Silver plating of parts by electroplating

Due to its many unique properties, silver is used not only in the manufacture of jewelry and expensive cutlery. There is a great demand for a procedure called silvering parts, during which objects are covered with a thin layer of light metal. Let's take a closer look at the galvanic method, which can be implemented at home.

Process features

Silver plating of parts by electroplating (electroplating) is very popular both among professionals who have been working with metals for a long time, and ordinary people who want to cover another object with a layer of precious metal. This technique has found its application in the coating of copper figurines. Using electroforming, you can create objects of any complexity. Also, the technique is widely used to restore damaged surfaces and elements.

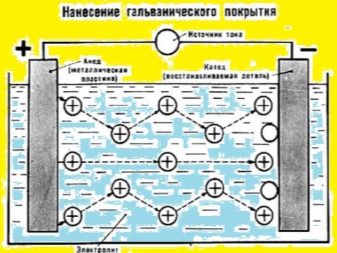

The main feature is immersion in a special substance (electrolyte) of the object required for processing. For work, a liquid is used, which contains metal salts. Covering will not work without them. During the procedure, the salts begin to dissolve in water into positive and negative ions. This process is called electrolysis.

It should be noted that electrolytes are wonderful conductors. While the object is immersed in liquid and connected to electrical power, electrical current will constantly flow through these particles. The electrolytic action starts the necessary processes.

Required tools and materials

Before you start silvering, you need to prepare the following.

- Reliable capacity.

- DC power supply.

- Scales (you can use a pharmacy or jewelry, so that you can work with compositions and small items).

- Electrolyte.

- Electric stove.

- The wire.

- A set of electrodes (anode and cathode).

You may also need silver nitrate (aka lapis crayon, which you can buy at any pharmacy) and sodium salt (an element with sodium cyanide).

The exact list of required tools and materials depends on how the silvering will be performed and what objects need to be coated with a thin layer of metal.

When choosing a power source, choose a device that can adjust the electric year. If you are going to work with objects the size of a large apple, you need to use a rectifier that is designed for an output current of up to 5 A. In the event that you need to process a small object, 0.5 A or even less will be sufficient.

When using the galvanic technique, 12V chargers can also be used. Such gadgets are found in almost every home with gadgets. Old type batteries can also be used as a power source for the silver plating process. If it is necessary to reduce the current flow, experienced specialists recommend using bypassing.

The tray that you will use in your work must be strong and roomy. Another two important characteristics are resistance to reagents, electricity and high temperatures. A glass container with a wall thickness of 0.5 centimeters is great. In the house, you can find an aquarium or a jar with a wide mouth.

For a positive result, the components used must be accurately weighed. In this case, accurate scales will come in handy, preferably electronic. It is convenient to work with them. It is recommended to check the device before use.

To complete the procedure, you will need precious metal plates. They act as electrodes. These are donors, the molecules from which will be transferred to the processed object. Through them, the current passes to the electrolyte. It is better to choose stranded wires, made of copper, cross-section - 2.5 sq. mm. If you need to heat up during operation, you can use a conventional microwave oven.

An oven (electric or gas) or electric stove will also work.

Safety engineering

When performing silver plating, it is imperative to adhere to safety rules. Otherwise, you can not only damage equipment and consumables, but also harm your health. The room where the work is done must be ventilated. Open windows for fresh air and circulation. If the room has no windows, turn on the air conditioner or install a fan.

Be sure to protect your hands as well as your respiratory system. Use rubber gloves and a respirator. Use quality products. Also wear old clothes that you don't mind ruining. Do not consume food or water during work. Particles of dangerous and aggressive reagents may remain on the hands.

Let us mention the possible dangers in the process of work.

- Evaporation of chemical compounds.

- High temperatures.

- Electricity.

- Destruction of used containers.

- Contact with caustic compounds on bare skin.

Progress

Preparation

Before you start silvering, you need to properly prepare the product for processing. Items must be thoroughly cleaned of dust, rust, greasy marks and other things. You can choose a manual cleaning method or use special equipment such as a sander. When using abrasive products or harsh metal sponges, be careful not to damage the product.

