Overlockers: what are they, how to choose and set up?

Overlocks are useful devices for seamstresses that allow them to professionally process the edge of the material at home. Industrial models are even more functional, they are able to work for a long time without stopping, they are suitable for hemming carpets, carpets and paths. Modern technology for home use does not replace the sewing machine, but complements it, providing maximum comfort in use. Private business prefers versatile solutions and before choosing a carpet machine, the performance of the equipment is carefully studied.

When getting acquainted with the overlock device, the user has many questions. For example, how to set up equipment without resorting to a wizard. In fact, even a non-professional seamstress can handle this task.

Before you carry out the adjustment and the simplest repair of the overlock at home, you just need to study the instructions for it. However, most of the problems that arise during operation are quite typical for this type of device and it is not difficult to eliminate them.

What is it and what is it for?

Overlock is a type of sewing equipment capable of performing a narrow range of operations. Its main task is to process cuts of textiles of different density and thickness. Depending on the type of equipment - industrial or domestic - the productivity and complexity of the equipment in operation vary. The machine overcast and trims the edge at the same time, protecting the fabric from shedding, puffing and thread loss.Certain types of equipment can sew parts with the formation of a line in the form of a chain stitch.

Depending on the features of the overlock, it can use 2-10 threads in its work when forming seams. The first model of such a technique appeared back in 1877 and made a real revolution in the mass tailoring of textiles.

Overlocks are required to perform several operations.

- Manufacturing of flat products of a square or rectangular shape. You can get sheets, including terry, tablecloths, napkins.

- Sewing children's clothing. Diapers, undershirts, sliders for the smallest should have seams with a stitching outward. In the clothes of older children, the seams are treated with an overlock, preventing the formation of rubbed areas on the skin.

- Patchwork... Large-size patchwork is best done with an overlock.

- Securing the edges of elastic fabrics. On knitwear and stretch fabrics, the use of special equipment gives results that are unattainable with a conventional sewing machine.

The overcasting machine significantly expands the capabilities of the seamstress, makes the edge processing more beautiful and high-quality. Its acquisition is mandatory for in-line production, where you need to ensure that all products look as aesthetically pleasing as possible.

Difference from carpet locks and sewing machines

A cover-sewing machine, a sewing machine, a carpet-lock - these devices are well known to professional seamstresses. In everyday life, it is not very convenient to use all the units at once. Each of them requires setup, adjustment and installation space. A conventional sewing machine creates straight or decorative stitches from a zigzag stitch. It is designed for sewing materials in several layers, hemming, embroidery and other operations.

The sewing machines will form the lockstitch. There is no shuttle in overlocks, the threads are intertwined in a different way.

Difference with cover sewing machines

A coverstitch or cover sewing machine is device used for mass sewing of elastic, knitted fabrics. Such devices grind materials together, forming a line that does not tighten the details of the product. The flat seam is widely used for sewing T-shirts, swimwear, sportswear.

The sewing machine does not trim the edge, but uses a chain stitch as an overlocker. The cut of the product is retracted inward and does not allow the edges to shatter even with strong tension.

The main difference between a cover sewing machine and an overlock machine is the weaving of threads. If the overcasting technique connects the material only along the edge, here the stitch can be done in any part of the product. The interlacing of the looper and needle threads occurs without restriction at the place of seam creation.

Differences from carpetlocks

The carpet used when sewing - a universal device that combines the capabilities of an overlocker and a cover sewing machine. This type of technology was first patented by Pfaff, and later it began to be produced by other brands.

A coverlock is a more complex device that is considered professional equipment. It makes sense to buy it only if you have to sew knitted and stretch fabrics regularly. A coverlock will be useful to every home craftswoman.

Among the differences between the carpetlock, one can also highlight the creation of seams with an upper overlay, in which the seamy and front parts of the stitch look the same.

How do I determine the type of device?

If the shuttle and shuttleless devices are noticeably different in appearance, then it is rather difficult to recognize the overlock, carpetlock and cover-sewing machine. Of course, if you do not know about their main difference - the sleeves overhang. The overlock has the shortest because there is no need for a spacious work platform.

For a cover sewing machine, it is as long as possible, the same as for sewing equipment, since individual parts of the product are stitched. The coverlock has a medium-sized sleeve platform, versatile, suitable for various operations.

