How to set up an overlock?

An overlock is a device from the category of sewing equipment that allows you to smoothly cut and process the edge of a fabric product. Complex settings and repairs of this device can only be performed by a qualified craftsman, but it is quite within the power of an ordinary user to select and adjust the thread tension correctly before starting work.

Fundamental rules

The principle of regulation does not depend on whether your overlock is Taiwanese, Japanese or Chinese, since the thread tension adjusters are located on the outside of the machine body. As a rule, there are 4 of them, according to the number of threads involved in the overwrap process. All adjusters have a tension scale from 0 to 9.

For each type of fabric, before starting work, you need to set up an overlock.

The values of the adjusters are set according to the thickness of the fabric and the type of thread being used. In most cases, overcasting can be performed at the set tension value under the number “4”.

But do not immediately start processing the product itself. First check the quality of the overcast seam on the piece of fabric and, if the process went well, you can start working.

The thread tension is regulated as follows:

- from 2 to 3 - weak tension;

- from 3 to 5 - average tensile force;

- from 5 to 7 - strong tension.

An important condition for high-quality overcasting of the material is the thickness of the thread, and it is important that all 4 threads are of the same type and thickness. Another prerequisite for obtaining an even overcasting stitch is the correct selection of the needle thickness number corresponding to the density of the fabric being processed. Typically, for each overlock in the instruction manual, the manufacturer indicates the brand of needles and their recommended numbers.

If the needle is not matched to the correct size and thickness, this can lead to a failure of the overcasting process, and in some cases even to a breakdown of the machine.

Thread tension

Each tension regulator performs its own function, they are painted in a specific color on the overlock. Their function is as follows:

- first regulator - is responsible for the thread tension of the left needle of the machine;

- second regulator - is responsible for the thread tension of the right needle;

- third regulator - tightens the thread of the upper looper;

- fourth regulator - tightens the lower looper thread.

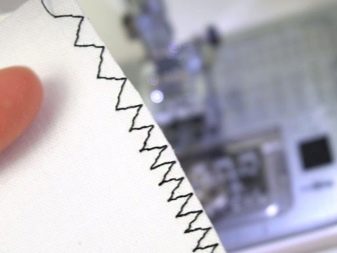

When setting up, we use a piece of tacky as a prototype and carefully examine the quality of the stitching. Inspection and necessary adjustments are made in the following sequence.

- We check the work of the left needle. If we see wrinkling on the fabric, it means that the thread tension is too great. Therefore, we decrease the indicator of the regulator by one division and again check on the fabric sample how the stitch will look like. We reduce the tension until the wrinkles on the cut being processed disappear.

- We check the evenness of the line. The left needle is also responsible for this. If we see a "ladder" of threads, then the tension needs to be slightly increased.

- As soon as we have found the desired indicator for the left needle, at which an even stitch is obtained without wrinkling the fabric and loosening the threads, then we set the same for the right overlock needle.

- Evaluating the work of the loopers. The stitching on the fabric should be even, the pattern between the stitches should be even. If you see thread loops behind the cut edge of the fabric being sewn, the looper thread tension is too weak and needs to be increased. The adjustment is carried out until the threads for which the loopers are responsible lie flat.

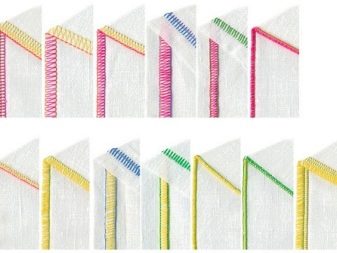

When sewing the garment, it is important to select the type of stitch that is appropriate for the thickness of the fabric. Most modern overcasting machines can sew at least 5 types of stitches.

- 4-thread overlock stitch. The process uses all 4 threads and 2 needles. This stitching provides a durable seam and can be used on knitwear and any dense textiles.

- 3-strand overlock stitch with 5mm seam width. It is carried out with the left needle and 3 threads. Suitable for medium-weight fabrics.

- 3-thread overlock stitch with 2.8 mm seam width. To be carried out with the right needle and 3 threads. It is applied on thin fabrics.

- Narrow overedging line 2 mm wide. Used on chiffon and other delicate fabrics.

- Hem stitch 2 mm wide. It is used as a decorative material for fine fabrics.

When sewing delicate fabrics, it is important not only to adjust the thread tension dials, but also to the machine presser foot. If the pressure of the foot is too strong, then no adjustment will help, and the fabric will wrinkle during sewing until this cause is eliminated.

Stitch size

To get an even stitch when processing a product, among other settings, it is important to choose the correct stitch size. For this, there is a special regulator with a scale of divisions on the machine body. The choice of the regulator value depends on the density of the fabric. The thinner the fabric to be overcast, the smaller the stitch size should be. When choosing a stitch length, do not forget to take into account the thickness of the thread.

When setting up an overlock, the following information will help you navigate:

- thin fabric (georgette, cambric, muslin) - stitch 2-3 mm, thread No. 80-90;

- medium material (broadcloth, gabardine, serge) - stitch 2.5-3.5 mm, thread No. 60-80;

- dense fabrics (tweed, jeans, jersey) - stitch 3-4 mm, thread No. 50-60.

In some cases, while sewing, you will see that the stitching has skipped stitches. The following steps will help you regulate this process:

- check the condition of the needle - is it not bent, is it installed correctly;

- take out the needle and check its number - if it does not match the type of your overlock, replace it;

- inspect if your car is properly refueledif one of the bindings is missing;

- make sure the threads are not wrapped around the stitch adjustment pin;

- evaluate the pressure of the presser foot.

After checking all the parameters, make a prototype and, after making sure that the edge overcasting machine works normally, start processing the product.

Recommendations

For a normal and long-term service of your overlock, it is necessary to carry out regular maintenance. This procedure is as follows.

- Cleaning the mechanism. This simple manipulation is performed every time after the completion of the work. It is necessary to remove dust, scraps of fabric, threads. This can be done using a hard brush with overcast movements.

- Overlock lubrication. To ensure smooth and quiet operation of the moving parts of the mechanism, the machine must be periodically lubricated with special oil. Lubrication is carried out only after a thorough cleaning has been carried out beforehand.

If serious malfunctions are found, the overlock should be repaired at service centers for technical maintenance of household appliances, and when replacing units or parts, it is important to use only original spare parts from trusted suppliers.

For more details on setting up an overlock, see the video presented.