Beryllium bronze: composition, properties and application

In our review, we will dwell in more detail on the features and physicochemical parameters of the copper-beryllium alloy, better known as beryllium bronze. Let's talk about the physical and chemical characteristics, as well as the field of application of this unique composition.

Definition

Beryllium bronze is a copper-beryllium alloy containing from 0.5 to 3% beryllium, in some cases it is possible to add other impurities. Beryllium bronze is different:

- Increased density and strength, combined with non-magnetic characteristics and a complete absence of sparking.

- It is capable of undergoing any type of processing - cutting and shaping.

- The alloy is widely used for the manufacture of instruments, including musical instruments, as well as precision instruments and bullets for firearms.

- Copper-beryllium has also found its application in aerospace technologies.

Important! Remember that alloys containing any amount of beryllium are highly toxic and pose a hazard to humans during the manufacturing phase.

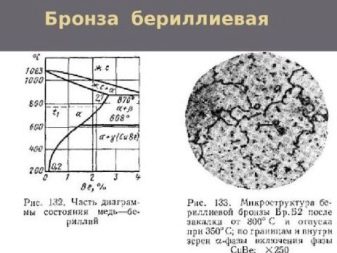

Beryllium bronze belongs to the group of so-called dispersion-hardening compositions... Their distinctive characteristic is the dependence of the degree of solubility of alloying ingredients on heating.

When quenching is performed from a single-phase section in a solid, an excessive number of atoms of the main alloying component is formed in comparison with the equilibrium state of such a system. The resulting concentrated solid solution is characterized by thermodynamic instability and a tendency to decomposition; with an increase in the temperature level, this process is activated. The effect of compaction is explained by the dispersion of the precipitates obtained as a result of the decomposition of substances.

Composition

The chemical formula of beryllium bronze is BrB2, its composition is detailed in the current GOST.

The alloy includes the following ingredients:

- copper 97-98%;

- beryllium 1.9-2.1%;

- nickel 0.2-0.5%;

- less than 0.5% additives.

The most commonly used copper-beryllium compositions containing 2% beryllium, as well as copper-beryllium-cobalt alloys, where the percentage of beryllium does not exceed 0.8%. The first alloy is called high-alloy beryllium bronze, the second belongs to the group of low-alloy grades.

Properties

Beryllium copper has the following physicochemical characteristics.

- Overestimated electrical and thermal conductivity. According to these parameters, the substance is only slightly inferior to copper.

- Increased elastic limit.

- Lack of sparking during mechanical shock.

- High parameters of corrosion resistance, hardness and temporary resistance.

All these characteristics are maximally manifested for all moments when beryllium bronze is subjected to various processing and quenching methods. For example, with artificial aging, such substances reach their ultimate plasticity after quenching, which is carried out at a temperature of about 770 degrees - in this state, beryllium bronze is extremely light.

Typical resistance of the substance corresponds to 450 MPa. This parameter doubles during the processes of plastic deformation of the alloy by 35-50%. As a consequence, after aging, which is carried out immediately after the completion of the hardening process, the mechanical properties of beryllium become extremely high.

The parameters of the copper-beryllium composition, which are fundamental for the industry, are far from being limited to those listed. All bronze alloys, the structure of which includes beryllium, are characterized by high heat resistance - products made from them can function without changing their capabilities at temperatures up to 340 degrees Celsius. And when heated to 500 degrees, the mechanical properties and density of any beryllium bronzes become completely identical in their performance to aluminum, as well as tin-phosphorite compositions at a standard operating temperature of about +20 degrees.

This property allows the use of beryllium bronze for the production of shaped castings of the highest quality.

In most cases, the alloy is produced in the form of semi-finished products that have passed the molding stage. Most often it is a thin tape, strip or wire.

Beryllium alloys are easily amenable to any mechanical processing (cutting, brazing and welding). Although there are some restrictions on carrying out the listed manipulations. Thus, any beryllium alloys should be brazed immediately after mechanical stripping is completed. In this case, be sure to use silver solder, as well as flux. It is important that fluoride salts are always present in the flux itself. In recent years, the so-called vacuum brazing has become widespread - it is carried out under a thick coating of flux. Thus, the unique quality of the product is ensured.

But nowadays, electric arc welding is practically not used when working with beryllium copper, since it has a significant crystallization thermal interval. Welding of seam, as well as spot and roller types in inert media has been mastered in full. It should be added that the specific mechanical characteristics of the material do not allow performing welding work immediately after the heat treatment of bronze - this should certainly be borne in mind when thinking over the technology of their processing.

The following indicator deserves special attention: cooling rate. This indicator should be extremely sharp in order to prevent the decomposition of the supersaturated solid composition. That is why, when selecting working quenching media, first of all, one should proceed from the critical speed indicators.These data confirm that during the quenching of bronze, the maximum cooling rates should be in the range of 500-250 degrees.

Slow processes in this interval lead to early release of the hardener and cause a decrease in the ability to further harden. The critical cooling rate, which allows an optimal combination of physical and technical characteristics to be achieved, corresponds to 30-60 g / s for copper with beryllium added. To achieve the desired value, the alloy is usually quenched in water. In order to reduce the critical velocity parameters, a little cobalt is usually added to the alloy. Minimal additions of such a metal increase the stability of the supercooled solution. Likewise, magnesium impurities can affect the durability of bronze.

Application

Visually, beryllium bronze looks like a colored alloy, which together used in the manufacture of spring elements, wire, rods and some other elements that are required to maintain the configuration. With frequent deformations and constant overloads, such a wire has an increased electrical conductivity, it is used in low-frequency contacts for the manufacture of electrical connectors.

Strong non-magnetic yet non-sparking beryllium copper found wide application in the manufacture of pliers, chisels of knives, hammers and wrenches. Alloy optimal for handling some explosive substances, for example, in grain elevators, oil rigs or in coal mines.

Beryllium-copper alloy is often used to make percussion musical instruments to provide their translational tone and acoustic resonance - usually the material is in demand when creating triangles and tambourines.

Common use of the alloy for cryogenic equipmentused at the lowest temperatures. For example, refrigerated trucks. The relevance of using copper-beryllium in this area is explained by its strength and increased thermal conductivity in this temperature range.

Use the composition for the production of bullets. Although such an application is quite unusual, since a steel bullet is cheaper and at the same time has rather similar characteristics. Copper-beryllium wire is available in several forms at once. It can be curly or flat, round or square; various straight layers, as well as coils or coils are on sale.

Interesting information about beryllium is presented in the following video.