Singer sewing machines: models and tips for choosing

Singer sewing machines are a true legend, which laid the foundation for the massive popularization of the sewing business. These reliable, convenient, functional units are easy to set up and operate, suitable for a variety of sewing operations. Fans of the brand are often interested in whether the Singer models differ from the Zinger and what is the history of the company. In fact, a brand with a century of experience has never changed its name, and its technique is still as perfect today as it was a century ago.

Modern sewing machines Singer 8280, Tradition 2282, Fashion mate 2290 allow you to perform dozens of necessary operations. Devices easily cope with overcasting the edges of fabric, connect it curvilinearly or in a straight line.

History of creation

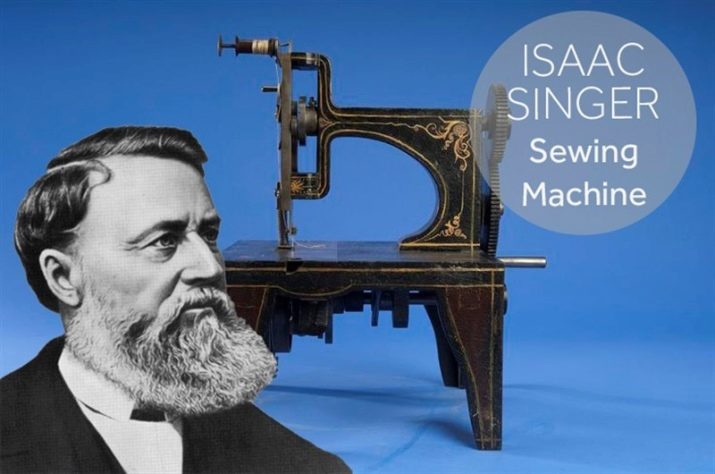

The creators of technology have been thinking about the mechanization of manual labor for a long time. The first sewing machine was patented in 1790, but did not gain much popularity. Following her, the Frenchman Timonier, whose factory was destroyed by rebellious tailors, fearing the devaluation of their labor, and the American Hunt, released their prototypes. Played a role in the mechanization of sewing and Elias Howe is another enterprising engineer from the United States. It was at his enterprise that the young Isaac Singer once came to be hired as an employee.

Howe's sewing machines, although they had a patent as an invention, were too "raw" in technical terms. Despite the acceleration of the sewing process, the technique tore the thread, confused it and, in general, turned the life of any dressmaker into a series of problems.At the same time, the unit cost $ 40 - a lot of money that the enthusiast Singer once invested in the acquisition of a sewing machine. In a short time, he came up with many innovations, refining the prototype technique so that it allows you to sew with comfort.

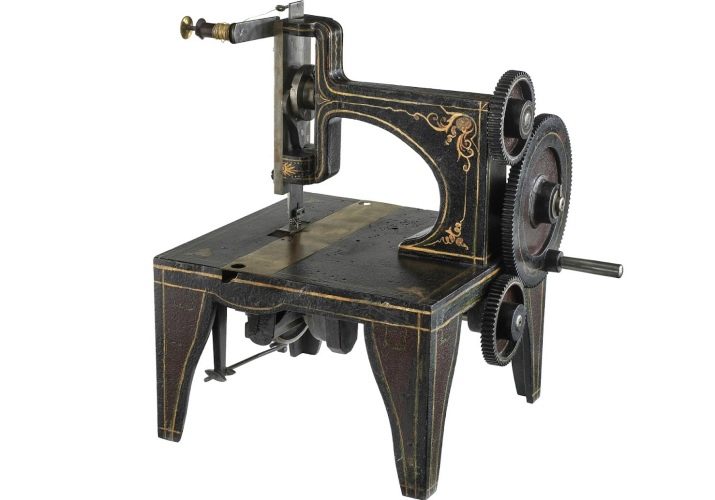

In 1851, Isaac Singer officially patented his developments. His sewing machine received:

- additional table for convenience of work;

- foot pedal to speed up the sewing process;

- adjusting the thread tension;

- horizontal shuttle mechanism that does not confuse the stitching.

At first, the inventor was forced to pay Howe royalties on every car he sold. Subsequently, Singer managed to resolve this issue and did not give anything to the prototype manufacturer. The first Singer sewing machines appeared on the mass market as early as 1854 thanks to Isaac's partnership with a lawyer named Clarke. The investor invested in the opening of a plant in New Jersey, but the quick profit was in no hurry to flow into his pockets.

The rather high price tag - $ 100 - frightened off potential buyers. Employers were not ready to mechanize the work of tailors, and only representatives of the poor social stratum thought about sewing clothes at home on their own.

Everything has changed, it was only necessary to introduce a few innovations.

- Hire a manager to solve business issues.