Device

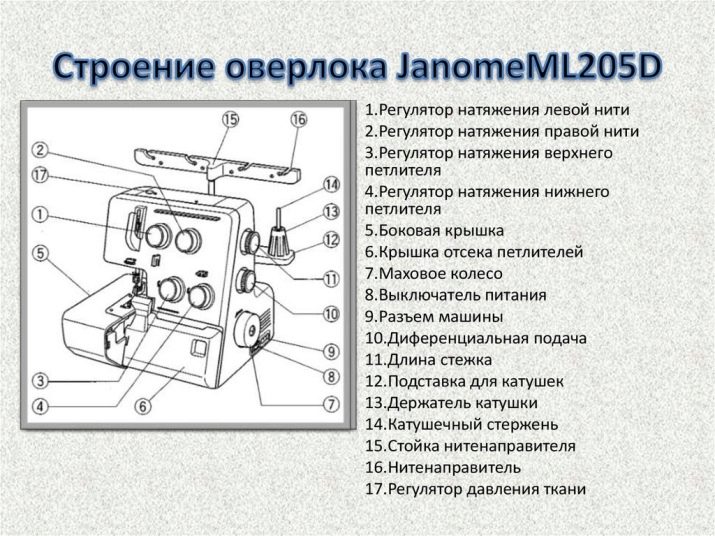

Overlocks differ in their design, but all products of this type have common features. These include the presence of the following elements.

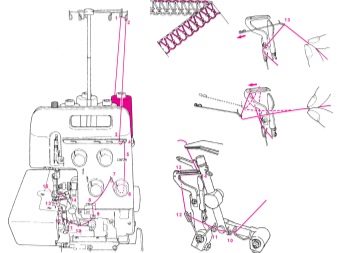

- Cutting element. A system built into the design of the machine allows for the simultaneous joining and trimming of fabric edges. The overlock has 2 knives - the upper, movable, with an adjustable position, and the lower, which always remains stationary.

- Flywheel. It can be used to manually raise and lower the needle while piercing the fabric.

- Loopers. It is they who form the stitch. They look like hook-shaped metal elements that make cyclical movements during operation. They come with a peephole and blind, according to the type of movement they are divided into rotating and swinging.

- Needles. Their number depends on the number of threads. Only 4- and 5-thread overlockers have 2 needles.

- Foot. It presses the fabric against the feed dog and throat plate. Feet, depending on the operation performed, are divided into stitching and overcasting.

- Telescopic stand. It guides the threads to the tension discs from the spools. Eliminates obfuscation.

- Thread tension adjusters. In the overlock, they are either on the front panel or hidden in the case. With manual control, the adjustment is carried out by turning the special knobs. In computer-controlled models, the desired parameters are set using the LCD display and buttons.

These are the main structural elements. In many overlocks there are additionally options in the form of a free sleeve or a regulator of stitch parameters. In addition, in household models with 3-4 threads, a detachable finger can be used to make it easier to create a stitch.

Differential feed is also not present in all types of overlocks and, if present, then as an additional structural element.

Types and their principle of operation

A household overlock is a fairly popular sewing device. Its classification is most often carried out by the number of threads used - from 2 to 5.

- Double-strand. The easiest option. For sewing in 2 threads, you need to overlap the upper looper using a special device - a convector.

- Three-thread. The most popular household overlock. Creates a seam using a spiral weave. Can be used for hemming, hemming or Flatlock seams.

- Four-thread. Can perform not only overcasting, but also other types of seams related to strengthening. These models are considered semi-professional. They can sew flat stitches, sew knitwear, strengthen weak points on products.

- Five-line. Overlock, the functionality of which is close to the professional version. It can be used to overcast and seam parts at the same time.

Industrial overlocks are larger, have up to 10 threads, and may have an additional classification. It is customary to distinguish special carpet models capable of stitching the thickest materials.

By the type of control, the models can be electromechanical or computer. By the way of threading - manual and automatic.

