Sewing machines and overlocks Typical: models, tips for choosing

The Typical Sewing Machine can help people out in many situations. But even this sturdy sewing equipment must be chosen carefully. And first you have to understand all the intricacies of selection, operation and the proposed range.

Main modifications and types

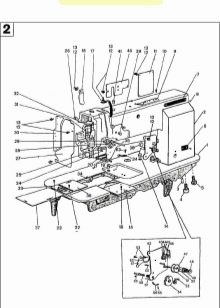

Among industrial sewing machines, it stands out favorably GC6150MD. Its characteristics are something like this:

- total weight - 65 kg;

- occupied volume - 0.3 cubic meters m .;

- lockstitch;

- suitability for processing light and moderately dense materials;

- supply of matter along the bottom conveyor;

- the limiting number of revolutions - 5000 per minute;

- equipped with a built-in servo drive;

- automatic supply of grease;

- single working needle;

- stitch length - no more than 5 mm.

The sewing direction of the needle is determined special positioner. The speed can be adjusted. The brand description mentions that the sound and vibration are 50% lower than in previous models. The designers paid special attention to energy conservation. Thanks to the well thought-out design of the drain hole adjustment of the lubricating oil flow is as accurate as possible.

If you do not need to purchase a model with a table, then the GC 6850 H can be an excellent option.... This industrial sewing machine is lighter than the previous model - it weighs no more than 33.5 kg assembly. Its volume is 0.077 cubic meters. m.

Like the previous version, the GC 6850 H has only one working needle, the stitches are made using the hook, and the material is advanced from the bottom. But there is also an important difference: the design is already designed for medium and dense textile materials.

Other properties are as follows:

- straight line execution;

- suitability for working with cotton, knitwear and artificial fibrous materials;

- automatic lubrication supply;

- minimization of noise and vibration even at high speed;

- sewing speed - 3500 stitches per minute;

- the height of the presser foot - from 6 to 13 mm;

- stitch length - up to 7 mm;

- the possibility of equipping with motors with operating voltages of 220 and 380 V (at the choice of the consumer).

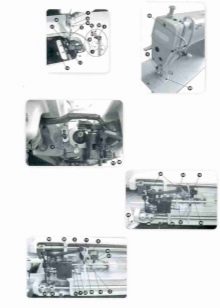

As for the modification DN 794, then it is not in the official assortment - but there is GN 794. This industrial 4-thread type overlocker can produce 5500-6000 revolutions per minute. The speed developed is determined by how dense the material needs to be processed. It is recommended to use GN 794 for sewing moderately dense to lightweight fabrics. The designers were able to implement such a wonderful option as a differentiated supply of matter.

The GC 6150 H is also noteworthy. This is a single-needle sewing machine with a total weight of 35 kg. Its total volume reaches 0.089 cubic meters. m. The shuttle and the lower material feeder are used for work. The machine can sew at 3500 rpm by raising the foot 6-13 mm and stitching up to 7 mm in length.

The 3-thread thread is very popular. overlock model GN 1-1D. This is a tried and tested craft model. Its design is optimized for use in ateliers, workshops and small sewing companies. You can put the car on any table. It will handle both moderately dense and very tough materials; proprietary drip lubrication technology has been implemented, which can also be considered an advantage.

The presser foot is raised by 4 mm if necessary. Needle standard is DCx1... The seam overlock can overcast from 1.5 to 3.5 mm. The system will sew 3000 stitches per minute. Two-strip overcasting is possible at the same time.

Another good overlocker is the GN 795 D. This is an industrial grade 5-thread model with internal drive. As stated in the description, the model is assembled in full accordance with Japanese technological requirements. It can be used to sew overlock seams. Sewing on light to medium materials is compatible with the trim to edge mode.

Operator actions are greatly simplified by built-in LED lamps. You can use two needles for sewing at the same time. Therefore, stitching and overcasting occur in parallel. After removing one of the needles, the apparatus switches to the mode of a typical three-thread overlock. The stitch length can be up to 3.6mm.

The ergonomic internal regulator helps to vary it. This regulator is placed on the side of the device. Overcasting is done in stripes up to 5 mm wide. Centralized automatic oil supply allows you to get rid of this tedious task.

GN 795 D is suitable for sewing guipure, flannel, calico, poplin at sewing speeds up to 5500 strokes per minute.

Reviews and recommendations for choosing

According to consumer estimates, Typical equipment has been working very reliably for many years. Only after being transported to a new location is sometimes a minor setup from scratch required. Neither overlocks nor sewing machines of this brand cause any complaints. The number of threads processed simultaneously does not significantly affect the rest of the practical characteristics and quality of work.

A positive feature of the Typical brand is the availability of many branded accessories. It is noted that many machines can work with jeans, fabric for covers, umbrellas. The only exception, which sometimes causes criticism, is the rare cases of factory defects. It is also worth remembering that imitation of a hand stitch is very unsuccessful on some models... The equipment works quite reliably within the warranty period.

It is also important to know how to choose the right model. Sewing machines with 1 or 2 working needles are suitable for sewing in zippers. To work with sleeves, shoes and other bulky items, you need to give preference to column-type machines. The choice of stitching machines when you need to work with blind edges.

The selection of a modification is determined by:

- its functionality;

- productivity;

- the composition of the processed fabrics;

- design features;

- power consumption;

- additional equipment of each device.

User manual

After manufacturing, 100% of machines and overlocks are stress tested. Therefore, consumers must themselves assess whether individual parts have been unscrewed, whether parts of sewing equipment have been deformed. Only special grade oil can be used for lubrication. Do not add too much lubricant to the system. During the running-in process, the machine is first started at minimum speed, and then only, with complete success, can the equipment be accelerated to full speed.

The pulley must rotate in a strictly defined direction. If not:

- the machine is stopped;

- disconnect it from the mains;

- turn the plug 180 degrees;

- put it back in.

If the machine sews uneven stitches, you need to adjust the tension and attraction of the thread. But the reasons can also be in the low quality of the thread or in the wrong selection of it. If oil is leaking, it is necessary to check its level and clean the special filter, as well as special passages. It is strictly forbidden to leave the plugged-in sewing machine unattended. It is also unacceptable to trust it to those people who do not understand this type of technology.

If the machine is equipped with a built-in backlight, you can change the bulbs or check their serviceability only after disconnecting from the mains. Only bulbs of the same type can be used for replacement. The same rule applies to all other details, of course. When water gets inside or there are incomprehensible problems, difficulties during work, you should immediately contact a professional service department. There are a few more security requirements:

- do not use a typewriter or Typical overlock outdoors;

- do not use them in wet or corrosive places;

- do not use this technique for anything other than the sewing work itself;

- do not put or use it where they work with aerosol spraying, with pure oxygen, with other flammable and easily flammable, explosive substances;

- do not make any changes to the design of the sewing machine;

- use only serviceable needles and other accessories;

- if possible, avoid dropping or wetting the machine;

- change needles, remove covers, perform maintenance, change or remove grease, bobbin, presser foot only after disconnecting;

- Do not use Typical toy cars as children's toys.

An overview of the Typical sewing machine is presented below.