- Offer payment by installments to buyers.

- Present a novelty competently. The product was advertised with leaflets in churches and other crowded places. At fairs, stylishly dressed, beautiful young women demonstrated the work with the typewriter. They started talking about Singer products.

- Create a work scheme based on the franchise principle. Singer provided the name and technology. His network partners produced and sold the product themselves.

- Supplement the mechanism with instructions with a detailed description of the rules for sewing, adjusting, adjusting, caring for the sewing machine.

- Arrange warranty service and create the first network of service centers.

Singer also came to Russia through a franchise. From 1887 to 1902, the Singer Manufacturing Company operated in the country, importing all goods from abroad. Subsequently, a company of its own was created in Podolsk, which in 11 years increased production volumes to 600,000 units of equipment per year and developed a sales network to 2,500 stores throughout the country.

In 1918, the Podolsk plant was nationalized. In 1923, on its basis, from spare parts supplied by the German department, equipment was produced under the brand name "Gosshveimashina".

Since 1931, the Podolsk trademark was introduced. At the same time, all sewing machines were still no different from the classic Singer model and, in fact, were its exact copy.

Today the company, founded by Isaac Singer, is called SVP Worldwide and has subsidiaries in 180 countries.

Are Zinger and Singer the same thing?

The persistent myth that Singer is not an original machine, but Zinger is a real manufacturer of sewing machines, is long overdue to debunk. The equipment produced by Isaac Singer's company under license in any of the countries of the world has never changed its name. The first production models in the United States were labeled as Si Man Co or Simanco - such a mark was put on parts. The surname of the founder of the brand is read as Singer, and this pronunciation has always been a priority.

There are no Zinger machines. And the German, and Russian, and Italian typewriter of the past years differ from each other only in the language of translation of the instruction. There is no difference in the style of the trademark - this is Singer, without any variations.

Advantages and disadvantages

Among the obvious advantages of the Singer machines, the following points can be noted.

- Wide range of prices... You can find an option for any budget and for any need.

- Reliability and build quality... The company is responsible for each released model, constantly monitors all production processes.

- A wide network of service and dealer centers. Getting service under warranty is easy.

- Attractive design. Sewing machines live up to their status as top sellers.Each line is different.

- Easy to set up and maintain... Modern machines require little or no attention.

There are also disadvantages. Against the background of competitors' offers, Singer is confidently among the top 10 manufacturers today, but does not set quality standards. Without tuning, the sewing machine sews worse than you might expect. Branded accessories are quite expensive. Electromechanical models are quite noisy.

Antique Models

Antique models of Singer sewing machines include all equipment released before the advent of electromechanical versions. You can recognize them by the Russian "Singer" or Singer in the Latin alphabet on the case. At the same time, the marking of equipment in those years was determined not by the model, but by the enterprise and the year of manufacture. The letter "A" indicated that the equipment was produced at the Podolsk plant of the brand. Latin "B" marked American cars from New Jersey, Scottish ones received the designation "Y".

Antique Singer machines feature an extended hook, similar to the one used in spinning wheels, with a matching spool. When moving, the needle forms a loop in them 2 times. Later models have a horizontal or vertical swinging hook, a device that automated the winding of the thread.

The older Singer models were either hand-operated or foot-operated. In the first case, the table-stand served for comfort, and in the second, it had a practical function, since there was a foot pedal at the bottom.

Modern species and their functions

Singer's current product range includes electronic and electromechanical models. The devices are presented in compact and full-size versions. The lightest car weighs no more than 5.5-6 kg. The dimensions of the fully functional units are noticeably larger.

A full-fledged foot pedal is available in devices with an electromechanical drive.

A sleeve platform for individual sections on the most powerful machines can act as a shoe platform - for repairing, sewing shoes.

But it is not present in all models and is usually quite massive compared to the technology of previous years.

Electrical

In this category, the company produces sewing machines of the following lines:

- Patchwork for patchwork, with microprocessor and key;

- Starlet - budget microprocessor machines for 60, 80, 100 lines;

- Confidence - series with microprocessor control, different number of options;

- Quantum - for embroidering letters and complex patterns, there are 150 operations.

Mechanical

The simplest and most affordable mass-market models. Singer has several episodes here.

- Compact machines... This includes the smallest and lightest models of the Promice and Studio series. This is a handy solution for novice seamstresses.

- Heavy duty... 4423 and 4411 in this series are equipped with a horizontal hook, a steel stitch plate, a powerful motor and a metal frame. They differ in sewing speed from 1100 stitches per minute, have a presser foot with an additional rise, positioning of the needle is provided.

- Tradition. Classic series of machines with 10, 19, 23 or 33 lines. The older model has an auto buttonhole and an extended set of options.

