Molds and molds for epoxy resin

Making original epoxy products is incredibly fun and requires creativity. This material can be used to make amazing designer gizmos, souvenirs and fashionable jewelry. You can get the finished product only after the mass has solidified.

Given the fluidity of the mass before it solidifies, certain forms are needed to work with epoxy, that is, molds.

What are they for?

Epoxy resin is a viscous fluid substance, when added to which a special hardener, it will begin to solidify. Typically, molds are used when working with epoxy. In translation, this name means the concept of "imprint". Jewelry resin is a sticky substance that adheres to most base materials. The viscous substance does not stick only to certain surfaces, such as rubber, plasticine, gypsum, plexiglass, as well as polyethylene and polypropylene.

Silicone is considered the most convenient material to work with. Such molds have smooth walls, which makes it easy to remove already frozen jewelry from the mold. At the same time, at the end of the work, the products require only minor grinding. Molds for epoxy resin are often chosen for making jewelry or souvenirs. For pouring flat surfaces in the form of a table or floors, they are not used, in this case pouring is carried out into the formwork.

Craftsmen who professionally make original epoxy resin jewelry usually have various forms... Considering that making them on their own reduces the cost, many people prefer to make them on their own, especially if a lot of products are produced.

Molds are also used for casting garden figurines, souvenirs or shatterproof toys. For the manufacture of such crafts you can use a do-it-yourself mass consisting of silicone sealant and starch... Inexperienced craftsmen may encounter difficulties when choosing a material. It is advisable to purchase a two-component composition, this will allow the work to be carried out within an hour, which is quite enough even taking into account the adjustment.

For work, use starch, sealant and acrylic paint. This mass solidifies very quickly. The time to create a craft is about 30 minutes. The resulting mass is pleasant to the touch, velvety. If it is necessary to increase the time for the hardening of crafts, it is advisable to use glycerin or fatty cream.

Views

The silicone molds required for working with epoxy can be divided into types.

- Manufactured products, i.e. molds made in production... Such models can be called universal. In the event that food-grade silicone was used in the production, such products are suitable for the preparation of confectionery. In addition, molds can be used in soap making, candle making, and in the production of unique jewelry.

- DIY products. For their manufacture, choose either silicone or sculptural plasticine.

This material has gained great popularity due to its qualities.... It can be used at different temperatures and is non-corrosive to metals. It can be used in rooms with high humidity. Silicone can be called an ideal material for working with epoxy. Food grade and non-food grade silicone have identical physical properties. To make molds you need two-component mixture... The two-component silicone will provide the finished product with a glossy, even surface.

Often, for the sake of economy, inexperienced craftsmen purchase instead of the silicone itself sealant based on it... Mixing it with gypsum allows you to get a homogeneous mass that can harden and maintain the desired shape. Considering that gypsum has a fine-grained structure, it will not be possible to achieve a perfectly flat, glossy surface when pouring a mold. When added to the gypsum-containing form of an eoskid, you will get a workpiece that requires enhanced polishing. When choosing a silicone sealant, finished products will require additional sanding to give them a glossy finish.

Tin based

The use of tin-based molding silicone is a tough material for flexible shape. When choosing a soft tin-based silicone, it should be borne in mind that it is not used for casting molds used in cooking, as it is a non-food component. Tin-based materials are suitable for non-food purposes. They are more often used in the manufacture of jewelry and original costume jewelry. Tin-based nonfood moldable silicone has certain advantages.

- Reusable. As a result, elastic and sufficiently strong molds are obtained, which reduces the cost of creating new forms. They are very durable, so they are used more than once.

- This composition hardens very quickly.... This can be said about some brands that allow the mass to dry within a few hours. This 2-component composition is chosen only for pouring and not for coating. It is recommended to choose it for medium to large shapes. You can use its large complex molds, while it is better to use it when making a composite mold of 2-3 parts.

- An important factor is a low degree of shrinkage, not exceeding 1%... From such a non-shrinking composition on tin, copies of parts made of plastic or polymer are obtained. It can be plastic spare parts for a car, furniture items, plumbing accessories.

A sample should be taken before pouring such material.It is generally recommended to add more catalyst than conventional 2-component silicone.

Platinum based

A two-component platinum-based silicone is used for embedding the epoxy resin. The material is used in the production of countertops, facade decorative elements, window sills, facing tiles, accessories, as well as during restoration work. Due to the fact that such molds do not emit alcohols and moisture, the surface of the casting will not become cloudy and will not lose its gloss. Unlike the previous version, they have a longer service life, while they are resistant to aggressive environments.

Material features:

- non-toxic;

- has no smell;

- has resistance to alkalis;

- he has high elasticity;

- high tear resistance;

- good fluidity;

- does not shrink.

