Sewing machine needles: types and selection

Sewing needles are an important part of sewing and sewing-embroidery machines and undergo significant stress during operation. This obliges them to have high strength and excellent working qualities. The uninterrupted operation of the equipment and the quality of sewing depend on the technical characteristics of the needle, therefore, its choice must be approached very seriously and reasonably.

Description and structure

Sewing equipment needles come in a wide range and a wide variety of sizes and shapes. However, there are a number of features that are characteristic of all types of products, regardless of their narrow specialization.

Below are the main elements of sewing needles, which determine their purpose and performance.

- Flask the upper element of the rod is called, which is installed in the needle holder and is selected according to its size. By their shape, the flasks are flat and round. The former are intended for household samples, the latter for industrial units. Some rounded flasks have a recess for better fixation of the needle. It is on the flasks that the needle manufacturers apply the markings.

- Spearhead is located at the end of a needle and is pointed and rounded. The first is intended for working with dense, smooth fabrics and synthetics, the second is for coarse knits, lycra and thick denims. For heavier fabrics, a point with a left-hand groove is suitable to prevent thread breakage when the needle passes through the fabric.

- Chute (notch) is an important element of the needle and affects the quality of the buttonhole.

- Kernel represents the "body" of the needle and determines the piercing force of the tissue and the life of the needle.On one side, it ends with a tip, on the other, it goes into the flask.

- Needle eye located on the tip of the rod, it can be small or large. The size of the hole depends on the thickness of the needle and influences the choice of thread.

The inner surface of the eyelet is fairly smooth, preventing the thread from breaking and intertwining.

Varieties

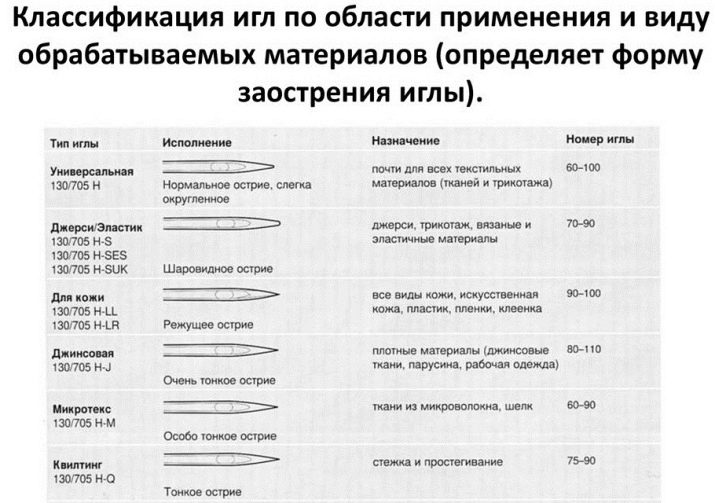

The classification of needles for sewing equipment is made according to their purpose and configuration. However, the second feature is a direct consequence of the first, therefore, the types of needles will be considered from the standpoint of the first criterion. So, each type of fabric has its own needle, which differs from other models in the shape of the cutting point. According to this indicator, there are tool with a sharp point for textiles and needles for leather goods. The tip of the former has a rounded shape and enters the fabric, piercing it through.

Below are the main types of needles used for woven fabrics of the textile group.

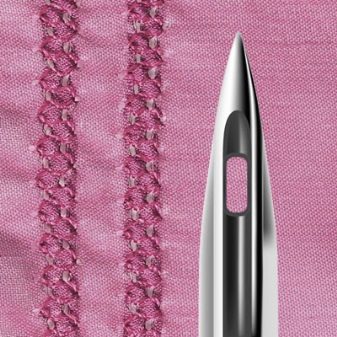

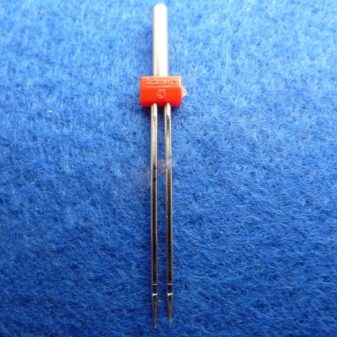

- Finishing stitching tools consist of two or three shafts, which allows you to form double and triple decorative seams, not experiencing heavy stress. These needles are indispensable when sewing patterns containing parallel elements.