- Supera... Models in this series are a good solution for streaming sewing. Even with a minimal set of operations, you don't have to worry about the needle speed - it is 1100 stitches per minute. The models are suitable for all types of fabrics, including heavy ones.

- Simple. Stylish design models with vertical hook and needle threader. Designed for light to medium weight fabrics.

- Talent. A series of machines with a needle threader, horizontal shuttle, quite quiet operation. The models have a recognizable design, the number of operations varies from 21 to 23.

- Fashion Mate. A series with an original platform design, a wide range of functions. There are both very simple models and more expensive ones.

The lineup

Singer 8280

The most popular budget model. Electromechanical machine with swing shuttle, illumination, reverse sewing button. The machine performs only 7 operations, complete with hemming foot, sleeve platform, accessory compartment.

A good solution for a beginner seamstress who wants to get the first experience with a sewing machine.

Tradition 2250

A budget model with a minimal set of options. The machine uses a vertical shuttle, there are 10 operations available, easy function adjustment. A good choice for beginners.

Tradition 2282

More functional model of the classic series. Performs 33 operations, there is automatic looping, the shuttle is vertical, the spool is positioned horizontally. In the presence of a needle threader, reverse, a sleeve platform, raising the foot in 2 positions.

Fashion mate 2290

An electromechanical machine in a stylish design. There is support for 10 operations and a minimum set of required options.

Starlet 6660

Microprocessor machine with built-in black and white display. Sews up to 60 stitches, 4 types of buttonholes. Power of 650 W is enough for sewing medium-weight fabrics.

Heavy duty 4432

One of the most powerful sewing machines of the brand.

Designed specifically for sewing thick and heavy fabrics.

Horizontal shuttle included, 23 operations supported... The buttonhole is sewn in auto mode, there is a needle threader.

Promise 1408

A simple machine with a minimum set of functions. Convenient solution for home use. The technique is lightweight, equipped with illumination, a sleeve platform, and can sew in 2 threads. Budgetary cost and reliability are its main advantages.

Singer 1507

Inexpensive sewing machine with reverse function, pedal. The model weighs 6.5 kg, performs 8 operations, equipped with a hose platform. One of the most highly regarded models in terms of value for money.

Talent 3321

Simple horizontal shuttle model with 21 steps. The set includes a needle threader, a sleeve platform, a metal frame.

Singer 2255

Model of the Tradition series, a classic electromechanical clipper. Performs 10 lines, equipped with a vertical shuttle, there is a sleeve platform. This model is already capable of performing darning and embroidery operations, sewing on buttons. The set includes 4 legs, a thread cutter.

Tradition 2273

A budget sewing machine for home use. The model weighs only 5 kg and supports 23 operations. Includes a sleeve platform, lighting, needle threader.

Promise 1409

Electromechanical sewing machine capable of 9 operations. A simple home model for a budget. Equipped with a vertical shuttle. The sewing speed is limited to 600 stitches per minute. The set includes a switchable bottom conveyor, a pedal, a sleeve platform, an accessory compartment.

Simple 3229

The technical characteristics of the model correspond to its status. The set includes a vertical shuttle, lifting foot with 2 positions of height, sleeve platform, reverse. The machine supports 29 stitches, sews buttonholes in semiautomatic mode, there are decorative operations.

Accessories and spare parts

Today Singer manufactures a wide range of related products for its sewing machines. Additional feet can be purchased separately - as a set or individually. Among the current additions are conveyors:

- for bias inlay;

- for sewing in a hidden zipper;

- for darning;

- overlock with a brush;

- undercutting;

- hemming;

- teflon.

In addition, you can choose needles, needle threaders, spools, belts (they are better purchased in workshops), stands for increasing the usable area of the platform. You can also find HEPA filters for the most high-tech models, branded bags for transportation.

Selection recommendations

When choosing a Singer sewing machine, it is important to be guided by the following points.

- The size of the purchase budget. If it is small, you should choose a model with a minimum set of functions, but not from an unknown manufacturer, but from a company with a name. Then spending will definitely not be in vain.

- Purpose of Acquisition. If you need a sewing machine to perform the simplest basic operations, there is simply no point in buying a computerized model with hundreds of functions. For solving specific problems, it is often better to choose a coverstitch technique or overlock than the classic model.

- Frame type... The metal is heavier, but it guarantees that the equipment will work for a long time and will be repairable.

- Shuttle type... If you do not need to sew a zigzag stitch and other decorative stitches more than 6 mm wide, then there is no point in a horizontal shuttle.

- Build country... All Singer equipment is assembled in Taiwan, Vietnam, China at factories that produce equipment for most sewing brands.

