All about reinforced threads

Reinforced threads today can most often be found in those areas of the garment industry where the manufacturer places the highest demands on the finished product, its resistance to wear and tear. They are also used when sewing at home. The article will discuss the features of reinforced threads.

What it is?

Reinforcement in the generally accepted sense is all sorts of ways to strengthen a particular material by combining its properties with the much more durable and wear-resistant properties of another material. It is the increased quality characteristics of the latter that will be able in this case to be transferred to the first material, thereby improving its own excellent properties.

Most often, certain products are required to be as strong as possible, to be in operation for as long as possible, and to have a low wear threshold. And this already obliges a company that produces different materials to use the most reliable seams. In order to achieve such indicators with minimal costs, the sewing industry must use threads that will have a high degree of strength - reinforced threads. They are just perfect for creating stitching or closing seams on any modern piece of fabric of almost any thickness.

Their increased tensile strength, in addition, also allows you to get the most smooth and very even seams.

Properties

Such a plan is almost impossible to simply break the threads with an effort. They will also resist friction and have excellent resistance. Reinforced sewing threads are actively used both in production and in everyday life. With their help, you can easily get really very strong seams that will have a long service life.

The properties of the threads for the raw materials used.

Polyester yarns

This is one of the most common types of reinforced sewing products. The main positive aspects of such threads:

-

among the huge variety of products, you can find threads of varying degrees of strength;

-

they will have an increased level of wear resistance;

-

the structure of the fiber will be characterized by high stability, which means that there will be no shrinkage of this fiber;

-

if the finished product is accidentally deformed during washing or use, it can be quite easily brought back to its original shape;

-

heat resistance, which is also extremely important for the manufacture of certain types of products, for example, uniforms for employees of the Ministry of Emergencies;

-

manufacturing of products gives a minimum amount of waste, which, by the way, is further transformed into secondary raw materials.

This kind of thread is most often the primary basis for the production of thin and knitted fabrics, various ropes or cords, as well as ribbons.

Polyamide yarns

They are characterized by much greater strength. However, such threads also have their negative sides, for example, they are characterized by increased electrification. And also one of the most significant disadvantages is that these threads can turn yellow from ultraviolet radiation and quickly lose their elasticity. In order to prevent this kind of negative effects, special stabilizers are attached to such threads in production.

Polyamide threads are most often used to create braids, durable fabrics for various upholstery or floor coverings, for the production of women's stockings and socks.

Microfilament threads

They managed to combine the best characteristics of polyamide and polyester threads. Perfect for the production of all kinds of home textiles, elastic forms for sports, fabrics for special purposes.

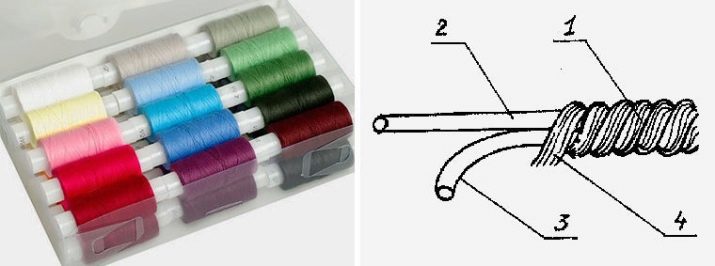

Views

There are 3 types of reinforced sewing threads. They differ from each other in the type of fiber used to braid the polyester complex core. In order to know exactly which of the types of threads is in front of you, you need to turn your attention to 2 letters that will be indicated on the working spool. The first of these letters is always "L". It will be the same for all threads and will denote the base of the thread core - that is, in this case, complex polyester fibers with low shrinkage. The second letter will denote the name of the braiding material itself.

1. Marking of two letters "LL" will mean that the outer part of the sewing thread used is staple polyester fiber, which is also called lavsan. This variety is called the most versatile, since it guarantees an increased strength of connection of all available sewing elements. And in addition, it will provide an excellent appearance of the seam and its elasticity characteristics. Most often, such a composition is used in order to overcast cuts, much less often - for finishing stitches.