Such material will keep its shape and size in a stable state for a long time, which increases the service life of the finished form.

How to do it?

When making your own molds for epoxy, it is important to choose a base to which the epoxy will not stick. The use of such materials will ensure rapid removal of parts from the mold. You can choose ready-made molds, for example, take molds for ice or for chocolate. You can also purchase the item from a specialist store.

An alternative option would be purchase of molds in online storesby ordering them from companies that sell the accessories necessary for working with epoxy. Often, such companies are engaged in the manufacture of their own molds. Many craftsmen recommend making models with their own hands. In order to independently build silicone molds for epoxy resin, you need to prepare the necessary materials and tools.

The master will need:

- 2-component mixture;

- syringes for dosing;

- scales;

- plasticine;

- plastic containers;

- wooden stirring stick.

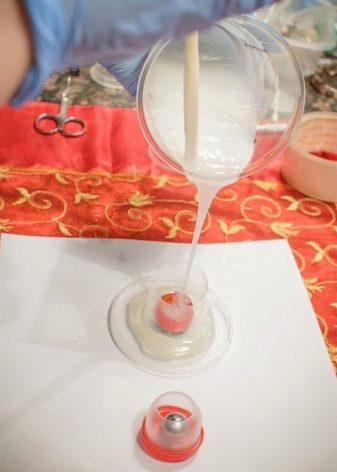

Almost all the materials you need can be found at home. If something is missing, they can be purchased. Before starting work, tools and materials are laid out on the surface so that they are within accessible limits. This will allow you to carry out work without distraction. Liquid silicone is made in accordance with the attached instructions. To do this, add a hardener to the mass in a certain proportion and then mix it thoroughly with a wooden stick.

Stir the mass very carefully, trying to avoid the appearance of bubbles. Sometimes masters recommend using a mixer, but in this case, the appearance of a large number of bubbles will be inevitable. After the mass has mixed, it is recommended to place the container in a vacuum chamber to release air bubbles. Many neglect this action, which is wrong. Silicone without bubbles will fill the mold denser. Placement in a vacuum chamber will help to deal with the problem of bubbles that have appeared.

Beginners can try making a trial mold. This will allow you to assess how effective the components are, so that adjustments can be made if necessary. For example, the finished form may not lag well with the walls. In this case, it is better to cover the walls with a special compound in the form of ordinary wax. It is easy to work with such material, while it does not require any specific conditions. Such a substance will solidify under normal conditions at a temperature of +18 to 25 degrees. After solidification, the volume of the form will not change, it will be exactly the same as when pouring.

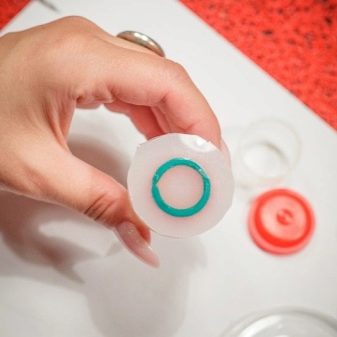

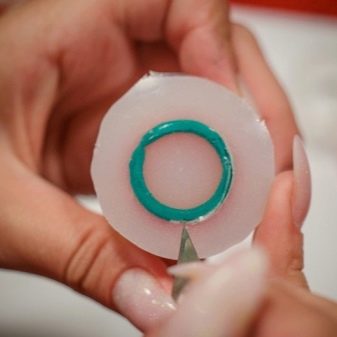

Given that the components are the same color, it is difficult to know how well the mixture is mixed. To solve this problem experts recommend tint the bulk with a dye. This must be done before mixing the two components. When making blanks from plasticine, you need to apply a layer of it on a very flat surface. Next, the part that was chosen as the base-cliché is embedded in plasticine to a depth of 6 cm.After that, silicone is poured into the container thus obtained. Now you just need to wait for the material to harden.

Silicone jewelry can be made regardless of the season. But, if you use a material that was in a cold room, it must be left in a warm room for several hours before heating. The temperature range in the room should not exceed the permissible limits.

Care Tips

Since molds can be used more than once, you need to know how to properly care for such products.

- Before starting work, the molds should be washed with warm soapy water and dried.

- Since such shapes can be easily scratched, do not pry the product with a knife or scissors, that is, do not use sharp objects.

- Small branches and dried flowers can also damage the molds, so they should be handled carefully.

- During storage, molds should not be deformed.

- It is recommended to store silicone molds in closed bags with a zip fastener. This will protect products from dust, debris and other contaminants.

Following these simple rules will allow the molds to last longer.

How to make a silicone mold for epoxy resin, see the video below.