If there are deep scratches on the object to be treated, they must also be thoroughly cleaned out. Otherwise, the metal atoms will not form a strong enough bond and will simply become a precipitate.After the first stage of cleaning has come to an end, the product must be placed in a special solution. This will require an acidic or alkaline composition. Care must be taken at this stage so as not to burn the skin.

When silvering steel products, they can be immersed in sodium phosphate for several minutes, heating the composition to 90 degrees Celsius.

For cleaning copper objects or products from its alloy, you can use conventional detergents or solutions based on soda. Another option is to use sodium phosphate, but in this case it should not be heated. In some cases, cleaning using chemical compounds may not give results. The leftovers can be like this.

- Traces of paint or enamel.

- Burnt solidified fat that has eaten into the surface.

- Deep corrosion damage.

- Slag.

- Resin residues.

If after the first cleaning it is not possible to achieve the desired results, you need to carry out this procedure several more times. Do not start silvering the object until it is completely cleaned.

The main stage

To carry out the process at home, you can use a special saline solution. Muric acid is the main component for work (hydrochloric acid HCl). It is also called soldering iron. The composition has similar properties to sulfuric acid. The silvering method is as follows.

- To begin with, a steel plate and a silver workpiece must be connected to the supply clamps. Be sure to observe the polarity during the process. Silver must be connected to plus, and the second element to minus.

- The working container is filled with clean water and hydrochloric acid. The required proportions are 5: 1.

- Two elements (the donor and the object to be silver-plated) are placed in the composition. The clamp on the part is connected to a place that does not need silvering. It is also possible to move the clamp throughout the entire galvanization process.

- In order for the silver layer to turn out even and homogeneous, the composition must sometimes be mixed.

- Note: while preparing the electrolyte, the acid must be added to the water gently, in a thin stream. After the liquid is gently mixed with a glass stick.

- A small distance must be maintained between the positive and negative electrodes. In the process of work, the object will be covered with a thin layer of precious metal, it is difficult to arrange a thick coating. This process can take several hours.

When carrying out the procedure at home, it is necessary to determine in advance what kind of chemical reaction should result. When choosing, you need to take into account the metal with which you need to perform silvering. Lead is an excellent anode for coating with precious metals. Do not forget to update the composition in which the galvanization process is performed (electrolyte).

A visual example of applying a thin and even layer of silver to the surface of another material can be found in any home. This is an ordinary mirror. By combining glass and precious metal, the desired result is achieved.

Also, the silvering technique is great for brass, copper and various objects from their alloys.

When carrying out work at home, the selected workpiece must be coated with nickel and only then proceed to silvering. To prepare the required solution, you need to prepare the following components:

- 40 grams of iron-cyanide potassium and the same amount of potassium carbonate (soda ash);

- 70 milliliters of ammonium hydroxide in the form of a liquid solution;

- 10 grams of silver chloride;

- 15 grams of edible salt (sodium chloride);

- a liter of distilled water, while boiled or tap water will not work due to the presence of foreign impurities;

- you need a rod of a graphite construction pencil, it will play the role of an anode.

The attached diagram will help you to do the work. It clearly demonstrates the process.Here is another pictorial diagram that shows in detail the essence of the method described in the article. In the image, everything is very clear.

Completion

After the process has come to an end, it is imperative to get rid of the remnants of the chemical solution. They need to be poured into a sink and rinsed with plenty of running water. All parts used during work must be wiped dry. Use heavy paper towels or a soft cloth for this.

Take off your work clothes. Throw away disposable protective equipment immediately; they cannot be reused. Wash your hands thoroughly with soap and water. Leave the room to ventilate until the air is completely clean. It is also necessary to wash the clothes thoroughly, preferably rinse them thoroughly in order to finally get rid of the reagent particles. Remember to clean containers and tools that have been used in the process and that have come into contact with hazardous and corrosive components.