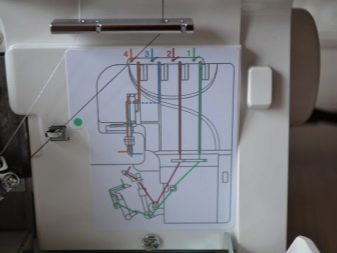

The principle of overlock operation is usually explained in terms of the most popular three-thread stitch. It is formed like this:

- a threaded needle pierces the material;

- upon reaching the bottom point, a return movement begins;

- a loop is formed above the eye of the needle with the looper;

- the lower and upper hooks each move along their own trajectory;

- with the help of a needle, the stitches are fastened, the overcasting of the edge.

With an increase in the number of threads, the complexity of the stitch chain increases, more and more elements are involved in its formation. The rest of the overlock, regardless of the design, works according to general principles.

Selection Tips

When choosing a good overlock for your home, it is important to have a clear idea of what qualities the device should have from the very beginning. Let's consider the most important parameters.

- Functionality. If you have to process the edges of small products in a small volume, you should pay attention to three-thread models designed for overcasting the edges of low and medium density fabrics. They are insensitive to the type and quality of the thread and are used with conventional spools. If you have to sew a lot and often, you need to choose more technically advanced models.

- The presence of a rolled seam. It makes the edge processing more presentable. You can use it when sewing large-sized blankets, curtains. This stitch is also used on non-hemmed skirts and trousers.

- Variable seam width. It is optimal if it has a range of up to 9 mm and allows you to take into account the peculiarities of processing the edges of different types of fabrics.

- Recommended material density. This can be important if you plan to work with denim, raincoat fabric, costume fabrics.

- The presence of a differential. It is needed if you have to sew frequently elastic stretch and knitwear.

- Built-in converter. It is necessary for sewing very thin and delicate fabrics, as it allows you to sew a two-thread stitch. In the absence of a converter, you should pay attention to the possibility of buying it separately from the device.

- Threading system. Automatic is needed mainly for continuous production. If the overlock is rarely used, this option can be neglected.

If you plan to overcast the edges of carpets and coverings similar in thickness, it is advisable to choose special machines. They are suitable for carpets, rugs, paths, prevent shedding of their edges. The carpet overlocker belongs to the category of industrial equipment, provides the highest possible speed of work, and is adapted to in-line production of works.

Popular models

The modern market offers a wide variety of overlock models. You can find budget options for beginners or professional equipment. The Prym brand, which produces needles, needle threaders, eyelets, is considered to be the best manufacturers of accessories. The most famous overlock brands are Aurora, Elna, Family, Janome, Merrylock.

Among the most relevant models are the following.

Sandeep GN1-2D

Chinese overlocker of three-thread type. The model is equipped with a 150 W motor, a thread stand, trimming knives. The overlock seam is 4 mm wide. This is one of the most controversial models in customer reviews. Positive and negative opinions about her are divided approximately equally. The advantages include fairly simple control, affordable price and compact dimensions.

Aurora 600D

One of the best models of household 3/4 strand overlockers. The technique successfully performs 8 operations, it implements an efficient looper threading system at the bottom. Raising the presser foot automatically looses the thread tension. The model supports differential feed of the fabric, allows you to smoothly adjust the pressure of the fabric.

It is a versatile overlocker that can easily overcast anything from layered denim to chiffon.

Family 244D

Japanese brand 4-thread overlocker, produced in Taiwan. It weighs 7 kg and has narrow and wide overlock seams, Flatlock, rollstitch and hem. The model provides a differential feed, adjustable presser foot pressure, LED lighting. The overlocker is versatile, reliable, and provides easy performance of 7 operations.

Elna 664 Pro

Multifunctional home overlocker recommended by professionals. The model implements the most simple threading of the lower looper with thread, there is a safety system that does not allow starting work if the working compartment of the mechanism is open.There is a table on the front panel with threading tips.

This 12-step overlocker features an inclined needle mechanism, a cut-off knife, adjustable cutting width and differential feed function. The optimal model for an experienced seamstress.

Janome MyLock 785

Household overlocker working with 2, 3 or 4 strands. The model performs 8 operations, is suitable for all types of fabric, is equipped with a built-in converter of the upper looper, differential feed of the fabric, adjustment of the presser foot, a compartment for collecting garbage. The technique develops a sewing speed of up to 1300 stitches per minute. The overlocker is made in Taiwan, but developed by a Japanese company and is well suited for home use.

