All about pyro printers

Burning out has become widespread among people of all ages. For this type of creativity, many different devices have been created; pyro printers are considered the most modern and practical. We will talk about them in this article.

What it is?

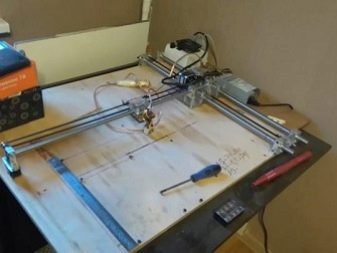

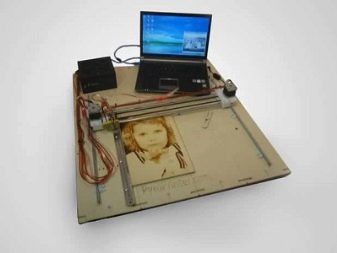

CNC burner is known as pyro printer and pyrograph. Structurally, it is a device with a numerical control module. Using an ordinary computer (including a laptop), you can easily burn pictures of the most varying degrees of complexity on it. With the help of a pyrograph, you can create real artistic masterpieces on wood, plywood, leather and even metal.

A characteristic feature of this device is the ability to control it from a computer using specialized programs. Anyone who has PC skills can use such a device. In this case, the presence of artistic ability is not required at all. The main thing is to find a suitable picture and load it into the program - the burner will do the rest.

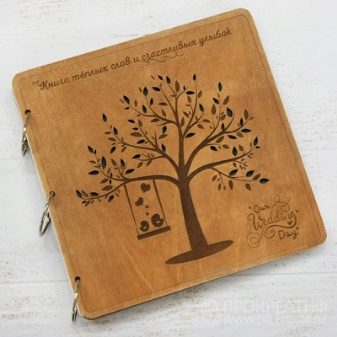

Thus, you can make a gift, a portrait, a painting or a memorable souvenir, and the image can be transferred to absolutely any surface, including cases, cases, boxes and caskets.

The principle of operation of the pyrograph is to burn the working surface of the material under the influence of elevated temperatures. As the painting is created, the work tool moves along the base and forms burn points. Their depth directly depends on the rate of movement and the exposure time: the deeper the base is burned, the darker and more contrasting the image will be.If you wish, you can actually achieve almost black prints, and if you touch the material lightly, you will get light shades.

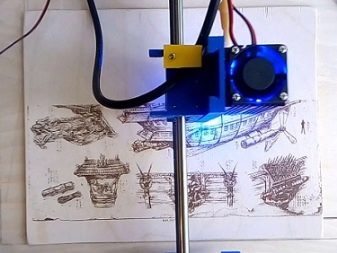

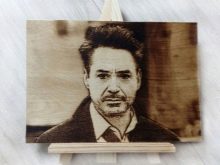

In hand-held burners, the master moves the tool on his own, therefore, practical skills and the talent of an artist are required from him. In pyroprinters, the control is fully automated. The selected photo is digitized and then entered into a special control program. Further, the device independently determines the direction of movement of the working body and the speed - this is how the picture is copied.

Description of species

There are two main options for pyroprinter designs - laser and nichrome. Let's dwell on the distinctive features of each of them.

Laser

Laser printers create a picture based on a non-contact effect. Burning out is done in separate points. Any tones and halftones in the image are formed by changing the parameters of the concentration of dots per unit of the treated area.