Fibers with a lavsan braid are 100% synthetic components. The main characteristics of the material are that the threads are highly resistant to alkalis, various solvents, and acids. They have an antifungal effect and will actively prevent harmful microorganisms from appearing on their surface. The melting point of such a material will be about 260 degrees. The composition can be ironed without problems with a hot iron, but the degree of its heating should not exceed 150 degrees. An extremely curious fact, lavsan reinforced threads can be safely washed in hot water. The degree of their shrinkage will be completely insignificant (no more than 1.5%).

LL-threads are quite often used for sewing blouses, knitwear, coats and workwear, leather goods and denim.With their help, they produce shoes, covers for furniture and cars, items for equipping tourists.

2. In the designation "LS" the second letter denotes the siblon.

3. Marking "LH" meansthat as a winding, cotton threads of a fine-staple type are used here. They are not as strong and wear-resistant as LL, but at the same time they are distinguished by the ability to easily withstand temperatures up to almost 200 degrees.

Cotton braided threads are most often composed of 33% cotton and 67% polyester. They have the following quality characteristics - they are characterized by increased resistance to various solvents, alkalis, they begin to melt only at a temperature of 260 degrees. But the iron for ironing them can be warmed up to 200 degrees. But there are also significant drawbacks to these materials - when washing, reinforced cotton threads will lose to lavsan products. Moreover, they sit down much more (from 2 to 2.5%).

LH is considered simply irreplaceable in the production of bobbin lace, in high-quality stitching of elements from leather or leatherette, in the production of seat belts and flour bags, and they are also actively used in weaving carpets.

For to obtain a high-quality seam, the threads should be selected taking into account the density of the material being sewn. For example, 45 LL are suitable for dense fabrics for suits and coats, and 40 LL are suitable for light fabrics and medium-weight products, as well as knitted fabrics.

What are they used for?

Reinforced threads are suitable for all types of products, they create strong fastening, closing seams. The thickness of the fabric or other material does not matter. High tensile strength, wear resistance also guarantees the creation of smooth seams that meet all requirements.

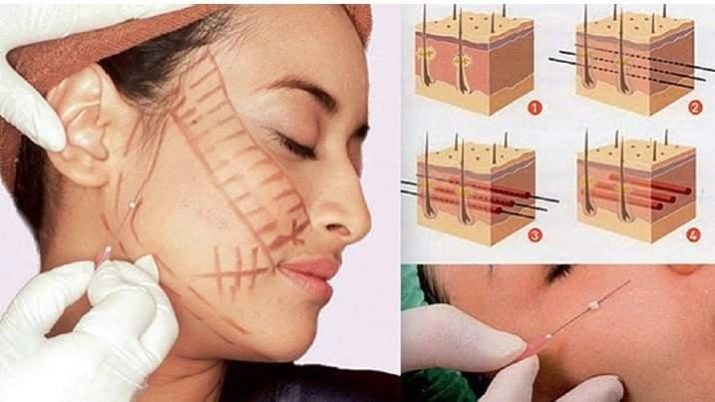

Reinforced yarns are suitable for the production of high tenacity fabrics. Sometimes threads are added when lifting a face, creating reinforced nets in vegetable gardens.

The fabrics that are created from such threads will hardly differ in appearance from various natural materials, but in terms of quality characteristics they will seriously surpass them.

They have the ability to withstand significant loads, and will not lose their original appearance under any impact. In the modern world, you can easily purchase both such threads and fabrics made from them. Blankets are also made of threads, and beautiful artificial fur is produced. The production of various clothes from reinforced yarns has also proved to be excellent. Products are able to withstand a large number of washings, have high elasticity properties, do not shrink during washing, and are very pleasant to the touch.

The porous composition of this kind of tissue will "separate" the sweat drops and significantly increase the rate of their evaporation. "Breathable" fibers will perfectly protect from any bad weather, will not get wet and will not be blown out. The fabric of these threads is often used to create thermal underwear, special suits for sports activities.

The high elongation of the reinforced yarns makes it possible to process various elastic fabrics with them. They can be used to neatly overcast the edges of certain fabrics, and can be used to work on an overlock.

Reinforced yarn fabrics do not require serious maintenance. They are resistant to fire and high humidity. It is for this reason that they have proven themselves so well in the automotive and electrical engineering industries.

Very cool ... didn't know the difference.