Electric sewing machines

Mechanical sewing machines were replaced by electric ones. They have been successfully operating for decades, increasing labor productivity. Their operating speed is several times higher than that of purely mechanical sewing devices.

What it is?

Everyone is used to calling an electric sewing machine an electromechanical machine, but here only the motor that drives its mechanism is electric. Therefore, in what follows we will call it electromechanical. It differs from the electronic one in the absence of "advanced" functions. The device only performs the main work - so that the needle and shuttle parts move back and forth, passing the thread through the layers of fabric. At the same time, the fabric itself is advanced with the help of additional rollers, which make it possible not to sew one stitch on another, tangling and intertwining threads in the same place, but to line these stitches in one row, forming a regular and even seam. The productivity of labor on a typewriter, in comparison with completely manual sewing, can increase from dozens of times for beginner seamstresses to hundreds for experienced ones.

At the heart of the work of an electromechanical sewing machine is the replacement of the seamstress's efforts spent on the rotation of the drive wheel with kinetic energy received from the electric motor. The drive shaft, which used to be twisted by hand, using belts or gears, is connected to the motor shaft. Most often, the power supply to the engine is turned on via the foot pedal. It is possible to commute the motor of any of the legs by pressing the pedal. Thus, the seamstress has both hands to keep the seam flat as the seam comes out.

The electronic model has, for example, programmable modes to automate and speed up the embroidery process. And dozens of varieties of different seams are available here, allowing the seamstress to approach the most inaccessible places of the newly sewn or repaired product.

And one more difference. For example, with a broken needle or a loose sewing foot, a conventional sewing machine will try to continue working, not paying attention to the breakdown. In electronic, several sensors are responsible for a number of faults, simply blocking further user actions until the problem is eliminated.

An electronic typewriter can stop for a break, "noticing", for example, overheating of the engine or drive mechanism.

History

The appearance of the sewing machine goes back to the 18th century. Then they only copied hand stitch. In 1814, the Austrian tailor Josef Madersperger presented to the public a needle with an eye not at the base, but at a pointed end. Then Fisher, Gibbon, Walter Hunt, Elias Howe, and a number of other craftsmen set about developing an apparatus that could sew with such a needle. In 1830 Barthelemy Timonier patented the first installation, which significantly accelerated sewing with a needle with a hole near the point, and the first sewing workshop opened by him was in great demand.

In 1845, Elias Howe in America created a mechanism that could sew using a shuttle. The speed at that time was impressive - 300 needle cycles per minute. In this case, the needle made frictions horizontally, and not vertically, as in modern machines. Accordingly, the stitched strips of matter went vertically. A deviation of the seam from a straight line led to a stop of the mechanism, and a certain skill was required from the sewing workers.

In 1850 in the Wilson typewriter, and in 1851 in the Singer and Gibbs apparatus, the vertical stroke of the needle was adopted as the standard. The layers of fabric moved horizontally, adjusted by gears. Later, the gear was replaced with a plate with teeth. Further development was aimed at increasing the throughput of sewing machines.

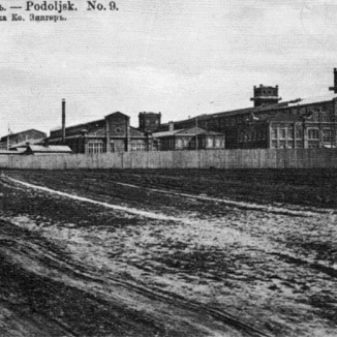

Singer sewing machines appeared in Russia at the beginning of the 20th century, and their production was mastered in Podolsk near Moscow. With the coming to power of the Bolsheviks and after the Civil War, the newly minted Soviet leadership renamed the Zinger plant into the PMZ im. Kirov ", and since 1923 the first Soviet sewing machines were produced under the brands" Gosshveimashina "and" PMZ ".

However, German developments continued to be used for more than a decade. Next came the brands "Podolsk" and "Chaika" based on this design. Experienced amateur craftsmen used self-installed AC motors instead of a crank with a drive wheel.

Today all these items are the property of antique collectors. They were replaced by modern compact electromechanical and electronic sewing machines, which simplify sewing and give the user a new level of comfort and several times faster operation speed.

The sewing machine allows you to turn the work of a seamstress from a hobby into a source of permanent income.

Views

A manual sewing machine is an already familiar unit in which the drive is rotated either by hand (using an additional transfer wheel equipped with a conventional "twist" like the one that is now put on a manual "dynamo" to charge batteries), or by means of a foot gear, rotation which is carried out with both feet. In the latter case, the foot pedal is put on levers that turn the shaft; the whole installation is located on a special sewing desk or table, and a belt will be pulled from the large wheel, wound on the drive wheel of the machine.

