Japanese kitchen knives: types, rules of selection and care

Japanese kitchen knives are known all over the world for their incredible beauty, increased strength, amazing sharpness and maximum ease of use. Craftsmen for the production of quality knives, which in their sharpness will not be inferior to traditional samurai swords, nowadays make almost 900 types of various kitchen tools and accessories. For this reason, before choosing the most suitable kitchen knife, you should familiarize yourself in detail with all its features and functionality.

Peculiarities

The most obvious feature of a modern Japanese cutting tool can be considered its sharpening only on one side, which allows you to very quickly cut almost transparent pieces of fish or other products that can be part of traditional oriental dishes.

To operate a knife with such a unique edge, a certain skill is required. Therefore, beginners may find it difficult to use this tool at first. Having become accustomed to using conventional double-edged models, it can be difficult for an average chef to adapt to working with such unusual products. This is precisely the skill of the professionals from Japan.

By the way, today you can easily order and purchase Japanese kitchen products for left-handers separately, since when purchasing knives for the kitchen, you will more often be offered copies with a blade that is sharpened only on the right.

The best blades are those that are made by hand, experienced craftsmen forge themselves, and then polish and sharpen the knife. Very often on this kind of models, released in Japan itself, you can see the personal signature of the gunsmith on the handle.

The main difference between these unique tools can be considered the use of the most durable metal without various components toxic to human health. For their manufacture, the purest types of steel are selected:

- steel "shirogami", better known under the name "snow-white paper";

- steel "aogami", which is popularly called "blue paper";

- Damascus steel.

Aogami is a derivative of shirogami, which differs from the latter in the presence of the smallest particles of chromium and tungsten in the alloy. This variety is considered much stronger than shirogi, but it will also be less sharp. The main difference between aogami can be considered the long-term "life" of the blade, which will retain its sharpness for a long time.

The index of sharpness of Japanese knives is called "kirenaga" - this is the designation of the time in which the blade will be in a sharpened state. The type of future slicing and the comfort of the work of the chef, who wants to get the best result, will directly depend on this state. In order to use such a knife in everyday life, these indicators will not be significant, but for a sushi chef it is impossible to imagine his professional activity without the sharpest product made from aogami material.

The blades are characterized by excellent durability and a typical wavy pattern on the product itself.

Unobtrusive recesses can be made at the top of the blade so that various products do not stick to the knife when cutting. High-quality kitchen knives are made of the strongest steel by hand, and the blade is sharpened and carefully processed at the same time. Culinary accessories from Japanese masters have a fairly solid price, which is justified by a long service life. No newfangled ceramic, glass, or electric knife can surpass the lifespan of durable knives made in Japan.

The Japanese tried very hard to make the handle of the product comfortable. For the production of this element, expensive materials are selected - micarta and chrome-plated metal. In inexpensive products, you can find handles made of special wood. Most of the European knives are distinguished by the use of inexpensive polymers, which is why the knives have a short service life due to the frequent breaking of the device in the area of contact between the blade and the plastic handle.

Views

There is a wide variety of oriental culinary knives.

- Tojiro knives used both at home and quite popular among professionals. They differ from other products in width, weight, as well as the length of the blade, strength and the number of layers of steel used. For tools made for household use, steel is selected from 1-3 metal layers, and tools for professionals have blades of 30-40 layers of steel.

For the home, it's best to choose the most affordable models - they have wooden handles, and the chefs will definitely like specimens with integral steel details.

- Usuba Products suitable for quick cutting of vegetables. They are distinguished by a thick butt, the blade has a sharp sharpened blade. On average, the weight reaches 200 g. The severity of the device at the very beginning of operation sometimes causes a feeling of discomfort, but after a little getting used to actively using the cooking tool, you can easily cut hard vegetables.

