All about jewelry resin

Products made of epoxy resin look extraordinarily beautiful, even bewitching. Many jewelers choose this unique material for their work. You can make original jewelry yourself. Once solidified, the resin looks like a beautiful crystal or glass. Epoxy jewelry looks very original, stylish and elegant.

What it is?

Epoxy resin is used in construction, during installation. And also the material is used when casting jewelry, decorative items. It is a two-component compound consisting of a hardener and resin. The hardener is used to polymerize the models. Without this component, the resin will remain fluid, it is he who gives the resin the desired properties.

The resin without the second component, that is, the hardener, has not found practical use. The two-component composition, when cured, gives a unique material that is resistant to negative influences.

It hardens in a short time. The peculiarity of the polymer is that after its crystallization, it does not deform, while the surface of the product remains transparent. These qualities make it possible to use it to work with jewelry. The obtained properties are important for the manufacture of jewelry.

Jewelry made of resin has certain properties.

- High resistance to UV rays.

- They tolerate moisture well. You can swim in such jewelry, wet them.

- Bijouterie is neutral to household chemicals.

- In case of accidental falling of jewelry or impact, they remain intact, without the appearance of cracks and chips.

- They have good heat resistance.

Jewelry resin is normally yellowish due to the presence of all kinds of impurities, although the substance itself will be transparent. Usually jewelers work with highly refined material that does not have a yellow tint.

Outwardly, the hardened jewelry resin looks like glass. Products made from it are light, since the resulting material is 2 times lighter than glass.

Jewelry resin is one of the types of epoxy resin, it is less toxic than conventional epoxy, therefore, when working with it, special protective equipment is not required.

Areas of use

Epoxy resin is used in various fields. It is used for gluing, sealing, as well as in working with jewelry.

Using the material, many craftsmen create unique jewelry that amazes with its unusual beauty. The resin is used alone or applied to a specific substrate.

With the independent use of this substance, the master will need special molds. You can buy them in specialized stores for needlework and creativity.

Until solidification, the jewelry resin remains plastic, so at this moment you can slightly modify the jewelry. Until the material has hardened, various fillers are added to the mass in the form of a dye, crumb or cork.

Decorations look very impressive, inside of which insects, twigs, leaves or graceful flowers are frozen. Such things in themselves are rather fragile and cannot survive for a long time without changes. But when frozen, they will retain their original beauty for a long time.

This material is used not only to create original jewelry. Another area of application is making home decorations. Jewelry resin is used to decorate lamps, vases, mirrors, photo frames, countertops.

A countertop or other surface filled with resin, inside which various objects are placed, for example, flower petals, leaves or something else, looks very unusual.

Considering that such work is done by hand, it is quite difficult, so an experienced craftsman can make such a masterpiece. Each such product can be called a work of art.

You can buy resin for work in specialized stores for creativity, building materials supermarkets or goods intended for repair. The price of the material is low, especially since you can choose raw materials from domestic manufacturers. Such a product is usually cheaper than foreign counterparts, while being of good quality. Foreign brands are more expensive, but at the same time they have additional accessories in the form of gloves, cups and mixing sticks. The kit can also include molds, that is, special forms required for filling the substance.

It is better to opt for good material by choosing a product of a proven brand, otherwise there is a chance of purchasing lower-quality raw materials, which will fade or become cloudy over time.

Features of work

The most popular area of application for epoxy resin is in jewelry making.

For work, the master will need special molds, that is, casting molds. Usually they use silicone ones - they are very convenient, because you can easily, effortlessly remove the finished model from them.

When working with resin, it is important to observe the temperature regime. Heat is generated during polymerization. Overheating of more than 60 degrees should not be allowed, otherwise the material will be damaged.

Preparation

When working with such material, preparatory work should be carried out. The master needs to prepare a small table or tray, that is, choose an even place. It is best if the coating is glossy and the resin does not stick to the surface. Experts do not recommend using plastic bags, as resin droplets adhere tightly to them.

The tray can be pasted over with tape, or a cardboard sheet or ceramic tiles can be laid out on the table surface.

After preparing the workplace, they begin to select the necessary devices, fittings and the necessary decor are prepared. Resin with a hardener is used as materials. These components are often sold as a kit. In addition, you need to take:

- 2 syringes - you need syringes without needles for work;

- mixing container - a regular disposable glass is suitable for this;

- a stick made of wood - it is needed to mix the mass;

- mini drill and attachments to it;

- turning head.