True, they can not be used on all machines, but only on those that have the "zigzag" function and are equipped with a special slot in the stitch plate.

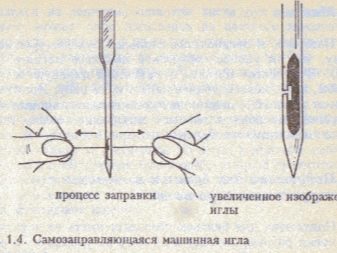

- Self-threading needles were designed for people who have difficulty threading their eyes. The shaft of these needles has a small slot that is flush with the eye of the needle. It is enough for a seamstress to pass a thread through it, moving it along the rod towards the point, after which it goes into the eyelet on its own.

- Knitwear needles have a spherical point, which is able to push the fibers of the fabric apart without piercing it... With the help of such needles, it becomes possible to form a smooth, beautiful line that does not violate the integrity of the canvas. This, in turn, excludes the appearance of arrows extending in different directions from the seam.

- Winged needles are designed to make decorative holes along the main seam, which leads to the formation of openwork stitches and hemstitching. The wings spread the fibers and leave small neat holes.

- The point of needles for sewing leather products is made in the form of a blade that does not pierce, but cuts through the material. This design of the tip allows you to work with all types of leather, including rough leather, which has a fairly large thickness. These needles practically do not break, do not skip stitches, do not break the thread and provide excellent sewing quality. The high strength of the material of manufacture and the well-thought-out shape of the point make it possible to use such models for a long time and with high sewing intensity.

A characteristic feature of the use of needles with a cutting point is a seam with a slight incline of the stitches to the left or right.

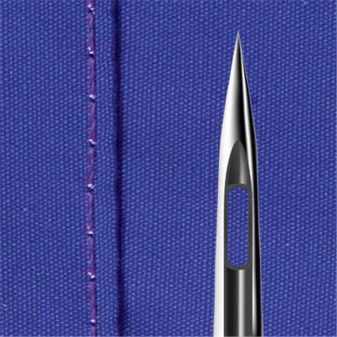

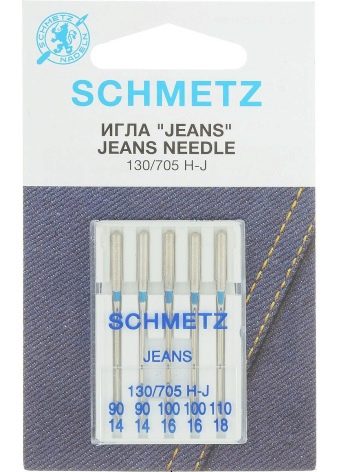

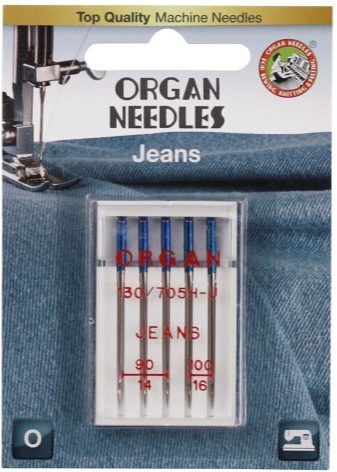

- Jeans needles are made using titanium-nitride sputtering technology, which in its strength is significantly superior to many carbide metals. Thanks to this coating, "denim" needles are distinguished by high wear resistance and long service life. The point of such needles is very thin, slightly rounded at the end, which completely eliminates the risk of damaging the fabric and skipping a stitch. It is very difficult to break such a needle due to the modified shape of the rod. In the past, tools often broke as they passed through the seams, causing legitimate consumer dissatisfaction.

After frequent complaints from factories, manufacturers have supplemented the rods with a cross-section of the grooves. This endowed them with increased resistance to bending, 20-40% higher than that of standard needles.

