Epoxy and wood products

Since its inception, epoxy has, without any exaggeration, changed the world. This material is at the same time very durable, beautiful, transparent and moisture resistant, it is inexpensive, and you can work with it even at home. Epoxy resin combines with other materials, such as wood, and protects its "partner" from decay. Competently made crafts based on epoxy resin look exclusive, but they are very expensive, therefore, having filled your hand, you can make great money on your hobby.

Peculiarities

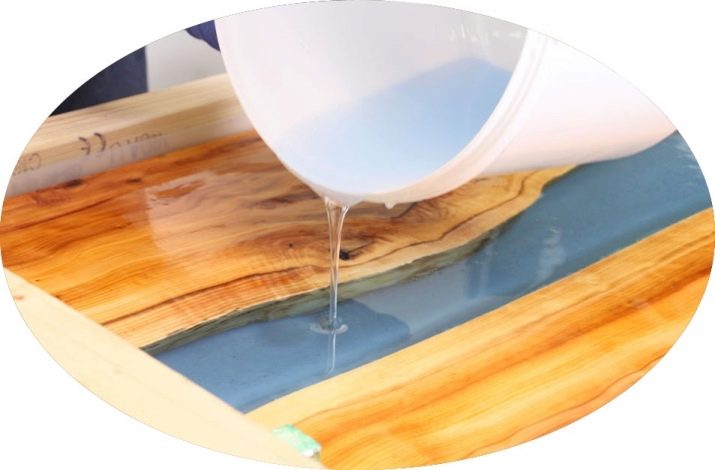

Epoxy resin is a purely synthetic compound substance in liquid form. Undiluted, it can be stored for a very long time, therefore, before pouring into molds, it is mixed with another liquid - a hardener - in the proportion indicated on the package. Only such mixing gives a start to the polymerization processes, which means that the mixed mass must be given the desired shape as soon as possible.

Epoxy resin products are used in a wide variety of industries, including even electronics and aviation., but in combination with wood, this material is, of course, the most practical for the hand-made production of home furniture or souvenirs and small utensils.

Epoxy resin combined with wood is good because initially it has a fluid form and is able to fill any cracks and chips, leveling the unevenness of the wood, especially under the influence of the laws of physics. After hardening, its surface lends itself well to grinding and polishing, you can grind grooves or drill holes in it.In this case, the material can be purchased in a certain color or completely transparent, and the latter can be tinted with commercially available dyes.

Due to the absence of shrinkage from the side of the epoxy resin, there is no doubt that the resulting product will delight the owners for a long time.

How and what are they made of?

Before getting started, you need to understand how to choose the right materials. As a rule, wood can be poured with any epoxy resin with equal success, regardless of brand and country of manufacture. In this case, a distinction should be made between the actual resin and epoxy glue - the latter already has a hardener in its composition, it is noticeably thicker, it is convenient to work with it only for gluing tightly adjacent parts, but not for filling forms.

On sale you can find both already colored resin, and completely transparent, "glass". In most cases, the master wants the beauty of the wood to be noticeable, to emphasize the overall aestheticism of the product, therefore transparent masses are in higher demand. Nevertheless, this is not an axiom, because a lot depends on the peculiarities of the author's creative idea - for example, if a huge "crack" is conceived between two halves of the tabletop, then it can be purposefully filled with epoxy of an emphasized thick color. Do not forget that The craft must be completely covered with resin, because only the core will still be colored, while the outer layer that envelops the tree will remain transparent.

As for the wood itself, it is also suitable for almost any kind, as long as its surface causes at least some aesthetic impressions. Very often, for the manufacture of crafts, those pieces of wood are used that, it would seem, are no longer suitable for anywhere - except perhaps in the firebox. A saw cut or slab is an excellent basis for a future countertop, and it is not even so important that the circle turns out to be imperfect or cracked, because resin will be used to correct the deficiency.

In the process of processing a workpiece, one must remember that wood is a priori not a homogeneous material, and epoxy, with all its superpowers, still cannot fill absolutely all spaces in the wood mass. If there is little air left in the cut, due to temperature changes during the curing of the epoxy layer, bubbles can form in it, released by the contracting and expanding core. To avoid this, it is necessary to perform temperature stabilization of wood, ensuring the same conditions for at least 2-3 hours. Experienced craftsmen do not recommend doing work outdoors, since there is a higher risk of temperature changes. If you have no alternative, then at least work in the afternoon, when the heat is no longer peak, but it does not fall quickly either. Please note that in a thin layer of epoxy filling, bubbles are always less likely - even when formed, they have time to break into the atmosphere.

If the epoxy layer on top of the wood is intended to be thick, then it is better to break the pouring into two or more stages so that the bubbles do not freeze in the thickness of the resin.

If the wood itself does not create the impression of a solid frame, you can impregnate its entire thickness with epoxy. In this case, they do exactly the opposite - they heat the work surface so that the tree expands and its pores open as much as possible. Due to heating, the resin also becomes more fluid and more easily penetrates into the smallest crevices. Only after the impregnated block has dried can it be covered with a finishing layer, but after the impregnation is completed, the temperature will have to be controlled again, keeping it at a relatively low level.

