Sewing machine "Chaika-2": description and operating instructions

Despite the widespread development of the textile industry, home sewing machines remain popular. Among them, even old models that were produced back in the 1970s are in demand. But real knowledge about setting up and adjusting such a technique is difficult to find. It's time to fill that gap. We will provide a description and instruction manual for the sewing machine "Chaika-2".

Peculiarities

It is appropriate to start the conversation about the model of a foot sewing machine "Chaika-2" with the fact that it is arranged approximately in the same way as other models in the "Chaika" series. Moreover, the internal structure of the once popular "Podolsk" series also has no noticeable differences. There is not much difference in the operating mode.

The only noticeable difference is the additional varieties of the zigzag stitch present in some modifications.

Internal organization

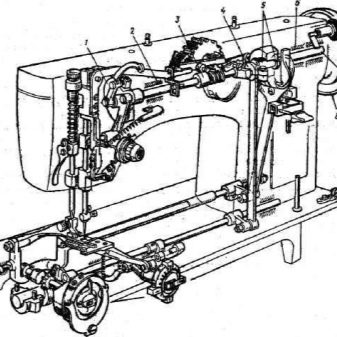

"Chaika-2" is equipped with a shuttle device, a stitch type detector, a zigzag width regulator, a bobbin rod, a winder and a flywheel. One lever is responsible for displacing the needle, and another for attracting the threads. A needle plate is provided. Other parts include:

- platform;

- clamp detail;

- a pair of lids;

- lever raising the foot;

- thread tension controller;

- needle bar;

- tension washers;

- needle shift lever;

- return feed lever;

- zigzag handle, stitch controller, comb raising, turning off the copier body;

- picturesque design.

Application, adjustment, repair

The sewing machines "Chaika" and "Podolsk" can work with:

- a cloth for sheets;

- chintz;

- satin fabrics;

- silk fabrics;

- fabrics for linen;

- cambric;

- elite varieties of silk;

- calico;

- woolen fabrics for suits;

- thick wool-based pieces (for coats) and sturdy cloth.

According to the specific task, the following options can be used:

- needles 70, threads 65;

- needles 80, threads 65;

- needles 90, 100 or 110.

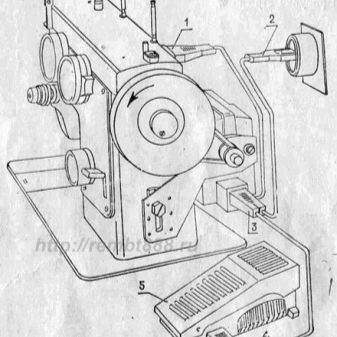

The instruction manual provides for the introduction of the needle into the needle holder, and then fastening to the stop with a screw. Only after that the upper and lower threads are tucked in. First, they work with the upper thread. Pull the spool rod out of the sleeve cover until it stops. Place the eye of the thread take-up in the upper position by rotating the handwheel.

Next, the clamping piece is raised. They put a thread winding on the core. Insert the upper thread into the passes of the thread guide, exactly between the washers of the stretch controller. Then it is pushed into the opening of the spring attracting the threads, held under the thread take-up hook, and inserted through the hole in the thread take-up lever into the wire thread guide. Next, it remains to pull the thread into the thread guide on the needle bar and place its tip in the eyelet at the operator's position.

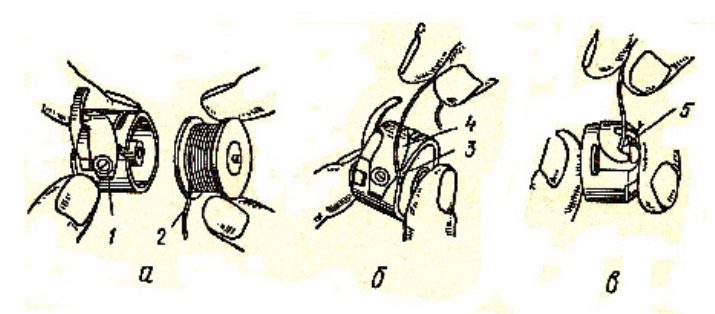

The lower thread loading starts by removing the bobbin case and bobbin. This operation is carried out by turning the element that puts the needle at the highest point. Next, slide the plate and grab the latch lever with two fingers. Then pulling out the bobbin case is not a problem.

The manual also describes the steps for winding thread on a bobbin using a winder.

When this is done, insert the bobbin cap into the hook. Care must be taken to ensure that the needle is at the highest point. If the cap is inserted correctly, the latch lever is spring loaded. When the lid is opened, he seems to be trying to return. When you are about to start sewing, you need to pull the bobbin thread onto the needle plate, and then, clinging to the upper thread, pull the thread in the shuttle to the same plate.

On a class 116-2 machine, it is possible to adjust the stitch. The power of the backlight lamp is up to 15 W. The weight in the factory case can be up to 18.5 kg. The outreach of the sleeve is from 0.17 m. True, this is the "Chaika-3" model, which has become the successor of the previous model. Apart from some additions, it is no different.

Experts recommend finishing products with the smallest possible stitch pitch. Then the drawing will be clearer. Offset a line when complex manipulations need to be done. An experimental stitching helps to check the quality of the firmware. Working with the upper thread tension controller, ensure that the threads are intertwined in the centers of the pieces to be joined.

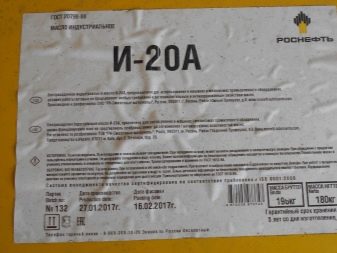

Sew on very thick or sturdy fabrics at a slower pace than usual. Help with the flywheel is very helpful (it will have to be scrolled by hand). Delicate fabrics, especially silk, pull slightly behind the foot. Then there will be less chance that the seam will tighten. To lubricate the sewing machine, only industrial lubricating oil I-20A, which corresponds to GOST 1975, is used. If the machine sews very hard or the threads get jammed, you need to clean the hook urgently.

How to learn how to sew on a sewing machine "Chaika-2", see below.