Letter designations

Sewing needles are available on the market in a huge assortment and differ in the parameters of the grooves, the shape and size of the eyelet, the way of sharpening, the configuration of the point and specialization in one or another fabric. In order to make it easier for the consumer to navigate in a wide variety of models, markings are applied to each needle.

In addition to numbers, the marking of the needles also includes alphabetic values that indicate for which materials this or that model is intended.

- H-ZWI mark is placed on double models, united by a single needle holder. The needles are produced in three numbers - 70, 80 and 90 and have different distances between themselves, which are also prescribed in the marking and indicated in millimeters. Typically, it is between 1.6 and 6.0 mm, while the 4 and 6 mm models are designed for straight stitching only.

- Letter character H-DRI It is placed on triple needles, which are available in only two sizes - 2.5 and 3.0.

- Topstitch needles are intended for sewing with loose decorative threads, have a wide eyelet and a special groove that facilitates the passage of unruly threads through the eyelet. The needles are equally well suited for both light and heavy fabrics and are available in sizes 80-100.

- Designation H-EM for embroidery with metallic threads. They are equipped with a large, polished eyelet and a groove to prevent thread delamination.

- H-SUK symbol Placed on models with a rounded tip. Such needles easily move apart the threads of matter, slip between them and do not damage the fibers. They are ideal for sewing heavy knitwear, knitted fabrics and jersey.

- Tools for sewing leather goods are indicated by the symbols H-LL and H-LR. They have a cutting edge and cut the leather at a 45 degree angle to the direction of the stitching. The result is a nice, neat seam with a slight stitch pitch.

- Letters H-O needles with blades are designated, they are designed for the execution of decorative stitches. Such models have a different blade span, which can be located both on one side and on both.

- Coding H-S affixed to models for elastic fabrics and not very dense knitwear. They are equipped with a special hem that prevents skipped stitches when the fabric is stretched while sewing. The tip of such a tool has a rounded shape, due to which it gently pushes the fibers of the material apart without disturbing its structure.

- H-J marks a sharp tool designed for working with thick fabrics such as denim, twill and tarpaulin.

- Designation H-M It is placed on microtex needles, designed to work with microfiber and rather thin materials of increased density, such as silk, taffeta and raincoat fabric. These needles are distinguished by a very thin and sharp shaft, which allows precise and rather accurate punctures to be made without pulling the tissue adjacent to the puncture site.

- Letters H-Q quilting needles with a bevel, a small eyelet and a rounded tip are indicated. This design protects the fabric from the appearance of large holes, eliminating skipped stitches. The tool has a narrow specialization and is used to form decorative stitches.

- Symbol H-E designates needles for embroidery that have a small eye and a slightly rounded point. Moreover, they are equipped with a special notch to prevent damage to the material and threads. Such a tool is designed for specialized embroidery threads; such needles are not suitable for working with ordinary sewing threads.

- Symbol H denotes universal tools with a slightly rounded point and intended for docile fabrics such as cotton, calico and linen.

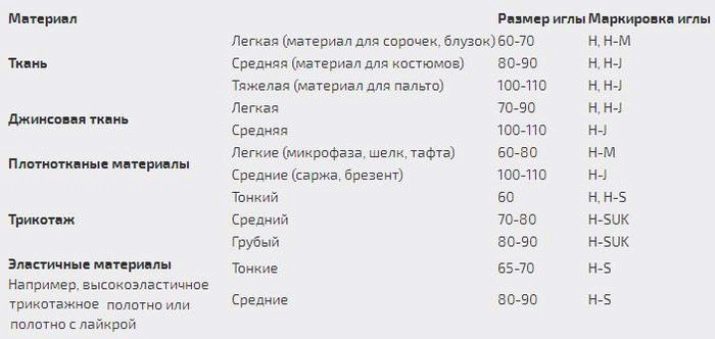

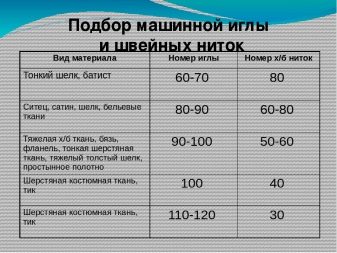

For greater clarity, a table is presented below that tells in detail what types and sizes of tools are suitable for a particular matter.

