Knives for woodcarving: types and selection rules

A carving knife is the main tool of a craftsman who makes decorative objects from natural wood.... There are several varieties of this equipment, the choice of which is determined depending on the work performed.

Characteristic

Wood carving knives come in different shapes, but they will all have a rather short blade compared to a simple cutlery. This design is due to the fact that if you cut correctly during operation, the tip will experience significant pressure, and the shorter the length of the metal part, the greater the likelihood that it will not break. Like any other knives, woodworking tools are equipped with a comfortable handle, "nose", back, "heel" and shank.

The best of them have a blade made of high quality metal blade that can withstand severe stress. As a rule, for this purpose, carbon, alloy or high-speed steels of certain grades are used.

The dimensions of the blade and shank are selected depending on the tasks to be performed. For example, to perform rough work, it is better to purchase a tool with a cutting part equal to 70-90 millimeters, and for delicate work, a tip from 30 to 60 millimeters is sufficient. A standard jamb knife has a handle of about 100-150 millimeters, while the size of the blade does not go beyond 30-70 millimeters.

The main characteristics of a knife for wood carving can be seen on the example of a tool brand Morakniv. Its thin cone-shaped blade is made of laminated carbon steel, and its wooden birch handle is additionally impregnated with oil.

The length of the knife reaches 165 millimeters, and the length of the blade is 60 millimeters. The thickness of the butt is 2.7 millimeters, and the weight does not exceed 69 grams.

Views

As a rule, a wood carving master's kit includes several professional knives.

Jamb

Jamb knife is considered to be universal tool related to main incisors... The tool is used to create geometric shapes, correct lines and elements, as well as for final finishing. It is irreplaceable when creating both flat and volumetric compositions. The oblique knife has a blade that is sharpened at an angle of 60 degrees. In a set, this tool is often presented in several variations, differing in size, material to be processed and the specifics of the work performed.

A kind of jamb is a flag knife, its appearance resembles a triangle, one of the vertices "immersed" in the handle. Such a cutter is also commonly referred to as universal.

Cutter

The cutter knife is a versatile cutter that is necessary for both the beginner and the professional. An elongated blade may be straight or slightly curved, but the back is always curved. Sharpening is carried out at an angle of 35 degrees. Most often, the cutter is used to create geometric patterns on volumetric panels. The comfortable blade is perfect for shaping curved shapes and shaping smooth lines. It is customary to call a corner a kind of cutter.

Hatchet

The hatchet knife is considered a rare type of carving knife, despite the fact that it allows you to do most of the basic work. As you might guess from the name, the instrument looks like a miniature ax, one side of which is the "heel" and the other side is the "toe". During sharpening, the required angle is selected depending on the characteristics of the wood being processed. It is customary to create a hatchet knife with your own hands before performing a specific job. He can use not only both sides, but also the middle part of the blade.

With the help of this ax, slots are created and relief grooves are cleaned. The central part of the tip copes well with volumetric elements.

Bogorodsky knife

Bogorodsky knife, also called "Tatyanka", is used for the execution of Bogorodsky carving - creating handmade wooden figurines. Outwardly, it looks a bit like a European cutter, but it has an elongated blade and a shortened handle. It can be used for both initial work and final finishing. The tool has a smooth edge, but is partially sharpened. This variety can exist in several sizes, and the length of the blade ranges from 3 to 9 centimeters.

If the interaction is carried out with soft wood, then one of this knife can implement the entire cycle of work. The comfortable handle creates the necessary pressure on the blade, and therefore with the help of the Bogorodsky knife, you can make the most "power" thread.

