All about epoxy for creativity

Many handicraft lovers want to learn about what transparent epoxy is for creativity, how to use it to create works. In terms of their beauty, such crafts are not inferior to products made from natural amber, and they can be made even at home. A master class on the use of decorative resin for needlework will help you learn more about working with the material.

What it is?

The epoxy resin used for creativity is a synthetic oligomeric compound, also known as a jewelry compound. The raw material has a transparent structure, rather dense and solid after hardening, and in liquid form it is fluid and viscous. This is how the decorative epoxy differs from the technical one, which has a characteristic yellowish tint.

Compositions for creativity are produced in transparent. In the color version, they are created by the master himself, adding dyes. Depending on the line, manufacturer, mixing intensity, the brightness of the pigment varies. In addition, there are special glitters - fillers that allow you to add a mixture of gloss.

Epoxy resin used for decorative purposes is produced by both Russian and foreign manufacturers. The brands Epoxy and Crystal Glass were the most trusted by consumers. Their products easily take on the desired consistency, do not spread, and form a uniform dense structure without defects. And also today, soft glass is gaining popularity - a composition based on epoxy resin, which has a pasty consistency.

It is used to sculpt decorative details to decorate glass surfaces, create original compositions and crafts reminiscent of Murano glass.

Composition and properties

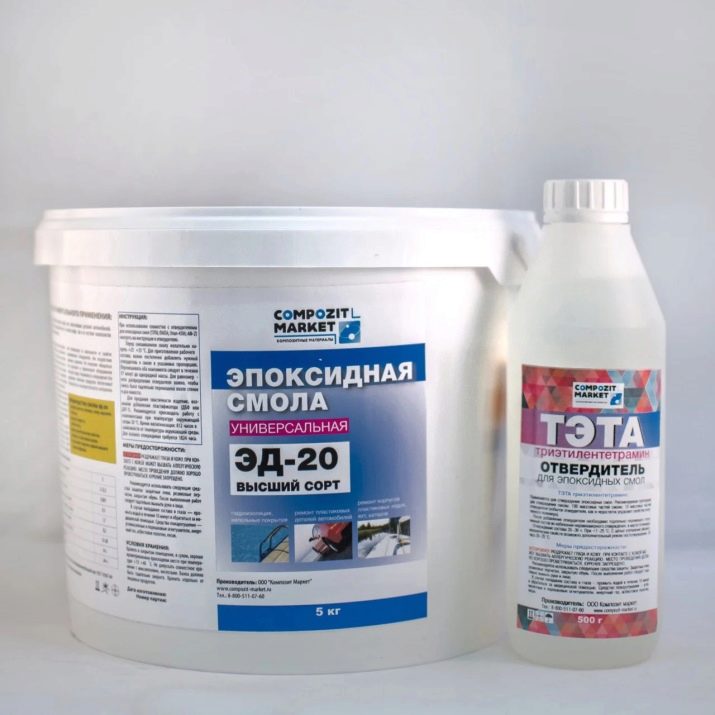

Creative epoxy comes in several varieties. Among themselves, the compositions differ in color and consistency, as well as in operational characteristics. The most popular version is marked ED-20, it is divided into products of the highest and 1 grades. The second option is considered industrial, thickens and sets after no more than 4 hours after mixing. Resin 1 grade is used for the needs of the chemical, aviation industry, shipbuilding, is used in the production of adhesives and sealants, and is used in electrical engineering.

The high-grade variety is ideal for decorative purposes. Such epoxy resin ED-20 is very transparent, viscous, easy to use, and products made from it are decorative. When a hardener is added, the correct mixture is obtained without bubbles, holds the desired shape well. Other similar compounds are used in jewelry and crafts: ED-16, ED-22.

Among the characteristic features that are inherent in epoxy resin after crystallization, several of its properties can be noted.

- High adhesion capacity to various types of surfaces. It binds well to ceramics, metal, glass, interacts with polymers, concrete, wood.

- Dielectric properties. The resin has an extremely low electrical conductivity and can be used for the manufacture of decorative lamps.

- Resistance to external influences. The hardened compound tolerates mechanical processing well, is moisture resistant, is not afraid of temperature extremes and contact with chemicals.

- Ecological cleanliness. The material is absolutely non-toxic both when creating crafts and after complete hardening.

These properties have made epoxy popular in the jewelry and decorative industries. It is used to make decorations, household items, and cast countertops and sinks for plumbing.