In addition, a sieve, as well as petroleum jelly or vegetable oil and tweezers, will come in handy. You also need to take care of personal protective equipment.

Taking into account the type of decoration, fittings are selected in the form of a base, connecting rings, frames, ear wires or connectors. It is advisable to choose high-quality products, otherwise the fastener or fastener will quickly break down and become unusable.

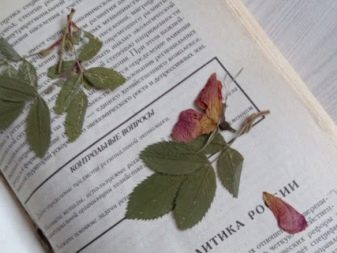

As a decoration, you can use a variety of materials in the form of dry leaves, dried flowers, as well as beads, sequins, glitter or rhinestones. When choosing natural materials, they should be dried. Since they dry for a long time, it is better to do this first. Leaves or flat flowers can be dried between the leaves of a book, and flower buds can be hung on a string in the form of a flower garland and dried in a dark place, for example, in a closet. Drying time is 3 or 4 weeks.

When working with resin, it is important to familiarize yourself with the instructions attached to the material in advance. Usually it indicates in what proportions to use the components, as well as at what temperature the work is carried out in the room. Most often it is about 25-30 degrees Celsius with a humidity of 55%.

Usually, large quantities of resin are not required to create jewelry, so excessive heating during polymerization does not occur.

Many manufacturers recommend warming up the resin by placing the tube in a container of water heated to 60 degrees. After 8-10 minutes, the tube is taken out, then the mass is mixed with the hardener.

Work on the manufacture of products is carried out in a certain way:

- resin and hardener are collected in separate prepared syringes without needles;

- the required amount of epoxy is poured into a disposable glass;

- adding a hardener, mix the mass for 3 minutes;

- stir the mass not very actively, otherwise bubbles may appear.

Often, after mixing, bubbles still remain. To maintain transparency, the mixture is set aside for 10 minutes before they float. The bubbles are then removed with a needle. In consistency, such a mass outwardly resembles thick honey.

While the mass has not thickened, fillers can be added at this stage. Sawdust or shavings and other components are used as fillers. The work is carried out carefully, taking into account the fact that they will quickly go down. When adding a filler, take into account that the fragility of the finished product depends on its amount. Usually the mass does not exceed 50%.

Fill

A sieve must be used for pouring. In the event that fillers are used in the composition, a sieve is not needed.

If the forms were prepared from improvised means and materials, you need to grease them with petroleum jelly, mastic or oil... Silicone molds or molds made of plexiglass do not need to be lubricated.

Jewelry resin is poured into the selected form, while its depth should not be more than 3 cm. After about 1 hour, the slurry will begin to thicken.

Add decor if necessary using tweezers. Do not make the layer very thick, otherwise it will harden longer. If decorative elements of a large size are used, you need to pour in half the mass, add decor, then add the remaining mixture.

When drying the model, it is better to cover it from dust. Drying time is 24 hours.

Polishing

To give the products their final look, they need to be polished. This is done using a mini-drill with special emery attachments. When turning a facet product, it must be held perpendicular to the tool.

After turning, the edges are varnished.And also the edges can be greased with diluted resin.

After completing the polishing process, small holes are drilled, which will serve as a place for fastening, fasteners. It is preferable that the drill has a diameter of less than 0.5 mm.

Precautionary measures

When working with the material, the master must observe precautions. It is necessary to prepare protective equipment in the form of a respirator, goggles, gloves and an apron.

- The room must be well ventilated. In case of insufficient ventilation, the master will breathe in vapors, which can negatively affect health.

- If the resin or hardener gets on the skin, they should be washed immediately with soapy water, then washed off again with warm water.

- In the process of work, you should wear a respirator so that particles of the substance do not enter the respiratory organs.

- It is not recommended to use epoxy on items that will come into contact with food.

Some brands of epoxy have a chemical, unpleasant odor that makes handling difficult. You can purchase more expensive brands of this material that have a less pronounced odor.

Examples of products

Products of incredible beauty are made from epoxy. They look fantastic, striking with grace and originality.

- Noteworthy are the original pendants, earrings, bracelets and rings, made not only by experienced craftsmen, but also by beginners.

- Products made in an unusual shape look extraordinarily impressive.

- Models made of epoxy resin embody the flight of design imagination.

For information on how to make a resin pendant, see the next video.