Digital marking

Numeric characters are usually affixed to the flasks and may look, for example, like this: 80/12. The first number indicates the diameter of the needle according to the European system of measurements and is indicated in 1/100 millimeter. After some simple calculations, you can see that the diameter of this needle is 0.8 mm. The second number also means the diameter of the tool, but this time in the American metric system, indicating a fraction of an inch.

The lower both numbers are, the thinner the tool. For household sewing machines, models with the numbering 60 / 8-120 / 19 are more often used, while the marking of the thickest copy is 200/25, and the thinnest one is 50/5. It should be noted that not all manufacturers indicate the diameter of the needle in two metric systems and it is not uncommon to see a tool on which there is only a European designation, for example, No. 60 or No. 120 (which means 0.6 mm and 1.2 mm, respectively).

The choice of the right size depends on the fabric you are going to work with:

- for extra-heavy fabrics, such as canvas and tarpaulin, take needles with a number from 100 to 200, taking into account not only the thickness, but also the density of the material;

- needle # 120 is suitable for cloth, beaver and burlap;

- it is better to sew heavy woolen fabrics with needles number 110;

- when sewing light wool, heavy synthetics and jeans, it is better to take a needle No. 100;

- clothes made of fabrics such as calico, crepe de chine, cambric and suiting fabric are sewn with needles numbered 80-90;

- fabric for shirts and blouses should be sewn with tool No. 60-70;

- for fabrics with lycra or thin jersey it is recommended to use needles no. 65-90.

How to choose?

In order to correctly select the tool for the sewing machine, there are a number of important points to consider.

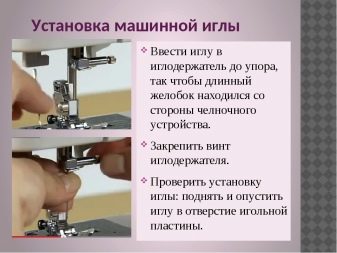

- If the models are bought for a household sample, then you should choose copies with a flat bulb. They fit easily into holders and fit very well. There are also specimens with a flat - a cut of the flask, which facilitates the correct installation of the needle when replacing it. An incorrectly selected bulb can lead to serious malfunctions due to the incorrect working position of the needle eye and point relative to the hook.

- The most common tools for household typewriters are the Organ 130 / 705H models. They have a slightly rounded point, come in a variety of sizes, fit most fabrics and are considered versatile.

- Experienced craftsmen recommend buying needles not one by one, but immediately in sets. This eliminates the need to go to the store when sewing distressed fabrics, as most kits include needles for all types of fabrics.

- An important criterion for choosing a sewing tool is the characteristics of the fabric. In order to find the right model, you should be guided by the table, not relying on the opinion of other people.

- If the tools are purchased for an industrial-grade unit, then models with a round flask should be chosen. In this case, special attention should be paid to the manufacturer. The best and most durable are the products of the German companies Grotz-Beckert, Schmetz and Organ Needles, which have been on the market for a long time and value their reputation.

- The type of sewing machine should also be taken into account, carefully reading the instructions for its operation. Usually, manufacturers tell in detail which needle numbers to use for sewing different fabrics, give an example of their marking.

- Long-term or improper storage can cause the instruments to rust. The use of such copies is strictly prohibited, as they can spoil the material and break the thread.

- When buying needles, you must carefully examine them. - if you find a curvature of at least one of them, you should refuse to buy a set. It will not be possible to align it under any circumstances, and you can easily ruin the fabric and damage the machine.

And you should also check the models for defects - poor sharpening and incorrect location of the groove in relation to the lug.

Experienced craftsmen and most sewing equipment manufacturers recommend changing the needles after every 12 hours of continuous use... If this is not done on time, then the needle begins to tear the thread and spoil the material, which in the end will cost much more than its timely replacement.

For information on how to choose sewing machine needles, see the next video.