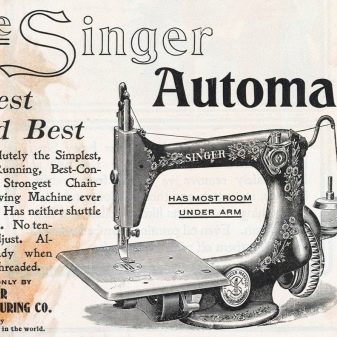

Vintage Singer Sewing Machine

The Singer sewing machine of the late 19th and early 20th centuries is still of great interest to many consumers. Most of the antique items are still usable. Legendary antiques fit perfectly into the interior of any apartment.

History

The creator of the world famous sewing machine is Isaac Singer. From 1850 he began to live in New York, where he met a local manufacturer of sewing machines. The designer dedicated Singer to the principle of his own sewing machine. The product was characterized by a circular movement of the needle. The thread was constantly entangled in the vertical shuttle.

Isaac Singer was impressed by the design. Within 10 days, he improved it. Singer invented the up and down movement of the needle. All sewing devices still have this way of moving the needle. The inventor has introduced 4 important innovations:

- the horizontal position of the shuttle led to the fact that the thread stopped tangling;

- the use of a foot drive and a presser foot created additional convenience for the seamstress;

- a leg-holder and an erected board such as a table contributed to the convenient placement of the fabric for sewing;

- all products were supplied with instructions for use.

These improvements made it possible to increase labor productivity many times over. The designer acquired a patent for his invention. In addition, it was he who came up with the idea of repairing the house by replacing individual parts. Before that, broken products were sent to the factory for repair or thrown away. Singer machines quickly became in great demand all over the world.

In the late 19th and early 20th centuries, the Singer Corporation produced many models with various names.Sewing machines were produced in different countries under the license of Singer, since at that time the company was the only patent holder for the right to manufacture such products. The construction of the Russian plant for the production of Singer sewing machines was carried out in the city of Podolsk near Moscow from 1900 to 1902. Subsequently, products under this brand were produced there for almost a century.

The year of manufacture of Singer sewing attachments can be identified by the serial number. Until the beginning of the 20th century, it consisted of only numbers, for example, in 1871, products were released with numbers from 611.000 to 913.999; in 1899 - from 15.811.500 to 16.831.099. After 1904, a letter was added to the numbers. So, modifications of 1904 can be identified by serial numbers from B-1 to B-791.500, 1935 - from Y-9.633.847 to Y-9.999.999. The country of origin was encrypted in the letters. So, the letter "A" meant that the model was produced in Podolsk (Russia), "B" - in the city of Elizabeth (New Jersey, USA), "Y" - in Scotland.

What is valuable about cars?

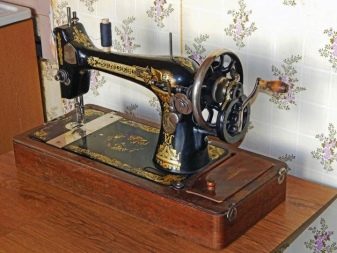

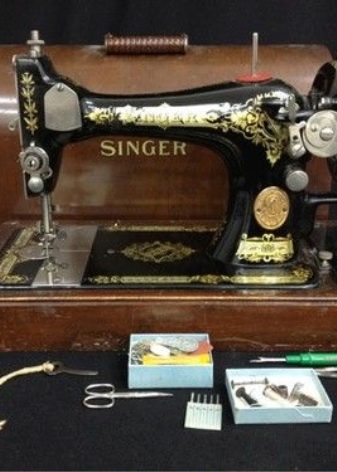

Singer sewing machines produced in the late 19th and early 20th centuries are of antique value. The older the product, the more expensive it is. There is an opinion that precious metals were used in the manufacture of sewing machines from 1886 to 1930: gold, silver, platinum, palladium. You can check their presence with a magnet. It is necessary to guide them along the metal frame of the product. Precious metals are not attracted to the magnet.

Some consider the use of precious metals in the manufacture of sewing devices a myth. Existing antiques show signs of heavy use, and precious metals are known for their softness and fragility. The products would not withstand such a heavy load.

Singer sewing machines are appreciated for their simplicity and ease of use. They handle very complex tailoring. Most of all they are appreciated for their reliability, durability, high quality in work. They are in no way inferior to some modern models. Antique products work without the use of electricity, but, according to some consumers, they can cope well with leather products, leaving even stitches on very difficult types of material. Any dense fabric is subject to them.

The old Singer sewing machine has reached its end of life as a production tool. In the modern world, a rarity is most often used for interior decoration in a retro style.

