What are nylon threads and how are they used?

Thread is an amazing thin twisted product required in the sewing industry, it is obtained from fibers on special equipment of weaving factories. The properties of the threads depend on the material, the number of twists, the direction of the twist, thickness and density. The article will talk about nylon threads.

general description

Textile threads are natural, synthetic and combined, they are made from various raw materials. They are classified into single twist and double twist yarns. They also distinguish between left-sided - S, right-sided - Z and the combined direction of twisting. The thickness is measured in tex - this is the linear density, that is, the mass of one kilometer of thread in grams, which means that the higher the value in tex, the thicker the thread. For cotton threads, the thickness is indicated by numbers 10, 20, 30, 40, 50, the larger number corresponds to the thinner thread. For silk threads numbers - 18, 33, 65; lavsan designate - 22L, 33L, 55L. For nylon threads, the marking is 9K, 50K, and the thick thread has a higher number.

Distinguish between polyester (lavsan), polyamide (nylon) and combined synthetic threads. All of these fibers are high strength, elastic and abrasion resistant.

Capron has other names, namely: polyamide, nylon. In 1938, the famous German chemist Paul Schlack synthesized it from oil refined products. Already in 1943, the first plant for the production of nylon fiber, which was used for sewing parachutes, began to work. Development was also carried out in Russia, the first enterprise for the production of polyamide fiber began work in 1948. The new product quickly and firmly entered production.

Capron is used in various industries: clothing, food, fishing, mechanical engineering, as well as in medicine.

Polyamide is obtained from phenols, benzenes, toluenes, which are products of oil and coal refining. During chemical treatment, phenol is converted to the monomer caprolactam. Then, as a result of polymerization, that is, gluing molecules into a long chain, a nylon resin is obtained. It is melted to 270-280 ° C and extruded through metal molds with tiny holes. The resin jets are drawn out and cooled with air. The resulting fibers are twisted into threads, at the end of production they are treated with special compounds to improve quality.

The properties of polyamide are unique:

-

strength and durability, a thread with a thickness of 0.1 mm can withstand a load weighing 0.55 kg;

-

elasticity and elasticity, when breaking (unlikely), the nylon lengthens only by 10%, and after the stress is removed it returns to its original position;

-

has antibacterial properties, is not eaten by insects;

-

nylon is resistant to mechanical damage, abrasion;

-

temperature resistance of polyamide up to 120 ° C;

-

low moisture absorption (up to 10%), this property is important for a fishing net, since a slight shrinkage of the thread occurs in the water, and the mesh nodes are securely fixed;

-

polyamide is extremely tear-resistant, its breaking length is 40-60 km (for comparison: fine-staple cotton - 36 km);

-

nylon is acid-resistant.

However, polyamide fiber has several disadvantages. When exposed to temperatures above 120 ° C, nylon decreases its strength and ability to absorb moisture. With prolonged exposure to sunlight, nylon loses its color. It also accumulates static stress, so wearing nylon underwear is uncomfortable.

Nylon thread is smooth, has a certain shine, has no roughness, breaks, does not cause allergies, retains its color during heat and damp processing. It does not "lint", has a good twist, and the lines made on a typewriter look smooth and beautiful.

Species overview

Depending on the purpose, nylon threads are divided into weaving, knitted, shoe, net-knitting.

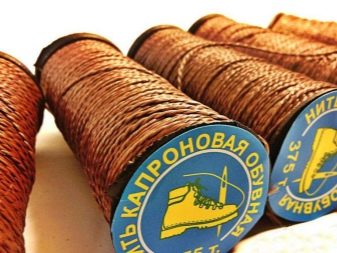

Shoe nylon thread is mainly white (unpainted) or black, less often colored. Marking is different in thickness: 29 tex, 93 tex, 187 tex, 280 tex, 375 tex. Its diameter is from 0.75-0.8 mm to 3.0 mm. The thread itself is smooth, twisted. Shoe thread is produced in various wrapping: from small spools to different sizes of bobbins, length, respectively, from 10 to 3000 meters. To enhance the water-repellent properties, the boot thread is additionally treated with wax. The color of the waxed thread is different: white, black, red.

For fishing, a nylon braided cord is made. When weaving nets intended for fishing a certain type of fish, use a cord of various diameters from 0.16 mm to 2.5 mm. Distinguish between harsh (unpainted) and dyed thread, as well as waxed, cord, which does not deteriorate in water.

To work with leather in the manufacture of bags, belts and other accessories, polyamide threads of different thicknesses are used - 187 tex, 375 tex. For hand sewing, threads with a diameter of 0.4 mm are suitable, for belts - 0.5 mm, for sewing bags and backpacks - 0.7-1.0 mm with a double twist. When sewing various types of leather on a typewriter, nylon 40 is used.

According to the structure of the fiber, sewing nylon threads are divided into smooth, textured and low-stretch ones. They are marked: 65K (0.36 mm), 95K (0.45), 140K (0.55), 190K (0.70), 300K (0.80), the larger the tex value, the thicker the thread. Smooth threads are very strong and elastic and have significant elongation up to 300%. In the sewing industry, when sewing clothes on typewriters, monofilament is used. It is so thin that it is not visible in the product.

Sewing nylon threads are used for both manual and machine stitching, they are produced on spools and bobbins.Smooth threads have proven themselves well in hosiery, lingerie and knitwear industries, as well as in work with beads. They come in a variety of colors and are colorless. Tights, underwear, sports and bathing suits are made of smooth polyamide threads.

Textured (high volume) yarns appear more voluminous. They have a pleasant shine, are more curled and stretch well. They are used in the process of making artificial fur, they are used to weave carpets, they are used in sewing leather products. The low stretch threads are soft and delicate to the touch.

They are not too elastic, therefore they are used when sewing knitwear.

Selection Tips

Depending on what the nylon thread is used for, its appropriate thickness is selected. The denser the material, the thicker the thread is selected.

For the manufacture of fishing nets, bobbins with a large number of meters are used. In the shoe and fishing industry, waxed cord thread is used, since it does not get soaked in water.

Monofilament is elastic and durable, very thin. It is used to process the edges of garments, hem the bottom of trousers and skirts. For dark fabrics, use black thread, for light fabrics - white. The size of the needle should be appropriate for the thickness of the thread.

Applications

Nylon thread is versatile, strong and durable. Its cost is low, so it is widely used in various industries. So, in aviation, parachutes are sewn with such threads, ropes and slings are made of them. In light industry, nylon thread is necessary for sewing clothes, shoes, decorative items, fabrics, hosiery are made from it. In medicine, surgical nylon threads are used. The fishing industry produces tackle. Nylon is resistant to abrasion, therefore it is widely used in needlework. It is used in work with beads, in embroidery, in the manufacture of jewelry.