Features of zippers

A zipper is a useful thing that has firmly entered our life. Many do not even think about its features, but every day they use this invention, putting on clothes or shoes. Although zippers are similar in design, they differ in size, shape, and function.

general description

The zipper is much more comfortable than buttons or buttons, so it comes as no surprise that it is used to equip different types of clothing, shoes, bags, professional or travel equipment. This is usually a functional lock, but sometimes such details can be decorative.

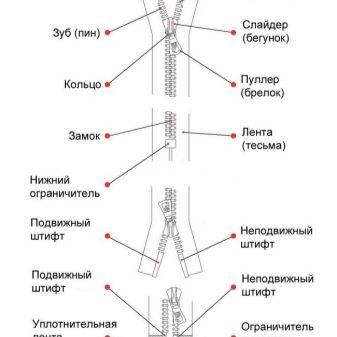

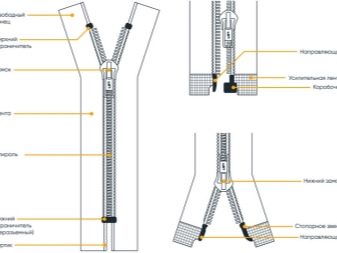

The design looks quite simple: the product consists of two belts, most often textile ones, on which the teeth are fixed. They can be metal or plastic. The connection of these elements is carried out using a movable lock - it is usually called a "slider" or "dog". Suitcases and backpacks, as well as outerwear, jackets and work equipment, often have two sliders for easier and faster access.

A zipper is sometimes called a "snake", although in fact these are different types of fasteners. The second one is simpler, it has no teeth, and the connection occurs by pressing one profile guide into another. A clasp like this is not very strong and will not withstand serious tearing force. With this in mind, it is used to make zip bags and stationery envelopes, and sometimes for cheap wallets.

The cost of zippers is relatively low, which is why many budget brands use them. However, a poor-quality fastener can quickly fail, and often this means that the owner will not be able to use the thing until the fittings are replaced.In some cases, it is possible to fix the zipper if the breakage is not serious, for example, the tongue of the lock flew off, or the teeth are slightly bent. But there are also situations when the fastener will have to be changed completely, in which case the repair will be more expensive.

To eliminate the likelihood of a quick breakdown, it is advisable to carefully handle things, do not pull or pull the lock too hard, and also pay attention to the quality of the fittings when buying:

- the color of the tape should be uniform, without spots, stripes and other visible defects;

- it is definitely worth checking the sliding of the slider, it is important that it moves easily, does not get stuck;

- the teeth must be strong and securely attached to the tape.

Usually companies that produce quality products and care about their reputation carefully select accessories for their products, so you can rely on well-known brands.

If you purchase zippers separately, for repair or sewing, you should also choose trusted manufacturers.

History

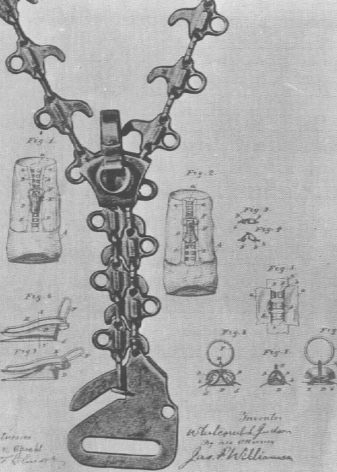

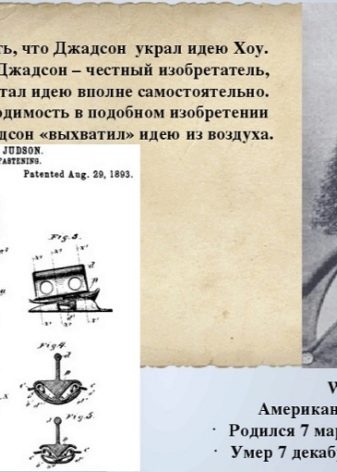

Fastening a zipper is a matter of a couple of seconds, but it did not come into use right away. This invention has come a long way before becoming a part of our everyday life. It all started in 1851 when Elijah Howe came up with his "automatic continuous clasp". However, she did not gain popularity, since the inventor himself did not consider it to be something important, worthy of advertising and widespread distribution. Instead, he chose to focus on sewing machines. Lightning was remembered again after 20 years. It is not for nothing that they say that some ideas are in the air, since the idea of such a castle came to mind already to another inventor named Whitcomb Judson. He wanted to help his friend who was injured in the fire. Due to a back injury, the man found it difficult to lace up his shoes, and he asked Judson to come up with some kind of fastener that would help make it easier.

The inventor not only fulfilled the request of a friend, but also went further - he patented his idea. In 1891 it was registered as a "shoe fastener". It was the prototype of the modern zipper - there were hooks on one side and loops on the other, and they were connected with a tongue wrench.

Judson was even able to attract investors and convince them that the new fasteners will be successful. However, hopes were not justified, people simply did not understand how to use such a product, despite the fact that instructions were attached to it. In addition, production turned out to be too expensive - the cost of producing the fasteners alone exceeded the cost of a shoe or a bag. The inventor tried to improve the design of the lightning, but still turned out to be close to bankruptcy.

