How to distinguish bronze from brass at home?

Often, when purchasing antique jewelry, dishes, figurines from copper alloys, it becomes necessary to identify the metal from which they are made. This is especially important for people who are engaged in casting and melting of highly artistic products and jewelry. But how to distinguish bronze from brass at home, if there is no possibility to conduct an examination in the laboratory.

General characteristics of metals

Brass and bronze are two superficially similar copper-based alloys from which many decorative and technical items are made. Both metals have a low melting point, which allows you to make different products from them with your own hands. Despite the similarities, they have completely different chemical composition, color and physical properties. However, it is rather difficult for an ordinary person not employed in metallurgy to identify them.

Brass

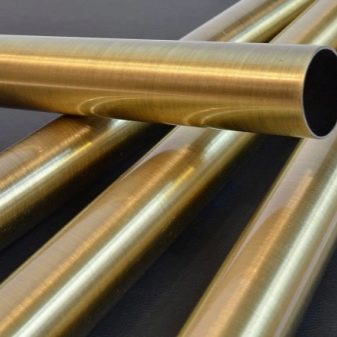

It is based on zinc, sometimes with the addition of other elements (nickel, tin, manganese, lead, iron, bismuth and others). Metal was known long before our era. Thanks to the color reminiscent of gold, ancient Roman coins, various household items and jewelry were minted from brass. In the modern world, the alloy is most often used to obtain steel-brass bimetal, from which artistic products and decorative fittings are made.

Brass is not resistant to abrasion, but is characterized by high ductility and good anti-corrosion properties. Easily lends itself to various types of welding (gas, arc) and easily rolled. Products made from it have a yellowish color and are well polished. It is not ferromagnetic.Particularly popular is a type of wrought brass alloy called tombak. It contains 88-97% copper, and the rest is zinc. Due to its high plasticity, it is widely used in artistic casting, for the manufacture of insignia, wind instruments.

This alloy is often used to imitate gold. Now they make school gold medals from it, coated with a sputtering of real gold.

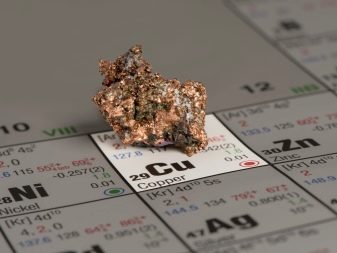

Bronze

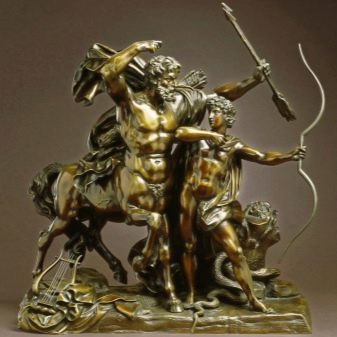

It is a copper alloy, where the main element is tin or other chemical elements (nickel, aluminum, silicon, and the like). But high-quality bronze is obtained only in combination with tin. Metal appeared in human life at the beginning of the Bronze Age. The most ancient products from it date back to the 5th millennium BC. Its classic use in the recent past is the casting of bells and cannons.

In the molten state, the metal has good fluidity, which makes it possible to cast any, even the most complex shapes from it.... Due to its high resistance to mechanical abrasion and corrosion resistance, the material is used in mechanical engineering, rocketry, aviation, and shipbuilding. And due to the fact that the alloy is not exposed to the negative effects of atmospheric phenomena, it is used for casting sculptures, monuments, decorative elements of the exterior.

Comparison criteria

Despite the fact that in metallurgy there are clear criteria for distinguishing these two alloys, in real life an uninformed person hardly identifies them with accuracy.

Composition

Clear differences between metals can only be traced if the alloys do not contain impurities. However, now there are a large number of their varieties, which makes identification difficult. Brass is designated by the letter "L", the subsequent characters in the marking indicate the presence of the main elements and the average copper content in percent. For example, L70 means 70% Cu content, and LAZh60-1-1 consists of 60% copper, 1% aluminum and 1% iron.

In a brass alloy, copper is combined with zinc, which gives the metal plasticity and a low degree of wear resistance. This is the main add-on element, but brass comes in two- and multicomponent. There are different types of it.

- Wrought alloys. They are used in the production of machine parts, pipes, springs.

- Foundries. They are used to make bearings, fittings, devices designed to operate in high temperature and aggressive environments.

- Jewelry brass. It is used for making decorations, medals, decorative elements, art products.

In bronze, copper is alloyed with tin, which makes the metal stronger, stronger and more durable. But sometimes aluminum, beryllium or magnesium are used instead. There are also several types of bronze.

- Tin bronze, in other words "bell". The main alloying element is tin. The alloy has good corrosion resistance and high antifriction properties.

- Tinless alloys... They use other components (aluminum, lead, beryllium, silicon and the like). These alloys are much softer and more ductile. The color of the material depends on the components it contains. For example, aluminum bronze has a characteristic golden yellow color, which is why it has long been used as a substitute for gold for the production of coins and jewelry.

The most famous of the tinless alloys is constantan. This heat-stable metal with high resistivity contains copper (about 59%) with the addition of nickel (39-41%) and manganese (1-2%).

By the way, in the markings of bronze alloys, the percentage of copper is not indicated, it is calculated. For example, BrA9Zh3L contains aluminum - 9% and iron - 3%. The letters "Br" mean bronze, and "L" - foundry.