Operating rules

Among the rules that must be followed when working on an overlock, it is important to highlight the following points.

- Threading. In modern professional overlocks, most often there is a needle threader that allows you to automate the process, or a diagram printed on the case. Experienced seamstresses rarely use it, since they use a technique that allows them to quickly complete the procedure. It is enough to remove the old coil and install a new one. Then cut the end of the thread already threaded and connect it with what is to be threaded, stretch and cut the knot near the eye of the needle.

- Choice of overlock seams. A narrow and wide flatlock is usually available, allowing you to sew knitwear, hem, rolled and overlock stitches in a variety of designs. It is imperative to use exactly the option that matches the type of fabric.

- Selection of a needle. Normal sewing needles are suitable for the overlock. They are selected taking into account the characteristics and thickness of threads or fabrics - usually the manufacturer indicates the optimal parameters for a particular model. In 51 class overlocks, needles with round flasks are used, in the rest - with partially sawn ones. During installation, the groove should be directed towards the operator.

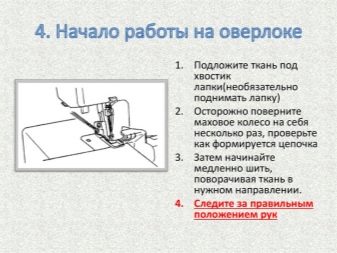

- Beginning of work. To create a stitch, place the foot along the edge of the fabric. Lower the needle and start working, keeping the direction in a straight line. When passing through pronounced corners, you need to stop overcasting at the end of the line, raising the foot to make a turn. With a small radius, the rounding is done in jerks, with a large one - it is enough just to smoothly pull the fabric.

Possible problems

The overlock can be repaired by yourself if it comes to minor malfunctions. For example, when the equipment skips stitches or makes a dull thud during operation, the problem is most often a curved needle or dullness. When viewed at the point, the place of abrasion will be clearly visible. The curvature is easily detected by removing and placing the needle on a flat, flat surface.

If there are gaps, looper problems may be the cause. Lack of thread in the needle will result in the overlocker simply not sewing. To fix the problem, you just need to thread the thread.

Other common faults include the following.

- Uneven cut of fabric, formation of a terry border... It is due to the fact that the knives are not sharp enough. It is usually sufficient to replace or sharpen only the upper cutting element. If the cutting elements are severely abraded, they will have to be completely dismantled and new ones installed.

- Installing non-standard needles... A mistake or deliberate use of unsuitable components will cause the equipment to stop sewing. Typically, standard sewing needles with a bulb flat on one side can be used for this.

- Deterioration of stitch quality, appearance of “loops”. The discrepancy between the thickness and elasticity of the threads with the tension settings leads to exactly such results.

- Parts get hot, the mechanism creaks. It is necessary to lubricate the overlock to prevent the shaft from jamming.

- The fabric does not move well across the platform. The problem is most likely due to poor pressure on the presser foot.

- The thread breaks, gets tangled. Excessive tension may be the cause. Also, the thread that has jumped off the spool can cling to the body, preventing its normal course.

It is worth considering that complex malfunctions cannot be eliminated at home. You will need to contact a specialized workshop.

Advice

The expediency of buying an overlock is an important part of deciding on the choice of this technique. He is needed by those who are professionally engaged in sewing textiles, fond of cutting and sewing. Without an overlock, you will not be able to work with knitted or very stretchy fabrics. It is important to remember that this equipment is not interchangeable with the sewing machine, and the zigzag stitch is very different from the one that overcast the edges.

You should not buy a household overlock if you have to sew 4-8 hours daily on it. Home appliances simply will not cope with the tasks set, they will overheat and will soon require replacement. It will be much easier to immediately take equipment that can withstand the most intense loads without any inconvenience.

If the plans include the implementation of various seams, including decorative ones, the technique intended for the atelier will be of little use. She is capable of performing only 1 operation. Household overlocks can easily handle 12 stitch patterns when changing settings.

Additional options help to make your work more convenient. For example, the presence of a trash compartment will help you not to be distracted by cleaning while overcasting. Using the automatic needle threader will reduce the time spent changing threads and bobbins.

How to choose an overlock, see below.