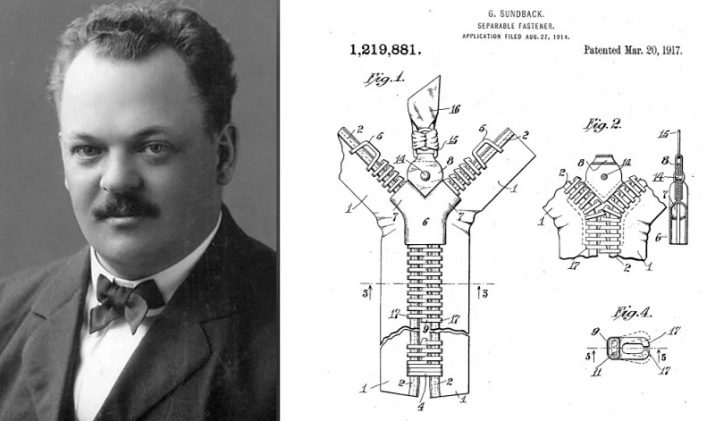

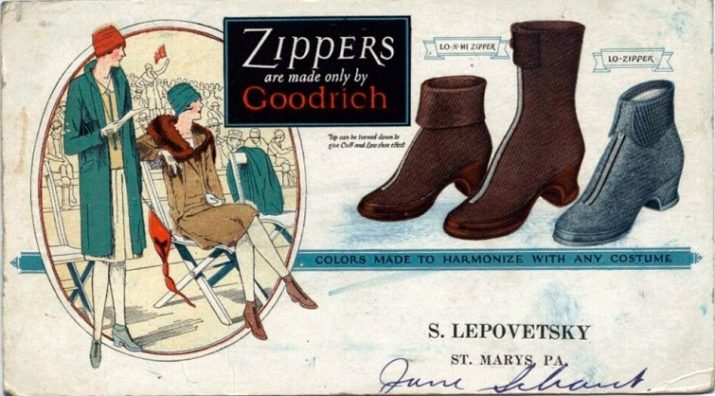

The situation changed in 1905 when a young engineer, Gideon Sundback, joined the company. He worked hard and almost completely reworked the original idea. The new fastener had more teeth, which were held together by a spring, but most importantly, its production was much cheaper. However, it turned out that the structure was not very reliable, so further improvements were required to make it stronger. Success came in 1917, when they began to equip uniforms for the military with lightning. The soldiers appreciated the convenience during the service, and after returning home, many of them purchased clothes and shoes with a new convenient lock.

Other citizens followed their example, so gradually the invention finally received its recognition. However, this lock was only used when sewing men's clothing. In the society of that time, it was believed that a zipper that quickly unfastens is inappropriate on women's clothing, as it hints at the availability of a woman. But in 1930, thanks to the fashion house Madame Chaparel, the situation changed, the trend was quickly picked up by other famous fashion designers. Models with zippers became available for women, and a little later, comfortable fasteners appeared on children's clothes.

Views

Modern manufacturers have significantly expanded the range of locks. On sale you can find fittings made of different materials, with one or two runners, detachable and one-piece types of zippers. There are also reinforced options with additional protection. The length is different - from 5-10 cm to 80 cm and more, in this case the products are delivered in roll packing. For convenience, several classifications of fasteners can be used.

By design

Most often there are three types of products.

- Twisted or spiral. They are made of synthetic fiber, which has a specific shape, which is the reason for the name. The spiral is wound on the braid or sewn to it, while the protrusions are stacked so that they alternately connect to each other when fastening.

- Tractor. The teeth are attached to the braid and are located separately, they are usually plastic. The clasp is a bit like a tractor caterpillar in its shape. Such accessories are most often used when sewing outerwear. Thanks to its design, the zipper is easy to move and practically does not jam.

- Metallic. The teeth are made of brass or nickel, and the shape of the fastener is somewhat reminiscent of a tractor. Thick wire is used as a workpiece. These products are the most durable, but can sometimes gall if the teeth deform over time.

Each variety has its own characteristics. Twisted fasteners are lightweight, but do not withstand mechanical stress. Tractor - more durable, but inferior to metal. Steel products are reliable, but they have the largest weight of all.

With this in mind, it makes sense to select fittings for a specific task so that the parts can withstand the operating conditions.

By the presence of protection

The design may include an additional retainer. According to this principle, fasteners are divided into three types.

- With auto-lock. Inside the slider there are special spikes with springs that come out of the hitch with the teeth if you pull on the lock tab.

- With a mechanical lock. The spikes are located on the tongue, they connect to the zipper if you lower this element down.

- No fixation. A regular slider that can move freely in different directions.

Protection is necessary to prevent accidental opening of the zipper. Typically, such accessories are used when sewing workwear or in the manufacture of camping equipment.

By material of teeth

The prongs are usually made of plastic or metal. Each material has its own advantages and disadvantages.

- The plastic zipper is lightweight, does not freeze in the cold, and has a smooth ride. With such a fastener, there is less risk of accidentally pinching the skin, therefore, children's clothing is often supplied with such accessories. However, the strength of the plastic is not very high.

- Metal zippers are considered more reliable and difficult to damage. Such products are capable of withstanding serious loads. The prongs can bend, but they do not break and can be returned to their original position. The disadvantage of metal is its weight.

Other

Lightning can be classified by connection type.

- Non-detachable. They have stops at the top and bottom, the two sides cannot be completely separated from each other. Such fasteners can be seen on cases and bags, pockets. They form an opening through which the owner gains access to the interior.

Fastening can be on one side, for example, like the fastener of pants - two parts of the zipper are connected only at the bottom, and on top they diverge when unbuttoned.

- Detachable. They can be seen on jackets and other outerwear. It unfastens completely, while the two parts of the lock are freely separated. Such a design provides for stoppers only in the upper part, and at the bottom there is a pin that is inserted into the slider if it is necessary to fasten the zipper.

Top manufacturers

Japan takes the lead in the ratings, it is in this country that about 50% of the total world volume is produced. Especially popular YKK brand... And also among the leaders Swiss brand RIRI.

It is worth paying attention to the Spanish and Italian brands: Raccagni and Lampo... Among domestic manufacturers are in demand Molniya-SPB, Omega-plus, Alyzip, Orekhovskaya Manufactory.