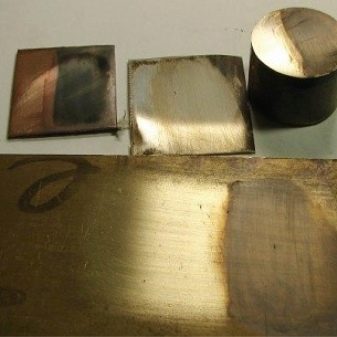

Appearance

Due to its high zinc content, brass is similar in color to real gold. However, the shade directly depends on the percentage of a particular chemical element. Therefore, the range of colors can vary from pinkish red to golden yellow. Typically, brass looks like a gold-yellow metal.

A bronze alloy is distinguished by a silvery-white tone if it contains more than 35% tin. If its content reaches 40%, then the color of the metal is closer to white, reminiscent of steel. Products made of such bronze are silvery with a slight golden tint. If the composition contains a large proportion of copper (more than 85%), then the color of this metal is closer to red or dark brown.

Weight and strength

Brass is a more fragile and less durable material, prone to rapid wear. It is not used where high abrasion resistance is required. Due to the low density of zinc, brass is much lighter than bronze. Bronze is a wear-resistant and durable material. Due to its plasticity, it is the favorite casting alloy of sculptors. It is much harder and stronger than brass. For example, a metal with a 27% tin content turns out to be as hard, heavy and brittle as possible. That is The hardness of bronze depends on the percentage of tin in it. But this statement cannot be applied to tinless alloys.

More precisely, the specific gravity can be calculated by multiplying the density of the metal by the volume of the workpiece.

Properties

Brass needs to be improved, so various additional components are introduced into the alloy. Thanks to this alloying, the casting brass alloy is characterized by resistance to corrosion, low coefficient of friction, increased fluidity, low tendency to liquation, and excellent technological and mechanical properties.

Bronze has high strength properties and a low coefficient of friction. Due to its excellent resistance to the negative effects of aggressive environments, the metal is widely used in shipbuilding and navigation. Copper alloy has a wide range of applications - from decorative interior elements to critical parts.

Price

Brass products are characterized by low cost. It is especially important to know this when handing over scrap metal to the points of receipt of raw materials. However, price is not a determining criterion, as it depends on the concentration of copper. The more it is, the more expensive the metal is. And for bronze, the tin content is also a determining factor. For example, tin bronze is more valuable than silicon bronze.

How to tell at home?

In practice, there are several simple and proven methods to help identify metals.

The heating

Heat treatment helps to distinguish between copper alloys. It is carried out using the flame of a powerful burner. For this, the metal sample is heated to 600-650? С. A fire or burner on a conventional gas stove does not provide sufficient temperature. If an ash deposit (zinc oxide) appears on the surface of the product as a result of the procedure, and the material itself becomes plastic, then it is brass.

When bent, the metal does not break, but bends. Such plasticity and pliability is associated with the presence of zinc in it. If the product becomes hot when heated, but does not change color or other mechanical characteristics, this indicates bronze. When bent, it tends to break.

Filing

The essence of the method consists in determining the alloy by the quality of the chips formed by sawing a metal product. A hacksaw is used as a tool. Brass is sawn in layers, forming curly shavings. And bronze, due to its fragility, is sawn in small flakes, more like dust.

Using a magnet

Not all copper alloys are ferromagnetic. For example, tin and lead tend to be attracted to a magnet, but it has no effect on brass. For this method of testing, a strong magnet (for example, neodymium) is required, which must be brought to products made of different materials one by one. Bronze will stick slightly due to the tin, iron or nickel it contains.The higher the content of these components in the metal, the more the bronze product is prone to magnetization. For example, a metal marked BrAZHN-10-4-4, where the digital designation indicates the content of Fe (4%) and Ni (4%), has the maximum magnetic susceptibility.

Classic brass does not react to neodymium in any way. However, brass alloys containing iron and nickel (LAZH and LAN), respectively, will also be attracted to the magnet. All these facts cast doubt on the effectiveness of the method itself.

Determination by the nature of the fracture

Sometimes, when it is not possible to determine the metal in other ways, this can be done by visual inspection of the fracture site. Brass tends to break with small grains of a whitish or yellowish color. The bronze alloy breaks off in large pieces with a coarse-grained structure. The color in the section has a characteristic reddish tint.

Chemical treatment

Another effective method to distinguish between copper alloys is by exposing them to a chemical reagent. You only need the necessary special equipment and 50% nitric acid (HNO3). Tubes with a mixture of reagent and metal shavings are heated until a white tin precipitate appears, the presence of which indicates bronze. If the liquid remains transparent, then this means that it contains brass.

However, this method is not suitable for tinless alloys. In the absence of nitric acid, it can be replaced with a sea salt solution. In this case, the brass shavings will change their color, and the bronze will remain without visible changes.

Welding machine

In brass, the welding process will be accompanied by the formation of white smoke, formed due to the burnout of zinc. In bronze, as a result of contact with the welding arc, no smoke will be observed.

Determination by weight

This is another method for distinguishing metals. To reveal the difference, it is enough just to weigh bars of the same volume from different alloys in your hands. A bronze specimen will weigh much heavier than a brass piece.

However, the density of the joints also affects the weight of the product. Therefore, it is not always recommended to use weight as a clear criterion for distinguishing between metals. For example, bronze with a low tin content (2-8%) differs in that it will weigh lighter than a brass counterpart.

What is the best choice?

If there is no way to identify the alloy, you can check the metal product in certified centers - and this will be the best choice of method for determining the composition. In such institutions there are compact laboratories where spectral analysis is carried out on special equipment. This method allows you to determine the chemical composition of the material with maximum accuracy. A special tool is used for checking - a steeloscope. The method is distinguished by its high sensitivity and the ability to determine the composition without changing the metal structure.

Typically, metal receiving points also have such equipment. It is used for quick and accurate identification of ferrous and non-ferrous alloys. And also this method is good in that even a small copy is enough to use it.

For how to distinguish between metals, see the next video.