- Yanagiba Sushi Knife - an important assistant to the chef, with the help of which you can practically "jewelry" cut the fish into the thinnest pieces that will be visible. If we translate the word "yanagiba", then it will mean "willow leaf", and in fact the truth bears full resemblance to a willow leaf. The length of the blade of the product is from 25-30 cm. The razor sharpness of the product is suitable for cooking sashimi and will allow you to precisely cut the fish into pieces.

- Deba models will greatly facilitate the work of a cook with complex fish. The rounded blade has a length of approximately 16-23 cm and a huge handle for even distribution of pressure when cutting the hardest parts of various fish.

This type of product has many varieties - Kunisaki deba helps butcher crabs. A heavy product with a pointed blade is useful for cutting hard shells, they can get meat from lobster, lobster or crab.

Mioroshi deba is perfect for quick cutting of the thickest fish bones.

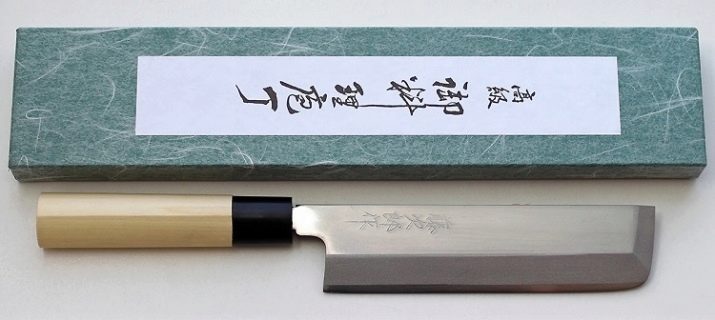

- To cut vegetables into even neat slices, it is recommended to use a Japanese mini-hatchet. Nakiri. The Nakiri has an extremely thin blade that is only 2 mm thick.

- Knife Santoku can be called one of the most versatile oriental knives. If we compare the santoku with European specimens, it most resembles a specialized chef's knife. Santoku means "3 virtues" in translation, which emphasizes its versatility. Knives are suitable for fast cutting of various products, especially if the blades are made of Damascus steel.

- Gyuto - a thin knife with a length of 18 to 30 cm, it can quickly cut meat and any fish, without making great efforts.

- Sujihiku - a slicer, originally necessary in order to pull the veins, nowadays it is perfectly used for slicing various products.

- Petty Knife (station wagon) Is a product with multipurpose functionality, it can be cut and cleaned. It stands out among other tools with a slightly raised handle and a blade with a length of 7 to 15 cm.

- Sushikiri - a traditional knife needed to cut a portion of ready-made sushi. It features a rounded blade.

- Nakiri bocho - product for cutting vegetables.

- Pankiri - a special knife for slicing bread, has a striking wavy sharpening, with its help you can cut even fresh bread without the appearance of crumbs.

- Sashimi yanagiba - it is good to make sushi or sashimi with this knife. A thin blade will perfectly cut the fillet into the same thin pieces. One of its subspecies is Fugubiki. This flexible and extremely sharp specimen is used to cut the famous poisonous puffer fish.

- Sashimi Takobiki - narrow, but long products for sashimi. Blades in the form of a rectangle, 20-32 cm long with a sharp end for working with tuna or rounded, if you want to cut an octopus.

- Unagisaki or Dojosaki - are distinguished by the presence of a sharply going to the edge of the edge and are purchased for cutting eel.

- Baran-kiri - a trapezoid product is useful for quick work with crabs.

- Ajikiri - a product with a wide, but shortened blade. Such a product is chosen for working with many types of fish. Its length is from 9 to 15 cm, its thickness is up to 4 mm.

Manufacturers rating

What companies are engaged in the production of the best Japanese chef knives?

Global

Knives have been produced under the name of this brand for more than 50 years, which are distinguished by the amazing quality of the hardness of the blades. Global manufactures its products in two versions: the Sai range is for experienced chefs and the Standard range is for household chores. The latter have a textured "polka dot" handle to prevent slipping. The company has a division of products by size - these are large "G" and small "GS", and the letter "F" informs you that this is a real forged fixture.