Nichrome

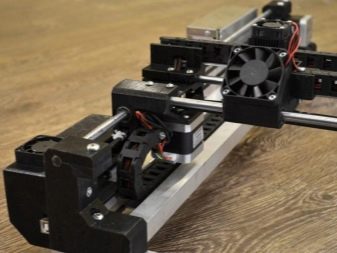

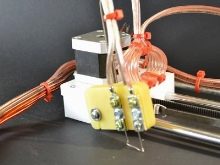

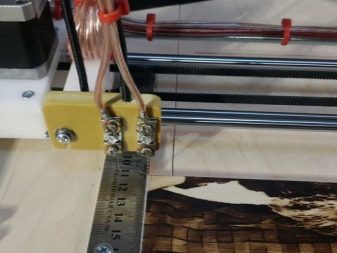

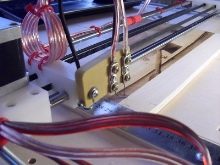

Models with nichrome thread work differently - they are in contact with the working surface. In this case, the nichrome wire is intensively heated so that the heating level is sufficient to burn through the workpiece. The nichrome thread runs directly over the surface. By smoothly moving it, you can create a solid dark stripe. The image is stuffed line by line. After drawing each line, the carriage with the wire is shifted by 0.35 mm, and proceeds to drawing the next one. The numerical parameter 0.35 mm is derived by trial and error. It is considered universal, although you can make it smaller or larger if you wish.

However, it should be borne in mind that if the distance between the lines is increased too much, there is a high risk of gaps in the picture. Line-by-line application provides an important advantage of the nichrome filament burner. The image looks like analog.

Smooth variation of the speed of the working tool provides a gradient change in tonality. That is why the picture lays down on the base like a photograph.

Top Models

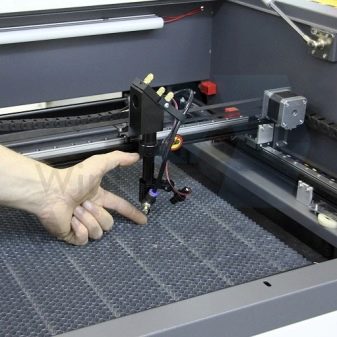

Of the laser models, the desktop was awarded the best user reviews. Zoldo 3020 KK machine. This budget model is ideal for home hobbies or small batch production of small items. Suitable for laser engraving small-format workpieces. Working area 300x200 mm. Due to its low weight and modest dimensions, the laser machine fits easily on a desk.

The device has a wide range of functions. It can be used not only as an engraver, but also as a laser cutter. At the same time, he works with any materials except metal: plywood, wood, plastic, plexiglass, leather, leatherette, cardboard, paper and even fabric. If you wish, you can even apply a picture on a natural or artificial stone, and if you use thermal tape or thermal paste in your work, you can even engrave on a stainless steel base.

That is why the machine is in demand in such areas as:

- polygraphy;

- scrapbooking;

- production of seals;

- engraving on leather goods;

- creation of souvenirs from wood and plastic;

- making magnets, badges and other miniature plywood products.

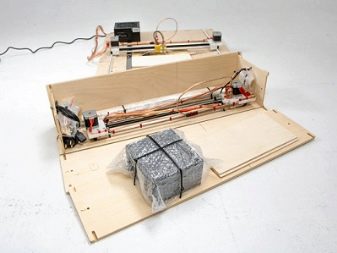

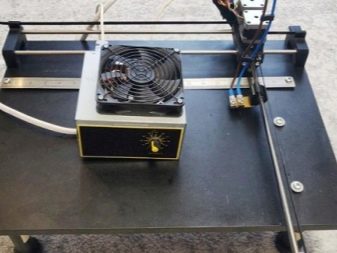

Among nichrome burners with CNC, the optimal solution from the point of view of price - quality will be PyroPrinter model. The working field of such a pyrograph is 440x420 mm, it is possible to expand the field up to 900 mm. Through the USB port, it is compatible with a personal computer, works with the operating systems Windows 7, 8, 10. The device turns on automatically before starting work and also turns off independently after the burnout is completed. It takes an average of 2 hours to create a picture in A4 format.

Burning line by line, thus shades and halftones are formed by changing the speeds. It moves along the dark elements with reduced acceleration, and processes light ones faster.Works best on wood surfaces up to 10 mm thick. With all other bases, special equipment adjustment is required.

