on many factors: the absence of noise, the amount of fresh air in the room, the softness of the bed linen and the properties of the mattress. Let's talk about comfortable mattresses with independent springs.

What it is?

Today, mattress manufacturers are doing everything possible to ensure that the products provide the necessary support for the human spine, taking into account its physiology and the degree of activity during sleep. Mattresses with independent springs are a revolutionary invention of the 21st century. They are suitable for people with different weights and back problems. Such products do not cause discomfort to sleeping people in the slightest sound.

If we compare mattresses with an independent spring block with dependent ones, the key difference will be the presence in the first of special insulating covers for each spring. The difference between the two types of products is that the springs of the dependent block are interconnected in one structure. At the slightest movement from either side, the entire block will vibrate.

The independent unit is distinguished, first of all, by the absence of such vibrations, which allows one of the sleeping people to get up or turn around without disturbing the other.

Additional insulation helps extend the life of your high-value purchase. Mattresses are selected depending on the purpose and physiological characteristics of the users. You can determine how many springs should be in the product by discussing these points with a consultant.

Compared to a combined unit, mattresses with independent elements have significant advantages:

- lack of noise effects when driving due to the presence of fabric covers on each spring;

- the ability to withstand a large load due to an additional fixing layer of filler;

- the ability to distribute the load evenly and maintain the natural position of the spine;

- the presence of a relaxing effect;

- long service life due to high quality materials and fillers;

- the presence of a shock-absorbing effect with a large difference in the weight of the sleeping people.

The main disadvantages.

- High price. Many buyers are discouraged by this indicator, although in practice the purchase pays off within six months.

- Low quality counterfeits are common on the market. When buying, it is important to test the mattress and examine it carefully.

- The materials used to make cheap mattresses do not have a high level of durability. For this reason, it is important to purchase goods from trusted sellers, otherwise the best option would be to buy a different type of mattress than a cheap one.

The presence of several disadvantages and the described advantages does not mean that you should immediately buy this type of product. It is important to focus on your own characteristics and needs.

Description of species

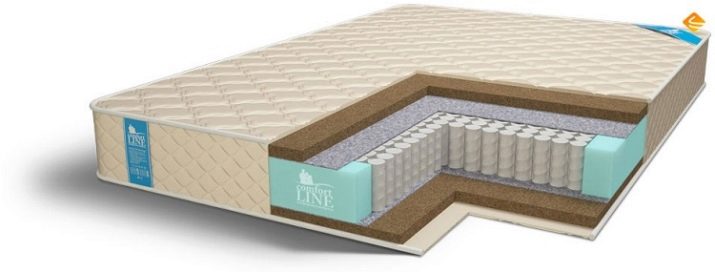

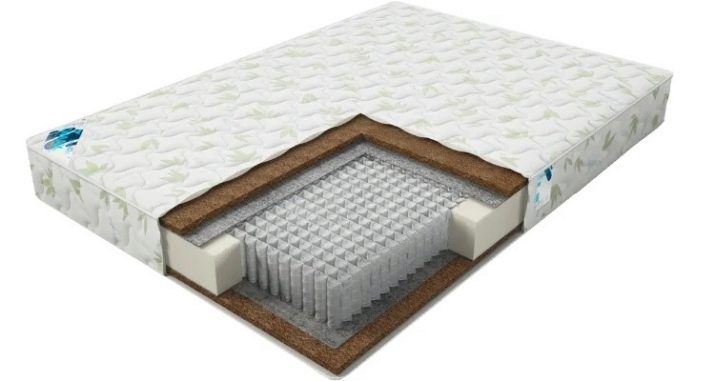

Manufacturers of mattresses with independent springs regularly modify their products, adapting them to the needs of customers. For example, products can be distinguished according to the degree of rigidity: high, low and medium. To create a solid surface, an additional layer is added to the product from coconut coir. Products with a low degree of rigidity are made without coir. There are many types of such goods, among which it is important to highlight two: by the type of construction and by the level of orthopedic effect.

By type of construction

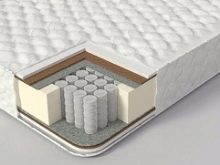

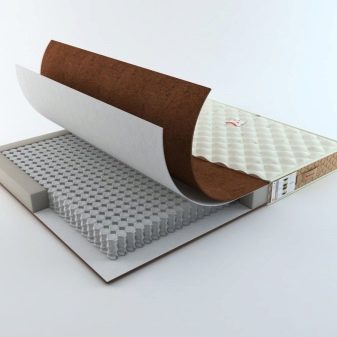

Products with an independent spring block Is a construction of many elements and layers to ensure maximum sleep comfort. Each of the component parts of the product is responsible for performing a certain function, without which the effect of load distribution will not work.