The composition of all types of epoxy is the same. It contains 3 main ingredients:

- caustic soda;

- diphenylolpropane;

- epichlorohydrin.

Depending on the type of compound, the proportions of the substances change. Besides, manufacturers add additives and substances to the composition that improve the artistic properties, simplify the work with the material. In addition to the base itself, to obtain a workable resin, a hardener is needed - a substance that turns a liquid and viscous composition into a monolithic one. It is he who is responsible for the crystallization process, usually attached to the selected compound, but sometimes it can be purchased separately.

Several types and grades of formulations are considered suitable.

- Telalit-590. A hardener focused on the creation of bulky products and structures. Suitable for work in rooms with a temperature range of + 20 ... 25 ° C. In a liquid state, it is completely non-viscous, resembles water in fluidity, very transparent.

- Epilox H 10-34. A technical option used in the manufacture of compositions for pouring large surfaces - with its help, self-leveling floors, countertops are created. The degree of transparency is high, the viscosity of the hardener is close to that of oil. The optimum operating temperature is considered to be + 15 ° C.

- PEPA. A budget formulation suitable for use at room temperature. No special conditions are required for hardening, the average time for full hardening is 24 hours. The composition has a light chemical smell, it is better to work with it with gloves. The color is slightly yellow, there is turbidity, the hardener is rather viscous, not suitable for creating bulky products.

In order for the epoxy resin for creativity to have an optimal consistency and other indicators, plasticizers are added to it, which provide improved strength or elasticity of the material, increasing its hydrophobic properties. Most often these are products labeled DBP, DEG-1, S-7106. If low-grade raw materials are used for creativity, the use of additives will help improve its performance. In a special compound for creativity, they are already present in the required volume.

With prolonged storage, epoxy resin for creativity, like its industrial counterparts, becomes more viscous. Solvents help to eliminate the problem; white spirit is usually enough for this. However, it is worth using such aggressive liquids only as a last resort - they are intended for technical needs, require extremely careful handling. You can remove traces of resin from your hands with acetone-containing cosmetic liquids.

To increase the decorative properties of a product, in addition to glitters and dyes, other substances or fractions are often used. Among the fillers used most often, several options can be distinguished.

- Minerals and rocks crushed into crumbs. Pomegranate, serpentine, marble, travertine look interesting. Even regular fine gravel can be used.

- Cement (artificial stone). It is added to strengthen the material or to obtain interesting decorative effects.

- Quartz sand. It is not epoxy soluble. It is used both in the manufacture of large-format floors and countertops, and in the creation of small decorative items.

- Wood flour, wood chips or bark. Gives density and strength, very small fractions are used in furniture production in the manufacture of a special composite.

- Aluminum powder. It gives an interesting visual effect. It goes well with industrial style items.

- Natural dyes. Powdered graphite is added to make the resin black. Titanium dioxide is used to obtain a pure white color.

It is not a good idea to add high hygroscopic aggregates to the epoxy resin. These include all types of mineral powders, from tooth powder to talcum powder. They also help to make the material white, but make it more fragile and vulnerable to external threats.

Applications

Creative Epoxy is a unique material that leaves incredible scope for handicrafts. With its help, art products and objects with practical application are created. Some areas of application of the material deserve special attention.

Decorations

The transparent resin is ideal for creating original handicrafts. Modern craftsmen create original pendants, pendants, brooches and rings, earrings and bracelets from epoxy resin. Products look especially exquisite, inside of which parts of wildlife are carefully preserved.

Moss, lichens, flowers, stones and other elements, frozen in a transparent drop of resin, retain their beauty for many years.

Decor elements

An unusual paperweight for papers, a stylish candlestick, just a piece of furniture that differs in shape and color from any existing things. With the help of epoxy resin, you can create design masterpieces that amaze the imagination. Their fragile beauty looks very unusual, eye-catching. Crafted flower vases can recreate the splash of sea foam or convey the fragility of frost on frosty glass.

Light fixtures

Due to its dielectric properties, epoxy resin often becomes the basis for the creation of original luminaires. The shape of the product can be any, as well as the decorative design. You can create a unique piece of furniture for a specific design project of a house or apartment.

Furniture

Using epoxy to make furniture doesn't look too avant-garde; you just have to see the result of such work. Most often, a tabletop is made of a transparent material.... When pouring into it, you can place almost any decor - from dried flowers and greenery to sea pebbles. The combination of wood and epoxy resin looks very interesting, the furniture is durable and original.In addition to countertops, beautiful and durable window sills, unusual aprons for the kitchen are obtained from this material.