Despite all the precautions the appearance of air bubbles is still possible, especially if the master is a beginner in this matter. A common mistake in this situation is trying to warm up the workpiece so that the resin “melts” and releases air, but this should not be done, otherwise the heated wood can produce even more bubbles. If the bubbles are small, it is best to carefully pierce them with a thin needle until the epoxy hardens completely. An alternative method is to spray the resin surface with alcohol from a spray bottle, but then there is a risk of ruining the craft, because the resin can lose transparency or change color in the sprayed area. If the voids turned out to be rather large, then after the epoxy resin has completely solidified, they must be drilled out, cleaned, degreased and refilled.

Craft options

The beauty of epoxy is that with its help, you can do almost anything - there would be a fantasy, as well as the ability and desire to work... It makes no sense to consider in detail each craft in the master class version - the general principles of pouring wood with epoxy have already been considered above. Moreover, you probably will not have such a piece of wood as in someone else's example, and you do not need to adjust it to someone else's sample, but create your own, unique one.

As such, we'll focus more on those ideas that can be usefully put into practice with epoxy wood and wood.

Furniture

The most popular and well-known typically masculine epoxy resin and wood product is table top. For example, a round cut of a tree is ideal for it - even if the roundness is imperfect, and a deep crack on one side restricts the use of the table from all sides, then epoxy resin is just designed to neutralize all these shortcomings and make the product perfectly round. This approach turns a supposedly useless piece of wood into an expensive designer piece of furniture.

By the same logic, countertops are made from two (or more) separate pieces of wood. The fragments do not even try to fit to each other along the edge - on the contrary, an expressive gap is left between them, filled with a bright resin of a non-woody, contrasting color. Such a seam will hold the table securely enough so that it does not fall apart under the payload, and a thin layer of transparent epoxy over the entire surface of the product will protect the wooden core from decay.

Having mastered the production of worktops of any shape from wood and epoxy, you can begin to make facades for the kitchen. The manufacturing scheme is the same, just the final "slab" will turn out to be much larger. As a rule, it is made from several slices of wood, made in height, which makes the structure look like it was made from rough and extremely rough boards. In this option, you can make only one apron above the work surface, or a full-fledged cladding of an entire wall.

Jewelry and souvenirs

It is not necessary to make only those items that are a priori expensive from epoxy resin and wood - if you know how and love to work with your hands, you can make pleasant souvenirs for friends and loved ones.

The simplest example is an ordinary keychain. If you read above how to make a tabletop from the indicated materials, then there will be no problems with the keychain either - in fact, you are doing everything the same, only on a greatly reduced scale! What will be more, wood or epoxy, and what proportion between them will be - it's up to you. A keychain, unlike a tabletop, does not have to be a perfect rectangle - it is quite possible for it to carefully grind off the corners by rounding the product in all planes. The resulting craft can be used in another way - you can thread a chain into it and wear the jewelry as a pendant.

Some craftsmen also make pens with their own hands - why not, this is no worse keepsake than a pendant.A thin wooden tube is taken as a base, which can be carved from a small twig. The rod must be protected from the ingress of epoxy resin inside it, and then pour the entire workpiece with a fluid mass, wait for hardening and grind.

It is not necessary to strictly adhere to the shape of a typical pen, on the contrary - imagine how colorful it looks when a person writes with an object that looks much like a poorly processed piece of wood.

Other

As with any other crafts, the simplest technique for making a cutting board is to take a piece of wood that is approximately suitable in shape and size and simply fill its grooves, cracks and chips with epoxy... A feature of the material is that it is toxic to humans only in liquid form, while after the completion of polymerization, it stops emitting any dangerous vapors... This means that cutting meat, fish, vegetables and other products on such a cutting board will not pose a risk to the health of the household, but another beautiful and stylish household item will appear in the kitchen.

In recent years, a fairly common craft from the materials in question has become vase with characteristic cracks in the thickness of the wood... It looks especially impressive due to the fact that the process of its manufacture, at first glance, seems very complicated - it seems that a container was carved out of a cracked tree without breaking it completely, and then the cracks were carefully poured. In fact, the craftsmen do it much easier - they take a solid pine log, for which cracking is quite typical during drying, and immediately fill the cracks with resin.

The latter has such a high adhesion ability that a vase is drilled out of such a poly-component workpiece, and it does not fall apart from this.

Beautiful examples

Epoxy resin can be considered a genius invention of mankind, if only because it allows any piece of wood to be considered as potentially useful, which means that it greatly reduces the amount of woodworking waste.

- Take a look at this countertop: the right wooden fragment is not good for anything at all, and from the left one perhaps a seat for a small bench could be made, and even then only theoretically. Together, connected by a field of epoxy resin, they form an original and stylish table that will cost the buyer a lot.

- For the manufacture of keychain a piece of wood is needed a much smaller size, because here the tree is used purely for beauty. It combines perfectly with high transparency epoxy, which, against the background of its companion, seems literally luminous and thus bewitches. The example shows rectangular products, but it is not difficult to bring them to the shape of a pendant.

- With vases they usually tinker the most, because a priori they have to be beautiful. For example, LEDs can be built into the thickness of epoxy resin, and the epoxy itself can be poured so that color swirls are noticeable in its thickness, as in the example. Thanks to this, the craft will surprisingly combine the features of classicism and futurism, and it will definitely not go unnoticed. The problem of such a vase may turn out to be different - against its background almost any bouquet that will be put into it will fade.

For information on what products can be made from epoxy resin and wood, see the next video.