Making a cage for a parrot with your own hands

The parrot is a bird of tropical origin. Distinctive features - motley plumage color, lively disposition and the ability to imitate human speech. This genus of birds is marked by a large number of subspecies.

Used as an ornamental pet in most regions of the world. For commercial purposes, it is bred and kept on specialized farms of an industrial and private nature.

Specific requirements are imposed on the characteristics of the feed and the conditions for keeping exotic poultry at home. As a home for a parrot and a means of isolating it from the environment, it is used lattice cage. This device allows you to provide appropriate conditions for a comfortable life, while maintaining the ability to communicate with the outside world, as captive parrots are extremely social.

There are various modifications of cages for a parrot, differing in the presence of certain functionalities. Some copies may cost up to $ 1,000. Along with them, the zoo market is supplied with budget models available for the average buyer. In addition, following the instructions, you can design a cage with your own hands, which will take into account the individual characteristics of a particular bird and save money.

Requirements

The main criteria for the quality of a cage for a parrot - size, material and construction.

The physiology of any bird is a set of biological characteristics that necessitate the absence of restrictions on freedom of movement. Some properties of their body indicate dependence on constant physical activity.The size of the cell is calculated taking into account this fact.

Parrots are representatives of the genus of birds that are extremely sensitive to external factors. They easily succumb to diseases, it is difficult to survive molt and periods of physiological craving for reproduction. Along with this, one can note their exactingness to the materials from which the cage is made. Their environmental friendliness and safety are important.

The physical condition of the parrot directly depends on the design features of the dwelling. Some cages are designed with add-ons to enable the bird to meet its energy needs and gain access to water and food. These additions include:

- swing;

- rotating wheels;

- hanging hoops;

- various toys and more.

The form and materials from which additional devices are made must also comply with environmental and safety standards.

There are various modifications of parrot cages that you can assemble with your own hands at home. Before assembly, you need to prepare the appropriate materials and tools.

Tools and materials

The list of materials directly depends on certain types of cell construction. Their differences from each other are reduced to the difference in the configuration of the case. Among the common types of cells are:

- lattice with an all-metal body;

- cellular all-metal;

- lattice combined;

- combined cell;

- plastic, wooden.

The all-metal body is a structure assembled from a metal mesh with a square cell or lattice sheets, connected to each other by means of spot welding or other fastening materials.

The combo version of the case combines a wooden or plastic frame holding a lattice or mesh material on it. In this case, the mesh can be made of plastic, and the bars of the lattice - of wood.

The optimal variant of the cage design is a combined one. Its features allow you to assemble the device without unnecessary material costs using a minimum set of tools.

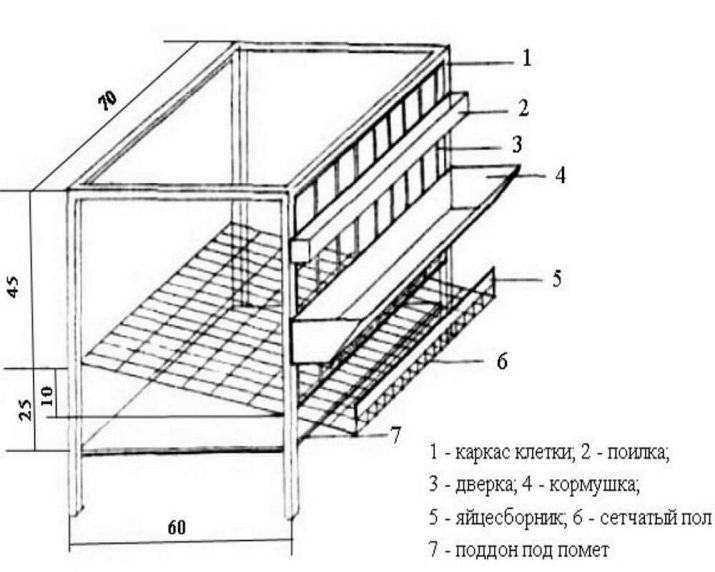

To assemble the birdcage shown in the photo, you will need the following list of materials:

- metal mesh with a square mesh, mesh size should not exceed 20 mm;

- planed wooden slats, average parameters of slats 15x30 mm;

- plywood or fiberboard up to 5 mm thick;

- consumable metal products - self-tapping screws, finishing nails, hinges, perforated mounting angles, drills.

The mesh, which will be used as the main material for the walls of the cage, must have minimum dimensional characteristics. This will reduce the weight of the entire structure and facilitate the assembly process.

The size of the wooden battens is not fixed. As this material, you can use slats with different sizes. In this case, it is important to take into account the factor of the weight of the structure. The narrower and thinner the wood components, the less its final weight. It is undesirable to use unplaned wood. The presence of irregularities, splinters and wood dust can negatively affect the condition of the birds that will be kept in the cage.

For arranging the bottom of the structure, it is recommended to use fiberboard. This material has several advantages over plywood. At least one side of the fiberboard is covered with a water-repellent layer, which ensures the best possible operation in these conditions, since the bottom of the cage is the final surface on which bird droppings and other waste products of its vital activity fall.

Consumable metal products must correspond to the parameters of wooden materials. For example, self-tapping screws after screwing in should not protrude from the other side. The pitch of their thread should be selected taking into account the minimum risk of wood splitting at the moment of screwing in.The width of the fastening metal corners must match the width of the wooden battens. It is unacceptable for the corners to protrude beyond the frame perimeter.

The values of the diameters of the drills must correspond to two values: 1) the diameter of the head of the self-tapping screws, 2) the diameter of their threaded part, divided by 2.