Dishes

Epoxy cannot seriously replace glass or ceramics in the manufacture of dishes. But interesting decorative items are obtained from it: vases for fruits and sweets, stands, napkin holders, serving items. Tinted epoxy will work well with wood and wicker frames.

How to use?

A master class on the use of epoxy resin for creativity allows you to get a complete picture of how exactly you need to work with this material. First of all, you should follow the standard safety measures: wear rubber gloves and a mask or respirator, ensure a free flow of air into the room, cover the workplace with polyethylene or oilcloth, make sure that the air temperature does not exceed + 25 ° C.

Preparation of epoxy resin requires the purchase of a certain set of consumables:

- compound and hardener;

- disposable medical syringes or measuring cups with millimeter divisions;

- a wooden spatula for mixing the composition;

- clean containers of different sizes.

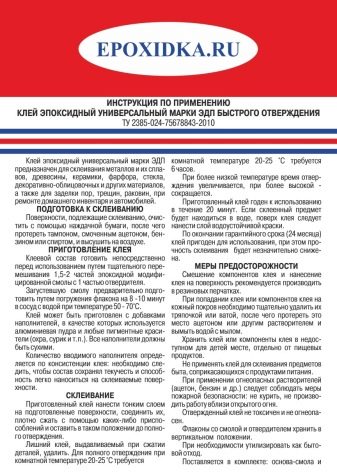

Before starting work, it is recommended to read the instructions supplied by the manufacturer to the consumables. The proportions for different formulations vary, there is no single recipe. Next, the components are combined in a small bowl or cup, cuvette. Precision proportions will be ensured by using graduated cups or syringes. Do not prepare too much resin at once, it may start curing earlier than it is used up.

The combined hardener and compound are gently and thoroughly mixed in the selected container. At this stage, glitters and pigments can be added to them. For some time, you need to perform circular movements, removing air bubbles, achieving uniformity of the composition. If they nevertheless formed, the mixture is defended and heated. The air chambers will rise and be accessible for removal.

It usually takes 20-24 hours for the epoxy to cure completely. It is important to maintain the correct room temperature during this time. To speed up the process, you can send the workpiece to the oven for 20 minutes at a temperature of + 80 ° C, and then leave it at room temperature until it completely crystallizes.

Pouring into molds

The finished resin can be applied in a variety of ways. Most often, it is cast in silicone molds - molds, giving the desired shape. Such blanks are used to make small items. Due to the peculiarities of silicone molds, the hardened resin easily leaves them. There are ready-made solutions for rings, key rings, pendants.

When using decorative natural elements - shells, stones, they are washed and degreased, herbs, moss, flowers are carefully dried. Then these components are put into a mold and filled with resin. The procedure may vary.

- With preliminary placement of decor. In this case, the decor is placed on the bottom of the mold. Then the resin is prepared - it needs to stand for at least 30 minutes. At the end of this process, the epoxy base is poured into a mold. All that remains is to wait until the workpiece hardens and clean up its uneven edges with abrasive tools - a file, a small file.

- With resin pouring. After filling out the form, the decor is distributed in it with a toothpick. This allows you to create products with symmetrical and more complex filling.

After hardening, the resin product can be subjected to additional grinding and machining. Most often, sandpaper is sufficient, but you can use abrasive nail files for manicure and pedicure. A lot of dust is generated during sanding - it is worth protecting the eyes, nose and mouth.

Casting within the framework

Epoxy resin products can be made not only in molds. There are special metal frames and frames. Their main difference lies in the need to grind the finished jewelry from the front and back sides. The lower edge of the frame is usually placed on the surface of the adhesive tape during pouring to prevent the resin from flowing out from below. You can also add decorative elements to the frame - leaves and flowers of plants, small ornamental stones, a photograph.

You can do such basics yourself. The frames are woven from wire, made of polymer clay. It is important that the shape allows the resin to be retained as much as possible within the contour.

Beautiful examples of work

The imagination of authors creating their products from epoxy is limitless. You can verify this by looking at the photo gallery.

- A triumph of nature in perfect sphere form. Natural materials have a special beauty, and even when placed in unpainted resin, they look very impressive.

- Exquisite pendants with golden metal figurines inside. The product looks elegant, not too pretentious, suitable for everyday wear.

- Original colored rings filled with transparent crystals and metal. The craft looks impressive, it may well replace traditional jewelry for a couple at a wedding.

How to make a pendant-sphere with a flower from epoxy resin, see the video.

Very informative article, thank you!