All about polyurethane fabric

In a broad sense polyurethane Is a polymer, and it comes in completely different forms, depending on its composition. Read everything about synthetic fabric and its features in the article.

What is this material?

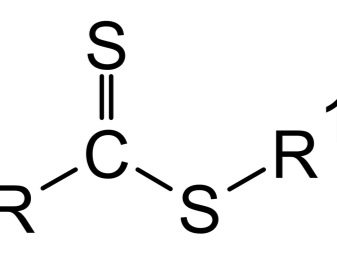

Like all plastics, it is obtained by the interaction of isocyanates with a number of polyols.... Depending on the desired end product (to make it stiffer or more flexible), the chemistry may contain other ingredients such as catalysts, blowing agents, and possibly flame retardants for mixing under high pressure to give it a high thermal insulation density. These different combinations allow different types of products to be produced.

- Medical prostheses and implants.

- Shafts, tires, shock absorbers and other parts for the construction and automotive industries.

- Textiles for the production of furniture, clothing, footwear, workwear, equipment for tourism and household goods.

- Other consumer goods (containers, bottles, diapers).

We can say that for today it is the most demanded polymerused in all areas of human life, even in the oil industry for the production of booms (fire-resistant floating booms). Polyurethane fabric is a lightweight and extremely durable waterproof material. Everyone uses it in one form or another every day - at home, in the office, in the car, on vacation for recreation and sports.

Modern man-made textiles are versatile and safe to create all kinds of consumer and industrial products to make our lives safer, more comfortable and more environmentally friendly.

Composition and properties

Polyurethanes (PU) are the largest class of polymers with various properties. There are thousands of natural and artificial polymers, others are the most famous: nylon, silicon, polyethylene, polypropylene, polystyrene. They can be thermoset or thermoplastic, hard and hard or flexible and soft... The density of the product is determined by the amount of blowing agent used, and the flexibility or stiffness is determined by the type of polyols and isocyanates used.

Properties polyurethanes are highly dependent on the structure of the polymer backbone. They can be tailored to provide high strength, high rigidity, or high flexibility and toughness. Most have good resistance to oil, hydrocarbons, oxygen and ozone. The two main disadvantages are their susceptibility to microbial attack and the propensity of aromatic urethanes to discolor when exposed to ultraviolet radiation.

Artificial leather is a composite material consisting of one or more layers of polymeric resins connected by urethane bonds, as well as a woven or non-woven textile base such as polyester, cotton, nylon or ground leather.

A PU coating is applied to the wrong side of the fabric and then processed to look more like animal hide. This makes it waterproof, lightweight and flexible, providing the most realistic imitation of leather.

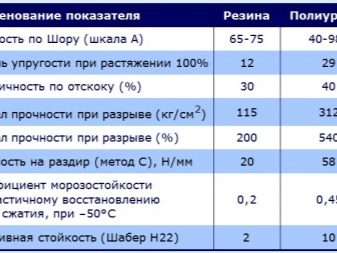

Specifications

There are many different polyurethane fabrics, the quality of which is regulated by the state standard of Russia. For clothing, haberdashery, shoe and upholstery artificial leather, these are GOSTs numbered: 28461-90; R 56621-2015; R 56626-2015; R 57020-2016 and others.

Depending on the type, they have the following characteristics.

- Breaking load from 8 to 25 daN.

- Hardness no more than 7-70 cN.

- Resistance to repeated bending, not less than 50-150 kilocycles.

- Color fastness to friction (dry and wet) not less than 4-5 points.

- The bond strength between the layers is not less than 0.3-0.5 N / mm.

- Water resistance not less than 250 mm of water. Art.

- Frost resistance from -10 to -20 degrees.

- Light fastness for light colors from 3 to 4 points.

- The amount of deflection from repeated stretching is no more than 5-7 mm.

Advantages and disadvantages

Materials like PVC contain chloride and are not biodegradable. And polyurethane fabric does not use solvents, so it does not produce harmful toxins, and most of the material will deteriorate over time.

Capable of resisting heat and moisture, which means a single PU item can be reused for longer periods than other materials, significantly reducing waste.

Main pluses:

- low price;

- many textures and colors;

- breathable;

- waterproof;

- easy to clean with a regular sponge and soap, dry cleaning allowed, machine washable;

- does not emit toxic substances, biodegradable after 500 years.

PU goods are cheaper and more convenient, they are easier to care for, they are very durable and are considered environmentally friendly. However, the material is flammable and may produce harmful carbon monoxide when burned. Such products do not crack when used and do not fade when exposed to sunlight.

What is it used for?

Scientists have found that polyurethane can be turned into thin threads, so nylon first appeared, from which stockings are made. Over the years, it has been developed into spandex fibers. Thanks to today's advances, technology makes it possible to manufacture wide range of polyurethane fabrics: from artificial leather (including suede or velor) and eco-leather for outerwear and upholstery to bags, jackets, skirts and outfits, various accessories, products for medicine and sports.In addition, the material is used to create more comfortable, durable and weather-resistant equipment such as workwear, sports jackets and raincoats, shoes and insoles.

Fact! Thermoplastic polyurethane elastomers can be formed into different fibers. When they are spun, they produce a flexible material called spandex. Elastic materials are needed for socks, bras, support sleeves, swimwear, sports equipment and more.

The main advantage of genuine leather over leatherette is its breathability and biodegradability. But in 1963, scientists from the United States invented a breathable eco-leather that is unique in its properties, it is soft and elastic and much lighter in weight.

Innovative anti-cruelty technology and make manufacturing polyurethane leather a more environmentally friendly option and less use of natural resources. Polyurethane fabrics are used in many industries, depending on their chemical composition and properties obtained during the production process.

They are the main material for the following products.

- Clothes, shoes and bags (including protective overalls for industrial production).

- Textiles for furniture and the automotive industry (upholstery, soft fillers, mattress toppers).

- Medical supplies (gloves, air mattress tops).

- Swimming and tourism products (life jackets and boats, membrane jackets and footwear).

- Baby products (reusable diapers).

L. Gore and Associates patented Gore-Tex in 1976 - water-repellent, but at the same time breathable material. Since then, it has been used in medical implants, for wire insulation, and in clothing and footwear. Gore-Tex membrane has become a fairly well-known brand that offers ski and mountaineering clothing and footwear, jackets and overalls for outdoor enthusiasts. Such equipment effectively retains moisture in all weather conditions.

Interesting! Some polyurethane foams are called faux leather for shoes, sofa upholstery, and a variety of other products.

Polyurethane fabrics are lightweight, breathable and non-breathable. As a rule, they retain their properties for at least 100 cycles in a washing machine without harm to the material. The material is easy to work with and was originally developed for use in hospitals where a durable, waterproof, reusable cloth was required.

Features of operation and care

PU textiles and artificial leather are extremely durable and because they are waterproof, dirt can be easily removed with soap and a soft, damp sponge. Mineral spirits can be cleaned, but harsh chemicals such as acetone or vinegar can be detrimental to the look. According to the care and operating instructions (always check the label on your items), most PU fabric items can be dry cleaned put in a washing machine with ordinary washing powder. thermoregulation.

Unlike other polyurethane materials, Gore-Tex has breathable pores, which must be regularly cleaned with special compounds so that dirt and sweat do not interfere

For polyurethane fabric, see the following video.