Do not buy into marketing gimmicks and look for a "German" or "American" "Singer".

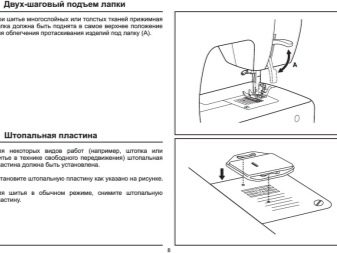

Self-configuration

To adjust the clipper before starting work, just follow the simple instructions.

- For sewing thick fabrics, machines with a 2-position presser foot are used. For the fabric to pass, it is enough to raise the foot to the upper position until it stops.

- Pressure adjustment in modern machines is usually not required... If you still need it, on electromechanical machines there is a special screw for this at the top of the case. To increase the pressure, rotate it counterclockwise.

- The clutch of the presser foot with the holder is automatic... It is enough to press the lever and release the end to install a new part. On electromechanical models, an additional retainer notch may be required.

- The upper thread tension should be in the standard position «4» regulator... To increase or decrease it, just rotate the control.

User manual

Before starting work after a long period of inactivity, it is imperative to lubricate the machine. Then you can configure it.

- Install the correct needle. Loosen the needle clamp screw. Insert a new needle with the flat side facing away from you. Push as far as it will go, fix with a screw.

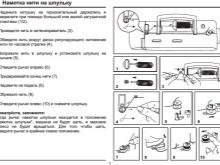

- Wind up the bobbin. Fasten the spool on a horizontal holder, pass the thread into the disk, which is responsible for the winding tension, make 2-3 turns by hand. Put the bobbin on the mount, move the rod to the desired position (to the right until it stops). Hold the thread by hand, press the pedal, wind up.

- Insert the shuttle. More precisely, the bobbin case. For this, the needle rises to the upper position, the shuttle compartment opens. The bobbin-loaded cap is set with the lever up.

- Thread the thread from above. The needle is in the up position and the presser foot is up. The spool is installed with the thread running clockwise onto the holder. The thread is guided through the thread guide, disc, pull and other elements to the needle. If an auto-threader is present, the operation will be performed automatically.

- Insert the thread into the needle. Always back away from the operator, pull out 10-15 cm.

Possible problems

Some of the most common problems with Singer machines are:

- Noise during operation. It may indicate a clogged hook section, damaged needle, or lack of lubrication. If there is no debris inside, it is enough to lubricate the equipment or change the oil in it.

- Does not sew a horizontal shuttle. The reason is the tangling of the thread. The part must be removed, manually turned the flywheel, remove scraps of pile, thread.

- The stitches are uneven. It is necessary to replace the threads, check the threading of the bobbin thread, or check that no additional pressure is applied to the material.

- The bobbin thread breaks. It is necessary to check its tension, pay attention to the accuracy of threading and installation of the bobbin case.

- Upper thread breaks... The threading order may be out of order, or the thread tension has been changed, or the thickness of the needle does not match the thread.

Advice

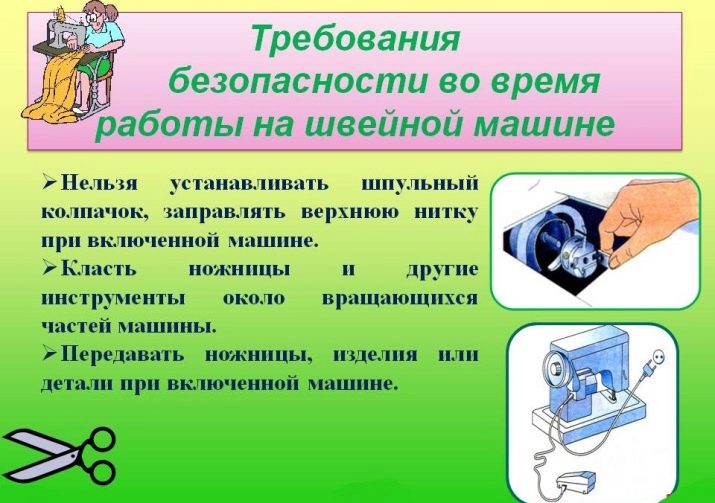

When working with the sewing machine, it is absolutely impossible to leave it connected to the network without supervision. The unit must be de-energized for any maintenance. Before switching off, you must first select the appropriate position of the controller, then remove the plug from the socket.

It is strictly forbidden to use the machine with a damaged cord.

Do not use non-standard parts - this can damage the mechanism... The wrong stitch plate will break the needle. When sewing, it is necessary to exclude contact of fingers, hair with moving parts of equipment. It is worth checking the ventilation holes and the shuttle compartment periodically - they easily clog, accumulate lint and dirt.

Learn more about sewing machines in the following video.