It is equipped with a contactless sensor, which, in the event of a non-standard situation, turns off the pyroprinter - this ensures high fire safety of the device.

Selection Tips

When choosing a device, first of all, it is necessary to make a choice between laser and nichrome devices. The laser tool transmits increased accuracy of images, they are characterized by the clarity of the contours and the shape of the edges. The machine even allows drawing drawings. In this case, the thickness of the workpiece, the condition of the edges, the type of edges, as well as the degree of surface smoothness are almost irrelevant. The laser allows you to burn not only on wood, but also on glass, felt, cardboard, as well as paper, clay and veneer. The design copes with the task of applying small texts in a variety of fonts.

However, CNC laser burners have their drawbacks. Spot application does not allow achieving natural midtones and transitions on the face. When creating shadows, the concentration of black dots is reduced, and from a close distance it will be striking. Therefore, the device is ineffective when creating portraits. Low operating speed allows you to burn no more than 10 points per second. It will take 10 hours to process a 20x20 cm image.

During operation, the laser gives off a bright glow, this negatively affects the eyes. Therefore, all work must be performed with glasses selected taking into account the glow of each specific laser. When burning, tar from trees can get onto the picture. To avoid this, additional blowing is performed. But in this case, the work will be noisy, and there is no need to talk about comfortable creativity.

The laser places high demands on the preparation of the board. It is very important to tone down the intensity of the woody texture with a baking soda solution. After that, the workpiece is thoroughly washed with water and dried. However, if we are talking about plywood, then after such manipulations, it can swell at the edges. For portraits, it is better to use a nichrome burner. He will also give a better image of landscapes and still lifes. This is due to the fact that the technique provides high contrast and an abundance of halftones.

However, the device is not used to create small fonts. In addition, it will not be able to apply a picture to cardboard, paper, plastic or glass. Its only purpose is to burn on woody substrates. Another disadvantage is associated with the fact that when working indoors, it is necessary to maintain a stable temperature, it is advisable to close the windows in order to prevent a draft. At the same time, in the process of burning out, a slight odor appears, therefore, after the completion of the work, it is imperative to ventilate the room.

Inexperienced craftsmen sometimes try to use a nichrome CNC pyro-printer to work with plastic. In no case should this be done, because the resulting toxic substance is unsafe for health. Another drawback is the need to change the nichrome thread every 5-6 pictures. However, this will not greatly increase costs, since these components cost about 3-5 rubles. a piece.

Thus, the choice must be made based on the characteristics of future operation and what kind of paintings you plan to burn.

The nuances of working with the machine

In most cases, CNC burners are used to apply pictures to plywood or a wooden plate. Less commonly, the device is used to apply a picture to plastic, paper, rubber, acrylic or leather. Laser printers allow you to engrave glass and even steel. The pyroprinter is used for making document covers, decorating cutting boards, signboards of various sizes and wood business cards.However, it is very important to set up your CNC equipment before starting work.

Commissioning begins with the launch of the software. It is loaded into the computer from any third-party media - flash drive or disk. The control program is placed on the hard disk of the PC in a solid state drive or in an SD card. Before starting work, you should upload the picture you like that you plan to burn. Further, the graphic document is converted into DXF, HPGL or Gerber format. In this case, the entire programming process is visualized through the monitor - all NC commands are given in the format of G- and M-coding, which is clear for the device.

The subsequent adjustment of the CNC burner is carried out in strict accordance with the user's manual. During work, all the necessary data appears on the monitor indicating which keys should be used. If necessary, you can always make adjustments to the transferred image. The pyro printer allows you to create stylish inscriptions and pictures on the surface of various materials. If desired, even portraits and large landscapes can be transferred to the blanks.

The main thing is to load the necessary images into the computer, and the device will automatically copy it onto the surface to be treated. Of course, this kind of work does not require any artistic skills, but a sense of aesthetics will definitely come in handy.