In accordance with the names of the selected materials, a list of tools is prepared:

- sawing devices for wood (hacksaw or jigsaw);

- drill, screwdriver;

- hammer;

- scissors for metal;

- medium grit emery sheet;

- Phillips screwdriver;

- measuring instruments (tape measure, ruler);

- PVA glue;

- other related names.

Step-by-step instruction

In order to make a cage for a parrot with your own hands, detailed drawings are drawn up. They must indicate the dimensions of all constituent parts of the structure. The availability of drawings will allow preparation of parts and subsequent assembly with maximum accuracy, which will ensure acceptable product quality and its proper appearance.

Preparation

A list of parts should be drawn up, consisting of groups of elements, the size parameters and the purpose of which are the same.

- Wooden the components are sawn off from the workpiece in accordance with the specified dimensions. The sawing points are sanded with sandpaper to a smooth state. The presence of wood chips and splinters is excluded.

- Metal grid cut with metal scissors in accordance with the specified dimensions. It is unacceptable to leave open cells at the edges of the mesh fabric. The cutting points of the mesh links are processed with sandpaper to eliminate the likelihood of injury during assembly and harm to the parrot.

Procurement of parts according to the principle of grouping makes assembly easier and reduces the time spent on it.

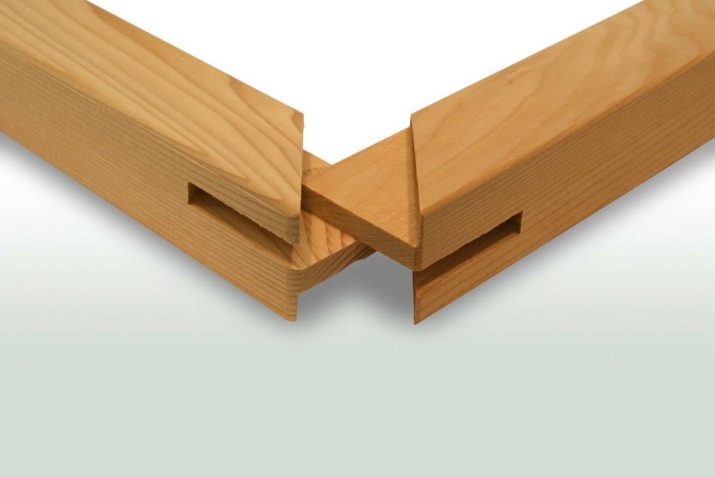

The assembly of the structure is carried out according to a modular principle. Walls, top and bottom parts are assembled separately. Wooden slats are interconnected in accordance with the drawing instructions. In order to avoid cracking the wood in the places where the self-tapping screws are screwed in, the boring hole is drilled using a drill, the diameter of which is half the diameter of the threaded part of the self-tapping screw.

In addition, a secret recess is drilled into which the screw head sits. For this, a pen drill with a diameter equal to the diameter of the head is used. The taper drill allows for chipping-free drilling, as well as to ensure the taper of the sweat, which will ensure the quality of the self-tapping head fit in it.

The metal mesh is attached to the slat frames with finishing nails. Their advantage lies in the presence of a small head, softness of the material and the ability to control the working length. The nails are driven into the slats in such a way that, when bent, they can overlap the mesh rods at the point of their contact. The frequency of driving in nails will be optimal if they are driven in through 1-2 links of the net.

The assembled components are assembled into a single structure. Perforated metal corners are used as parts that strengthen the strength of the joints, which are screwed with screws of the appropriate length.

Self-tapping screws tend to gradually twist as a result of the wood's susceptibility to expansion-contraction processes, due to its reaction to temperature changes and the degree of air humidity.

To eliminate this factor, to strengthen the strength and increase the durability of the joints, it is necessary to dip the threaded part of each self-tapping screw into PVA glue before screwing in.

On one of the sides of the cage, a frame should be provided, providing for the installation of a door. It consists of two rack and pinion circuits. The outer contour is the base to which the door frame is attached.

The hinges holding the door on themselves must be outside. This can limit the bird's ability to access the iron parts.

The cage should be designed with a double bottom. The first is a metal mesh, and the second is fiberboard. When designing a cage, it is necessary to take into account the availability of access to the second bottom. This will allow the cage to be cleaned regularly.

Watch the video tutorial on how to make a do-it-yourself parrot for a parrot further.

Advice

The construction of a parrot cage is not limited to assembling the main frame. For a full life, the bird needs availability of devices that provide food and water supply.

To equip these devices, you can use the properties of the metal mesh from which the walls of the cage are made. Tanks for water or food are suspended from the mesh cells using homemade hooks made of strong wire.

The container supplying water - the drinker - must be located outside the cage. Inside there is only a stand in which liquid accumulates.

For a comfortable stay of a parrot in a cage, you need to equip a perch. To do this, you can use a homemade crossbar, which lies with its edges in the mesh cells located on opposite walls. In most cases, there is no need to permanently fix the perch. It is periodically removed to clean the droppings.

The simplest accessory in a parrot cage is a swing. They are made from two pieces of steel wire. Loops are folded on both sides of each segment. A wooden crossbar is inserted into one pair of loops, on which the bird will sit, and the other pair of loops is fixed on the ceiling of the cage while maintaining the possibility of pendulum movement.

The homemade parrot cage is extremely easy to assemble. Doesn't require any special tools or rare materials. Its independent production allows taking into account the characteristics of the room in which it will be installed, and the characteristics of a particular bird.