An electromechanical sewing machine differs from a manual sewing machine only in that the manual rotator is replaced by an electric motor operating from a standard alternating voltage of 220 volts. For commutation of the electric drive, a foot pedal is provided, which is pressed only by one of the legs, and not by both.

Experienced users converted Soviet typewriters using, for example, a Morse code telegraph key as a switch. Today the "ignition pedal" is supplied with such a machine - nothing needs to be altered. Switching modes is carried out using one or more buttons (toggle switches, switches or mini-levers).

Electronic sewing machines can contain either their own control board, in which their own firmware is "embedded", or they can be controlled by means of a PC or laptop. In both cases, cars have their own display, a row of buttons and switches. In the first case, the machine is able to cope on its own, having its own "firmware", which is "smart" enough to be able to use even the most "pretentious" mode. In the second case, the computerized sewing machine will not work on its own - it needs a third-party program from an external device.

The connection is via a USB-microUSB cable (like a smartphone or tablet). You can also adjust the working speed.

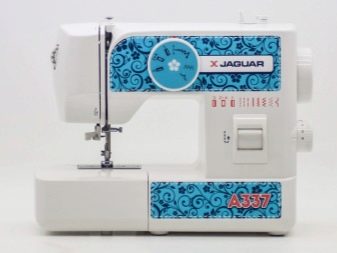

Manufacturers

Today, top manufacturers, starting with the most honored, are positioned as follows:

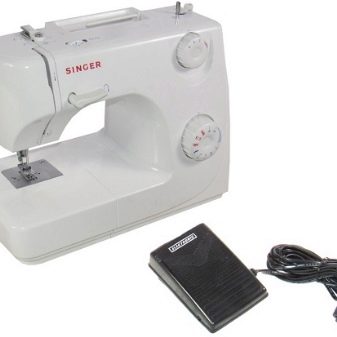

- Singer,

- Janome,

- Brother,

- New Home,

- BabyLock,

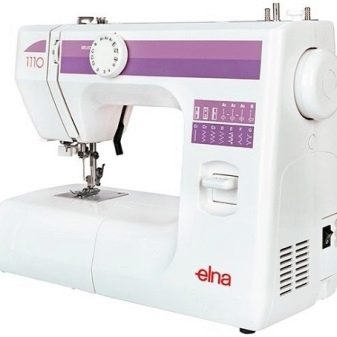

- Elna,

- Pfaff,

- Husqvarna,

- Bernina,

- Juki.

As the life of several generations of users has shown, the oldest of the brands to this day is considered the leader.

How to choose?

The final choice depends on the nature of the work - repairing clothes and accessories, perhaps simple sewing or ambitious plans and sewing truly beautiful things from scratch, perhaps creating an author's fashion for things, creativity, uniqueness. In the first case, an electromechanical machine will suit you - it has only the most common and simplest suture modes. In the second and third - electronic, with the ability to sew dozens of different seams in execution, up to the art of automatic embroidery.

How to use it correctly?

The rules for preparing and setting up the machine may vary. They depend on the type and specific model. Let's consider the general scheme of work.

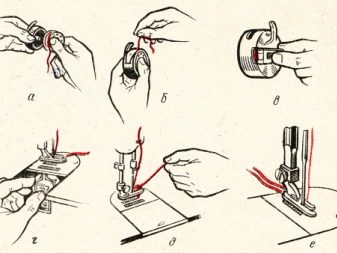

- Insert the needle into the sewing mechanism. The flat cut of the needle is turned to the rear.

- Wind the thread around the bobbin to the limit with the help of a special reel on the machine itself. Pull 10-15 cm of thread from the bobbin. Install and fix the bobbin at the bottom of the mechanism.

- Install the spool of thread onto the pin intended for it, unwind half a meter of thread and pass it through all the holes and hooks indicated in the instructions. Do not break this sequence. Thread the needle.

- Take both threads to the sidelifting the foot itself.

- Connect the pedal to the clipper. Plug the entire system into a power outlet.

Modern sewing machines can use the supplied power adapter. To check the quality of the sewing machine, insert test strips of fabric, select the desired stitch mode and try sewing (stitching) them.

Experiment with several types of seams. If the seams are straight, you can set the desired mode and start full-fledged sewing.

In the next video, you will find a review of the Janome MX55 electromechanical sewing machine.