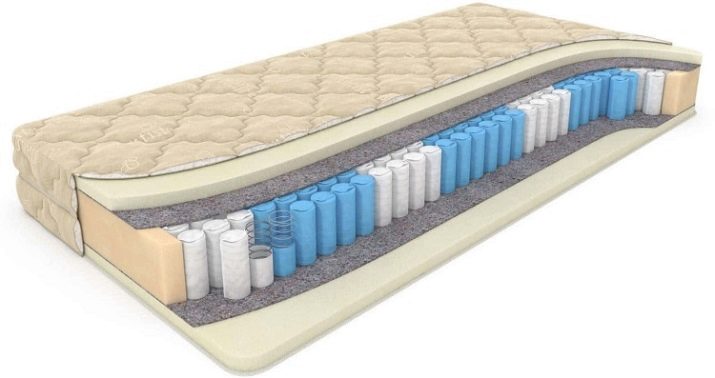

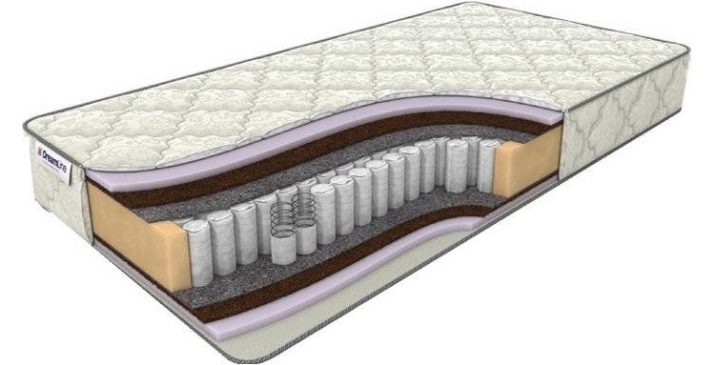

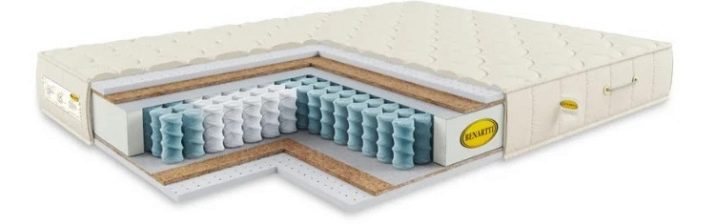

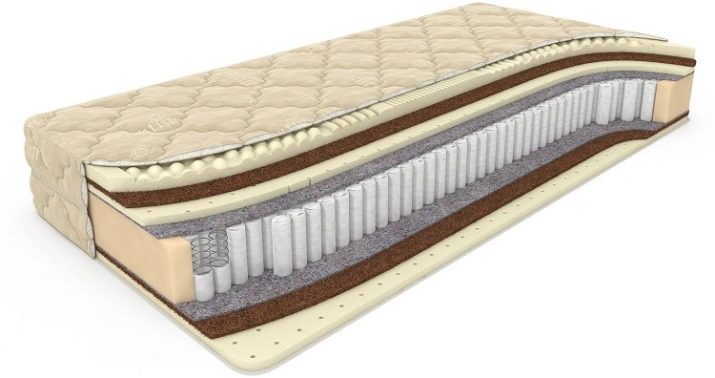

Components of the mattress structure with an independent spring unit.

- A block of springs isolated with special covers.

- Foam side walls, to create the frame.

- Fillers made from durable synthetic or natural ingredients. Fillers are responsible for the degree of hardness of the finished product. Depending on the type of construction, one or several fillers can be used.

- External linen cover, to increase the comfort of sleep and increase the wear resistance of the product.

An important role, both in the distribution of the load and in the creation of the amortization effect, is played by the types of spring elements themselves:

- zone spring block makes it possible to focus on the weight of each part of the body to create an optimal supportive effect;

- TFK Springs - a block with a large number (256) of independent medium-sized springs;

- micropackage - designed specifically for obese people to compensate and correctly distribute the load, each square meter of the product includes more than a thousand small springy elements;

- "duet" - a combined version with large insulated elements, inside which there are smaller springs, this option is ideal when partners are in different weight categories;

- multipack includes about five hundred medium-sized elements for additional support with excess weight or large dimensions of the sleeper.

By the level of orthopedic effect

The orthopedic effect of a mattress can depend on many factors, ranging from the quality of the raw materials and the density of the materials to the rigidity of the products themselves. Based on the firmness index, mattresses can be divided into the following categories.

- Soft items. These products are made specifically for the elderly and underweight people.The most popular soft ingredients: natural and artificial latex, memory foam. Natural latex is a soft and resilient material with a foam structure in the form of small cells. Artificial latex is a type of polyurethane foam. Memory foam is a kind of filler that is able to take its original shape like foam rubber, of which it is considered a kind.

- Products with a medium degree of hardness - an option that suits most adults and teenagers. Manufacturers purchase the following types of raw materials for medium-hard products: holofiber, struttofiber, polyurethane foam. Holofiber is a series of polyester fibers connected to each other by means of glue, which differ in the vertical type of placement. Structofiber is a material that combines cellulose elements and natural components, providing a softening effect.