Model overview

Singer sewing appliances of the late 19th and early 20th centuries had a standard look. All sewing machines of the first editions were equipped with an old-fashioned shuttle. The shuttle was not round, as in modern modifications, but an elongated look. A long bobbin with thread was inserted into it. Such a machine made it possible to sew without gaps. The needle looped twice for the nose grip.

The production of sewing devices with a swinging shuttle was also launched. The device had a shuttle course. Some modifications were equipped with an original bobbin winding mechanism. There are many types of antique Singer horizontal shuttle units.

The modifications were distinguished by the presence of one or two lines. Some of the manufactured products had only one straight line. Other sewing household appliances could also perform a zigzag line.

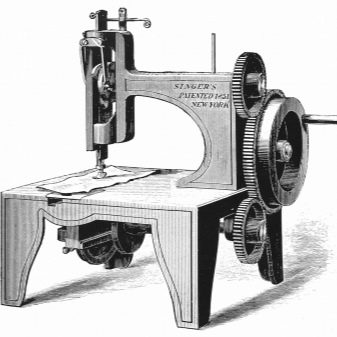

Sewing devices were equipped with a hand or foot motor. The flywheel of Singer products was notable for its massiveness. Hand-driven cars had 2 gears screwed to the body with large bushings. If necessary, the screw sleeves can be unscrewed and retightened.

On some models, a wheel-operated foot pedal replaces an awkward hand lever. By pressing the foot on a special pedal, a person can easily operate a household appliance. The designs were constantly improved. After a while, appeared modifications equipped with an electric drive.

At the end of the 19th century, the workshop of the Russian merchant Popov began the production of sewing machines under the Singer brand.The features of these sewing devices include shuttle movement along the machine. The thread was pulled primitively due to the square section of the needle holder. The thread passed through the holes in the shuttle, its tension was poorly regulated.

Another disadvantage of the design is the low grinding speed.

How to setup?

If the antiques settings fail, you need to adjust them correctly. Adjustment can be done by yourself... Failure caused by skipped stitches indicates that the needle is incorrectly seated. Stitch slippage occurs when the needle is too high in relation to the hook point. It can also be caused when working with very dense material. The rougher the fabric, the more the foot should be pressed. When adjusting the Singer sewing device, it is recommended to lower the needle. First, remove the presser foot, throat plate and front cover. Then it is necessary to clean all the parts and the compartment from dirt. The bobbin must be carefully inserted into the bobbin case, then adjusted with the screw.

With the stitch plate removed, turn the handwheel, check the correspondence of the hook nose with the needle tip and the groove. It should be just above the eye of the needle. It is very important that the needle is perfectly positioned and that the thread is correctly threaded from the side of the elongated indentation. Old modifications of the Singer brand provide for finding the cut of the flask on the right side. The thread must be inserted into the eyelet on the left. The distance between the hook tip and the needle must be carefully aligned.

The shuttle spout must fit exactly into the loop.

If the sewing device has not been used for a long time, it must be carefully treated with special machine oil. For this, there is a hole on the body of the device. Some important components on the bottom also need lubrication. To do this, turn the machine on its side and lubricate all metal parts involved in friction. Oil can be drawn into a medical syringe and instilled into the existing holes. For the substance to penetrate into all hard-to-reach places, it is necessary to drive the device at low speed with the foot raised without inserted thread. Excess grease is removed with a napkin.

When the flywheel is jammed, it is recommended to remove it and treat it together with the shaft with oil mixed with kerosene in a 1: 1 ratio. To avoid damage to the rarity, it is necessary to ensure that the operation is carried out strictly according to the instructions. While sewing Do not pull on the fabric, otherwise the hook nose may be damaged. The flywheel is allowed to rotate only in its own direction.

It is not allowed to lower a needle with a threaded thread on a bare plate. Do not sew after raising the presser foot up.

In the next video, you will find the restoration of an old Singer sewing machine.

Thank you for the article. Especially for the description of setting up the typewriter. Unfortunately, we are not alone. I really love to sew. I inherited her Singer sewing machine from my grandmother. She stopped spinning, i.e. jammed. While I was looking for a master, the children took it away and handed it over to scrap metal. I was very upset, because my grandmother replaced my mother. Now I want to buy and restore a vintage typewriter. I may be weird, but I enjoy sewing on these lovely machines. They remind me of a carefree childhood.

As I understand you ...) I have been able to work on automatic modern sewing machines for a long time, but when my mother died, she took things apart and found an ancient manual sewing machine made in the city of Podolsk in the 60s, made (maybe someone else remember those?). I saw such in our city museum as vintage.However, it works and how good it is!) Now I have dropped everything and I write only on it!) My mother still sewed on it, and then I learned to sew on it at school and works flawlessly to this day! So much for the vintage.