Features of textured threads and their use

Few people know that textured threads can be used for sewing elastic bands, processing garments on an overlock. In addition to home use, they are actively used for industrial purposes, making special materials and fabrics.

What it is?

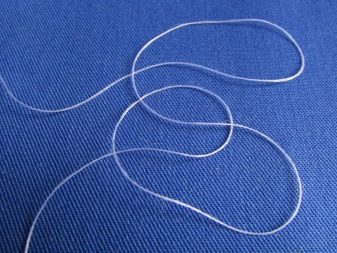

Textured threads are a twisted form of fibers, which makes them impossible to stack tightly in a complex skein. In other words, a loose structure is created, but due to the twisting, elasticity and softness of the threads is achieved, which does not affect the strength and wear resistance indicators.

Views

All types of such threads have different characteristics in terms of operation and are produced in different ways:

-

in the classic way;

-

by false torsion;

-

aerodynamically;

-

pulling the thread along the blade;

-

by the method of separating together twisted threads;

-

due to pressing by the type of corrugation.

Depending on the technology, the following types of textured threads are distinguished.

-

Highly stretchable. The name itself speaks of the properties of this type: the threads are highly stretched, increase in size by 2-3 times. Made in a classic continuous way. Sold under different names - superloft, helanka, tvasil, silastic.

-

Low stretch - this is belan, crimplen, maron, astralon. They are based on elastic, in the manufacture of such threads under thermal influence they change the structure of crimp, and they practically do not stretch.

-

Crimped. The technology of their manufacture is based on several methods, one of them is pressing in a hot chamber and heat fixation in the "accordion" state. These are such threads as kanebo, ozhilon, gofron. Another method is based on passing the thread over a hot metal blade. This is how rilon, evalon, frostyx are made.

-

Looped thread. It is produced by an aerodynamic method, as a result, the main thread is divided into smaller threads, which, intertwining with each other, form a stable structure. These are such threads as tasuran, nefafil, rodelia, aeron.

-

Mixed warp textured yarns - this is when several different types of threads are twisted into one length.

-

Bicomponent - in such a composition, fibers with different shrinkage. Some of them are stretched during the production of threads, some are shortened, as a result a crimped volumetric thread is obtained.

-

Profiled thread. Manufactured from dies with non-circular cross-section holes. Such a composition shines less, but it has better adhesion, strength and hygroscopic properties.

Speaking of the types of textured yarns, it is worth mentioning high-volume yarns. It contains low-shrinkage fiber (in the form of viscose, wool, nylon, lavsan and others) and high-shrinkage (in the form of Oxon 10, Nitron B) in a ratio of 50% to 50% or 70% to 30%.

The manufacturing technology of such threads is similar to the process of spinning cotton. Already in the skein, the yarn is heat treated with highly hot water or steam.

The result is a fluffy thread that is soft and voluminous. It, like other types, is used in sewing and weaving.

Depending on the raw material, textured yarns are divided into polyester, polyamide and microfilament. The most common ones are with a polyester composition. They are wear-resistant, durable, the fibers do not shrink and there is practically no waste from them. Polyamide threads are even more durable, but they become electrified, turn yellow over time and become inelastic.

However, if you add stabilizers to them, then this can be avoided. Such threads are used to make braids, are used in the production of socks and stockings.

The microfilament thread combines the best characteristics of the first two types described above. It is used in home textiles, sportswear, specialty fabrics, and so on. Fabrics made from such threads are outwardly difficult to distinguish from a natural base, and their quality is even higher.

What are they for?

Textured threads are used for both industrial and home sewing. Due to their increased extensibility, they process knitwear, other elastic materials, and are used for overlock.

They create durable fabrics that are resistant to water and fire. Such materials are in demand in the electrical and automotive industries. Such fabrics are used to make suits for firefighters and those who work in oil mines.

The need for textured threads is only growing, and their manufacture is improving. Fabrics made from such threads do not require special care, and the porous structure of the base distributes perspiration and increases the evaporation of moisture - which is why they are suitable for sportswear and outdoor suits.

These clothes can be washed many times, they will not deform, they will not shrink, they will remain elastic and pleasant to the touch even after prolonged use. From such materials they sew thermal underwear, breathable waterproof jackets that can perfectly protect from bad weather.

From fabrics woven on the basis of textured yarns, in addition to knitwear and textiles, carpets, sleeping accessories, and even artificial fur are produced. In a word, this is a demanded basis, and the scope of such threads is very wide.