- Hard varieties are intended for people whose spine is not yet strong enough. In the production of hard species, a number of materials that increase this indicator are used: sisal, coconut coir, thermal felt and bicocos. Sisal is a filler made from agave leaves. Coira is the brown thin skin of a coconut on the inside. Thermal felt is a high density polyester composition with a number of natural and artificial components. Bikokos includes a low elastic synthetic material combined with coconut coir.

Dimensions and weight

Despite the fact that there are several standard sizes for orthopedic mattress models, many manufacturers are ready to meet customers and make a product that suits them in size:

- 160x200 cm - classic parameters for double products;

- 140x200 cm - a variety created for adult spouses;

- 180x200 - double version for large users;

- 90x200 - single-bed mattress with additional centimeters in width;

- 80x190 - a single product, one of the most common;

- 120x200 - one and a half-bed category product;

- 80x200 - single-bed version, increased in length;

- 90x190 - kind of a single-bed product with an additional size in width;

- 160x80 - orthopedic option for children.

A standard double mattress with orthopedic effect weighs approximately 30 kg. With an increase in the thickness of the product, the weight can increase by another 20 kg.

Parameters that determine the weight of the product:

- type of filler - natural ingredients add weight to the product;

- thickness of the mattress - usually the weight of the product is directly proportional to its thickness, but an allowance should be made for the variety of materials;

- rigidity of the product - here the situation is similar to the thickness of the product.

Rating of the best models

Thanks to their comfort and long service life, models with an independent spring block acquire an increasing number of admirers every year. Manufacturers offer elite and inexpensive products that correspond to the quality of the declared value.

An overview of the quality products that made it to the top for sleep over the past year.

- Comfort Line Hard Classic S1000 - a model created from a latex component containing coconut coir. It has strength and durability. The material is hypoallergenic and has antibacterial properties. 500 medium springs per square meter provide the support you need with a weight of up to 140 kg per berth.

- Dimax Mega Hard - a product with high rigidity allows a load of up to 150 kg. Layers of latex coconut material will provide the desired anatomical effect on each side.

- Dreamline Memory Latex Smart Zone - orthopedic soft model with an independent block, including 7 zones of springs to provide quality support. The model can carry up to 150 kg per seat. The outer material is breathable and the padding has a memory effect for increased comfort.

- Dreamline Eco Foam Hard TFK - medium-hard version, capable of withstanding a load of up to 120 kg per berth.A thermal fiber layer has been added to each side to increase strength.

- Ascona Sleep Style FEEL - a model with no weight restrictions, which is suitable for people with physical inactivity. Thanks to the special micro-massage effect, the muscles of the sleeping person maintain their tone and normal blood circulation is restored. The filler consists of polyester and cotton felt.

- BENARTTI Prime Optima TFK - a medium-hard product, capable of withstanding 130 kg per seat, has an orthopedic effect. Standard latex and coconut composition and jacquard coating for models from this company.

- Dreamline Dream Massage S1000 - bilateral model with orthopedic effect and two types of rigidity. The model contains 500 springs per sq. meter. Contains coir of coconut and latex filler. The set includes a removable soft velor cover. The product has high strength and durability, which can significantly extend the service life.

Nuances of choice

Buying an orthopedic product is a multi-stage process that provides several criteria for selecting a suitable product. The rules for the selection of an orthopedic product for a bed are as follows.

- Choose a product depending on the hardness of the materials. Before going to the store, it is important to assess the health of the person who is going to sleep on the mattress, his age and the degree of mobility during sleep. If a person has postural disorders or spinal diseases, it is very important to choose a product based on this information.

- Take into account the body weight of a sleeping person.

- Measure the length and width of the bed, guide the consultant on the preferred height of the purchase. Tall products will be able to compensate for excess weight, while slim people will suit lower options. The standard height of mattresses with independent springs is 18-19 cm.

- Agree with the consultant the size of the springs and the type of block.

- When selecting the filler material, take into account the degree of rigidity, allergenicity, composition.

By choosing a certain category of orthopedic products, you should pay attention not only to its cost, but also to suit the needs of the user... Often high quality products remain unclaimed due to an error at the selection stage. In addition, you should independently study the characteristics, feel the material and test the mattress.

Varieties with independent springs are usually purchased for a sleeping bed, although there are times when a mattress is needed as a spare bed. In such a case, a product with a minimum height would be a suitable option, which will be conveniently stored in a closet rolled up.

Care rules

The service life of a mattress with independent springs is from 10 to 16 years, provided it is used correctly. Important rules for the care of an orthopedic mattress are as follows.

- Compliance with the size of the bed and the presence of a gap between the plates.

- The need to turn the product over to the other side monthly, after six months of use - once every six months.

- Turn the mattress not only horizontally, but also vertically.

- Availability of ventilation or daily airing of the room.

Despite their large dimensions, mattresses with independent springs can be rolled up and stored rolled up. Of course, it will be quite difficult to roll up tall types, so the need for storage should be taken into account in the selection process.