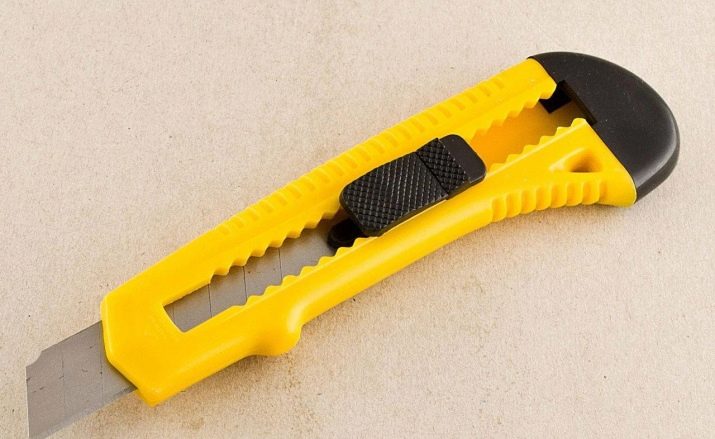

Clerical

Some beginners believe that for wood carving is suitable an ordinary stationery knife with sharpened replaceable blades. The tool is quite inexpensive and allows you to adjust the length of the tip, but its use is very dangerous. Since during the working process pressure often falls on the side surface of the blade, it can quickly break and, flying off, scratch the workpiece. Nevertheless a clerical knife will be useful for initial marking.

Manufacturers

The leading manufacturers of knives for wood carving include companies Flexcutsupplying to the market sets of quality knives, as well as Frost, in addition to the incisors, it also produces spoon cutters. Company Dem-Bart specializes in butt decorating tool, and "Petrov and Son" produces straight knives of various types.High quality guaranteed by a Swiss brand Pfeil, in the assortment of which you can even find left-hand knives-jambs, as well as the Swedish brand Mora.

Appointment

A knife designed for wood carving allows the craftsman to make decorative objects from natural wood. The main feature of the product is the presence of a shortened blade, which allows for delicate work. Using a handicraft knife, you can create intricate patterns and create a deep volume, as well as make indentations in spoons and other products. Some tool varieties are suitable for contouring, embossing, curly or screw carving, while others are ideal for cutting out a miniature figure in stages. The knife allows you to clean grooves and background, as well as to remove chamfers... Of course, it is he who is the main tool for artistic carving.

Features of choice

For novice craftsmen, it is recommended to purchase not a separate knife, but a ready-made set for carving, including, for example, rivets and glucarzes. Products receive good reviews both domestic and foreign manufacturers, therefore, the choice of goods on the market is quite extensive. For the initial work, it will be enough to buy a small kit, including models with straight round blades. Over time, some of the knives can even be made with their own hands, so that the handle is fully consistent with the outlines of the hand, and the hand does not slip during many hours of work.

Before buying, it is important to find out not only the country of production and the manufacturing company, but also the brand of steel used. Already when choosing a knife, you should definitely hold it in your hands, evaluate the convenience of work and comfort of movement. It is important that the blade is strong and well hardened, and that the surface is free of rust and any defects. The entire cutting part must be securely fixed in the handle without any play, unless, of course, this is a model with replaceable blades.

It is great if the handle of the knife turns out to be wooden, as it will be convenient to hold it even with sweaty hands. However, the use of high-quality plastic is also convenient.

It is necessary to track the smoothness of the handle, as well as the absence of cracks, snags and burrs. Carving is most convenient with a knife with a cylindrical, conical or mushroom-shaped handle. On the market today there are models with anatomically shaped handles and special recesses for the fingers, but most novice craftsmen find them uncomfortable. By the way, the included scabbard is a nice bonus.

Sharpening rules

Sharpening knives with high quality is an important condition for making beautiful and neat carved products. To perform this procedure, you need several bars, both coarse-grained and fine-grained, an old leather belt that helps to straighten, as well as GOI paste or its analogue. Before sharpening a knife, the bar must be wetted. The work begins with the participation of a coarse grit tool - the cutter is positioned on it at the required angle, and then sharpens by pressing away from itself. Usually an angle of 15 to 24 degrees is chosen. Further, the sequence of actions is repeated on a medium-grained bar - as a result, a clear sharp edge should appear at the knife.

The final stage is carried out on a diamond stone of fine abrasiveness, during which the metal chamfer that appeared in the previous stage is removed. Finally, a layer of paste containing chromium oxide is spread over the belt and used to polish the knife edge. By the way, lapping on the belt can be carried out more often than full sharpening, allowing you to quickly correct a slightly dull cutter.

A knife for woodcarving "Bogorodsky" is presented below.