Kanetsugu

The best oriental swords and knives have been produced under this brand for many years. Now this dynasty of famous gunsmiths forges blades for culinary purposes, giving them the popular katana shape.

Kasumi

It produces products from rather expensive and rare metals, which endow all the produced series with a kind of "character".

- Series "MasterPrice" and series "Standard". Usually they have an unusual sharpening on both sides and comfortable handles made of wood or fabric base with coarse weaving, which are held together by polymers.

- Ceramic series. Models that are only slightly inferior in strength to diamond. They have the usual sharpening for a European on both sides and a handle made of special plastic, they are extremely demanding when leaving and must be stored as carefully as possible.

- Hammer series. Products that have a surface with a relief, which allows you to create a special pillow of air between the blade and the products prepared for cutting, which is why nothing sticks to it during processing.

- Series "Titanum"... A series of cheap knives with a high quality titanium coating, which guarantees them extra strength. Has blades of various colors.

Masahiro

The craftsmen of this brand have come up with an extremely popular steel from an alloy of molybdenum and vanadium. It was she who glorified oriental kitchen knives and brought them world fame.Masahiro products are highly appreciated in the restaurant kitchen, and the number of models entering the world market has already exceeded 3 thousand.

Hattori

Produces both kitchen and hunting knives. Has a high reputation among buyers. Each piece is subject to strict control, and if even one of the parts does not meet the high standards of the brand, it will be sent for rework. Today the company produces 3 lines of knives KD, HD and FH.

The KD series is distinguished by the highest quality of workmanship and consumer characteristics.

Kiomo

Produces multifunctional, versatile and durable knives that are resistant to any load. The most common work for a multipurpose product is to peel and cut small-sized products with pleasant ease and grace.

How to choose?

The sheer variety of Japanese knives can sometimes make the final choice difficult. You can choose the right knives by describing their detailed characteristics, usually this information is present on the product packaging. You should also be guided by the price, which will classify a certain model as the middle class, standard or premium. The subtype, weight, parameters, the number of layers of steel, the quality of wood or plastic will determine the price of Japanese instruments, which will surpass similar specimens from Europe in many respects.

Particular attention should be paid to the sets of knives, which include certain types.

- The universal device will allow you to work with different types of fillets, different fruits, hard vegetables. Convenient for everyday use, fits perfectly in the hand. It features a massive blade. Its main purpose is to cut seafood.

- An excellent chef knife will handle even large bones and any hard food from the freezer.

- A vegetable knife is only used to chop vegetables.

Care

The production of knives in Japan is equated to an art form. For this reason, Japanese craftsmen pay special attention to the correct operation of their products.

- This knife should never be cleaned in the dishwasher.

- If the product is stored together with other devices, it can negatively affect the structure of the steel.

- Cutting can only be carried out on special boards - made of polymers, wood or bamboo. Wood can slow down the process of loss of blade sharpness. A resin base that will absorb the cut is just perfect for working with a Japanese piece.

- The instructions for this product should be strictly followed. Do not use a bread (cheese) knife when cutting meat and various seafood. These attachments can be selected to work with only one type of product. That is why they have different shapes of both the blade and the handle.

- It is worth storing such knives in a special wooden stand that will absorb moisture. Moisture adversely affects the condition of the steel. can also be stored on a railing with a magnet, where the likelihood of scratching the blade will be minimized.

- For greater safety, after using the knife, it is better to put a special cover on the sharp blade.

- To maintain the sharpening angle, it is necessary to sharpen the knives only with a special sharpener.

With careful use and proper care of Japanese blades, they will not lose their amazing sharpness and chic appearance for a long time, allowing each chef to feel special ease and comfort when working with any solid products.

How the famous Japanese kitchen knives Masahiro are created, see below.