All about plane thread

For a long time, it has been customary to decorate your home and household items with various ornaments. The most practical material for this was wood. Our ancestors have identified many benefits when working with wood. The main one is convenience and ease of processing. In the modern world, wood products also remain popular, and handmade are of great value. A fairly common woodcarving technique is flat-relief, and its advantage is that everyone can master it.

Features and types

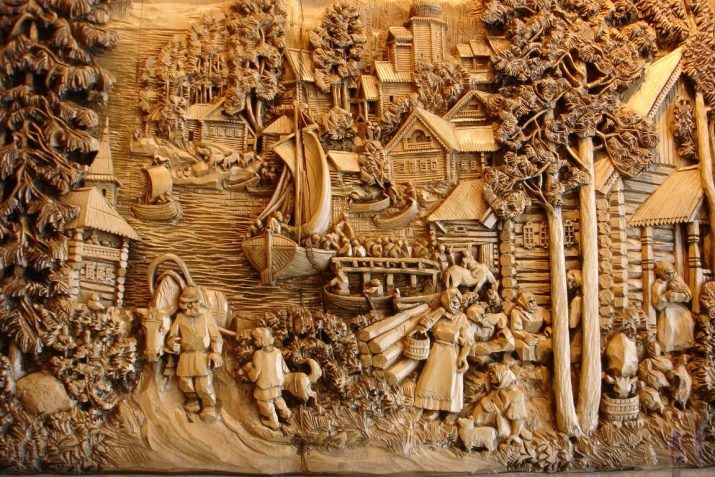

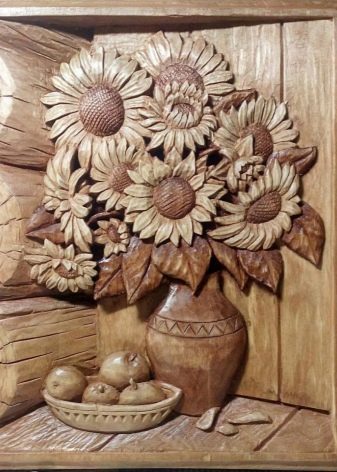

The carved nature of flat-relief carving is a deepening or bulging of the background by about 5-7 mm around the ornament. Due to this, the image becomes three-dimensional and retains the height of the embossed parts, having the same background depth. The sketch is based on various images of animals, birds, plants, humans. You can also work out even the smallest details. Often such patterns are used to decorate dishes, household items, furniture, balusters.

When performing this technique, it is customary to distinguish types of technology:

- with a painted background;

- with a matched contour;

- with pillow background;

- with a selected and underlined background.

It is extremely difficult to distinguish techniques from each other, since a plane image is characteristic of wood carving. It often happens that all types are intertwined in one composition.

Tools and material

Advice for beginners in flat-relief carving - it is better to choose a soft wood. These include: aspen, linden, pine. More experienced carvers use hard types of wood: beech, walnut, acacia, hornbeam.

To perform this type of thread, you should prepare tools:

- files;

- electric drill;

- ruler;

- planer with a jigsaw;

- jamb knife with a hacksaw;

- chisel;

- compass and eraser.

Execution technology

Prepare first material for the thread. The wood should be flat, planed and cleaned with sandpaper. If the background is light, then it is treated with a jointer, and the dark one is painted over. The ornament for manufacturing is selected from specialized books, albums, magazines, and tracing paper or carbon paper is used for accurate execution. For beginners, it is better to use a sketch applied directly to the workpiece itself.

Jamb knife - the most important tool of a woodcarver... When working, it is held firmly in the hand, directing the blade in its direction, and with a slight pressure, the ornament is brought out. The knife should be on a slope. After the incision is made, the incision itself is made. All roundings are made with one chisel corner, with the correct blade width. For a product with an engraved thread, you will first need to make a blank, and the process itself begins with cutting out the background. In the future, it is rounded off.

All cuts are made only with semicircular chisels. It is very important to maintain a 30 degree incline of the cut.

The technology for making a thread with a pillow background is similar to the first type.... It differs from the veiled technique only in that the contour is slightly lower than the pattern itself. Accordingly, the amount of work when performing such a thread is much greater. Suitable for more experienced craftsmen. At the end of the work, grinding is carried out with sandpaper or fine sandpaper. Beginners should start with a thread with a selected contour. Such a thread is considered easier to perform, because the contour is removed at an angle of 30-45 degrees of inclination to the plane. No further grinding is required.

When performing the technique with an undercut or selected background, the difference from other types is that a depression is made in a circle from the main pattern, and the image seems to rise above the base.

Drawings with the selected background are used in the manufacture of three-dimensional wooden compositions. At the end of the work, the product is tinted with various stains or dyes. Then they are sanded with sandpaper. Can be coated with colorless varnish.

In production, flat-relief carving is performed on special CNC machines. In turn, the technology of the machine tool can also be divided into 2 types.

- Carving in the body: the background of the thread is 4-5 mm lower from the top of the fabrication, and the wall is cut with a 30-60 degree cutter. The rest of the drawing lines and the decorative part are cut with a 90-120 degree cutter. This type is shown in the image of an owl in flight.

- Slotted flat-relief thread. With this method, the main background is cut directly at right angles, and the outer wall of the thread is cut in half or a small part using a 30-60 degree cutter. The appearance of this technique is shown on a stand.

Despite the ease of doing work on the machine, some technical rules should be followed... One of the main things is to respect the size of the picture and cutters suitable for it, so that when cutting out the background, use as few cutters as possible and significantly reduce the time for changing the working tool. Also, when forming a picture, one should observe the structure of the composition, its consistency and completeness. The weaves must be strictly observed. To make your work easier, you can use a hand-drawn sketch and output it through the CorelDraw program.

You can look at the flat-relief woodcarving in the video below.