How and at what temperature to melt bronze?

Bronze - the first alloy that people learned to make thousands of years ago. Since then, bronze items have been very popular. Today, modern craftsmen are trying to adapt foundry technologies to domestic conditions, for this it is necessary to know the chemical composition and physical properties of bronze, as well as the technical characteristics of alloys obtained from it, including aluminum bronze.

This article talks about such an important indicator as melting temperature, and also about how to stage-by-stage the process of melting and casting bronze.

Melting temperature

Exists table of melting points of different types of bronze. Before proceeding directly to melting, it is necessary to understand what determines the temperature at which a particular metal begins to melt or completely turns into a liquid state. Bronze is actually a number of different alloys., which include copper as the main component, and other elements as additional (alloying) components.

Such alloying substances can be aluminum, beryllium, tin, silicon and so on. Everything depends on the chemical composition of bronze. physical properties metal, including the melting point. To melt a copper alloy, you need to know it chemical composition, this is the only way to correctly determine the melting point in degrees Celsius. Let's take a look at the melting points.

Pure metal

Although it is extremely unprofitable to produce pure copper, since its technical properties are in many ways inferior to special grades that are produced from this metal in the metallurgical industry, nevertheless, know the melting point of copper is necessary.

Why? The fact is that those grades of copper that are used in the national economy have in their composition a negligible amount of alloying substances, which are considered as impurities. Thus, due to the insignificance of their quantity, the melting temperature of copper grades is close to the melting temperature of pure copper and is approximately 1084.5 degrees Celsius.

As already mentioned, the melting point depends on the composition of the substance, for this reason, the melting point of bronze varies between 900-1140 degrees Celsius.

Mixtures

Tin in bronze reduces the melting temperature of such alloys, it does not exceed 900-950 degrees Celsius.

Tinless, including aluminum bronzes have a wider range of such temperatures, which depend on the chemical composition of the copper alloy. Their melting point is 950-1080 degrees. It should also be borne in mind that bronze has high viscositytherefore it is superheated after final melting to ensure better melt flow. Let's look at the process of melting and casting bronze in stages.

Step-by-step instruction

In handicraft conditions, mainly small bronze items are made, for example, decor elements. More complex parts require high-precision casting, the technology of which is very difficult to implement without a specially adapted for these purposes premisesas well as special equipment... In some cases, it is necessary to resort to fine-tuning the casting to the desired state with the help of straightening at homesuch as removing excess molten material by hand, sanding and polishing the product.

Before proceeding with the melting of the metal, you must prepare the premises and acquire the necessary tools and equipment... The main requirement for the room is the availability of good exhaust ventilation, as well as a floor made of non-combustible materials such as concrete, cement or brick. In the manufacture of small products, these requirements are quite simple to comply with, otherwise you will have to use the garage.

In order to melt bronze at home, it is necessary to purchase a special muffle furnace with the ability to control the temperature, but you can get by with a simple mining, for which charcoal will serve as fuel.

Instrument preparation

A novice caster should purchase or make the following tools.

- A refractory crucible made of refractory material (such as cast iron or steel) is a special vessel with a spout where pieces of molten metal are placed.

- Tools for removing the crucible from the furnace, which minimize the risk of scalding - special hooks and tongs.

- A mold for pouring molten metal, which is made using a flask and a model.

- The flask itself is two boxes that hold the mold filled with the sand.

- A welder's suit or just a very tight apron and gloves, the purpose of which is to protect a person from flying sparks and splashes of molten metal.

After you are convinced of the presence of all of the above, you can proceed directly to melting the bronze.

- Preheat the ovensetting the temperature using the regulator. The temperature depends on the chemical composition of the bronze, as we discussed above. For example, for aluminum bronze, this temperature will be equal to 1040-1084 degrees Celsius.

- This is followed by sure warm up the form, this is done so that the molten metal does not freeze when it enters a cold container.The mold is placed in an oven when it warms up to a temperature of 600 degrees, after which the thermostat is set to the 900 degree position. When the temperature inside the oven rises to 900 degrees, the mold is left to warm up for 3-4 hours, after which it is carefully removed using special devices and cooled to 500 degrees Celsius.

- Place the crucible with pieces of bronze, intended for melting, inside the furnace heated to the desired melting temperature and brought to complete melting of the metal. After that, the crucible is left to overheat for another 5 minutes in order to achieve better metal fluidity and better casting quality.

- Take the crucible out of the furnace or forge with hooks and tongs and start pouring into the mold.

Let's take a look at how to properly make form for obtaining a high quality product. In foundries, such a shape is made using flasks, where a mixture of clay, sand and coal powder is poured. The flask consists of two halves, each of which is a box where the molding sand will be poured.

- First, they take the first box and begin to fill it with the mixture, pouring it in half, place the model inside the box.

- Further, they continue to pour bulk material until they fill the box to the very top. During work, it is required to constantly level and tamp the molding sand.

- Place the second box on top and continue to pour the mixture of clay, sand and coal powder.

- In the second box, it is necessary to provide sprues - holes for pouring molten bronze into the mold.

- When both boxes are filled to the top, separate them with a sharp object. One half of the model is in one drawer, the other half is in the other.

- They carefully take out the model, reconnect both boxes - the resulting void inside is the mold for filling.

Pouring into a mold

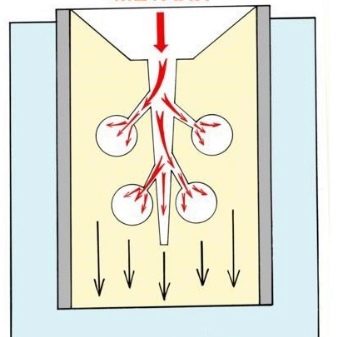

The molten metal is poured in a thin stream from the crucible into casting mold, making sure that the trickle flows continuously. If the part to be cast has a complex outline, you need to use a special centrifuge, which, with the help of centrifugal force, will help the melt to properly distribute inside the mold, completely filling it.

How to improve the quality of the product?

In fact, for real a quality item cannot be obtained at home without fine-tuning.

You can also improve the quality and appearance by making shape with fusible material... To do this, they first make a plaster cast from the model, according to which our part will be made, this cast should consist of two parts, which are fastened to each other. Paraffin or wax melted in boiling water is poured into the formed cavity, and after it has solidified, the plaster shell is removed.

Next, the resulting low-melting model is placed in a special casting mass, forming holes for draining the paraffin and pouring molten bronze. After that, the foundry mass is placed in boiling water, the paraffin melts, and it is easily poured out of the mold.

The resulting casting mold is smoother and produces better quality products than a conventional mold.

The following video shows the process of melting bronze at home.