Sewing machine lamps: varieties, selection recommendations

You have to work at the sewing machine very often in the dark or at dusk. And even on bright days, ordinary illumination is often not enough. This is why it is important to use a sewing machine lamp and choose the right one.

Peculiarities

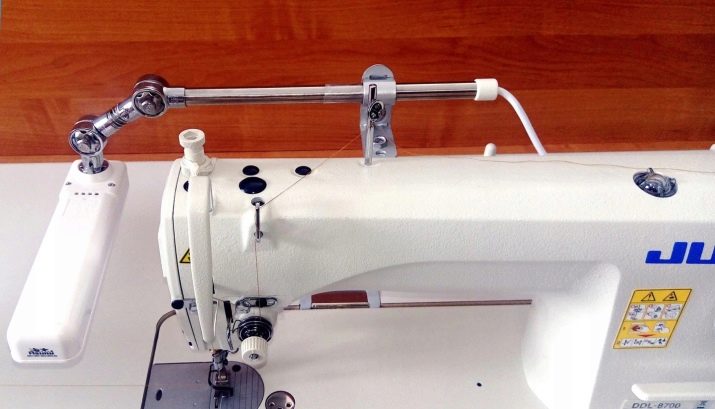

Lighting equipment improves illumination of the work area and minimizes eye strain. Anyone who has worked at least an hour on a sewing machine without additional illumination knows how tiring it is. Additional lighting is of particular relevance for visually impaired users. In modern versions, the luminaires are mounted on a table or built into the body. Therefore, there is no need for additional lamps.

Main types

The last generation typewriter bulbs are universal in design. They are equally suitable for all brands of sewing machines and overlockers. High quality light source compatible with sewing equipment:

- Brother;

- Janome;

- Plaff;

- Husqvarna;

- Elna;

- New Home;

- Singer.

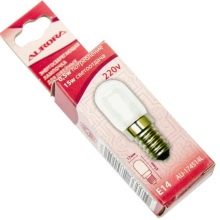

Similar bulbs can be used in refrigerators and other household appliances. They are often used interchangeably. Most often, you can find an incandescent lamp with a screw-shaped base. These models of bulbs are sold at any hardware store. Their power is 15 watts. The threads are formed in such a way as to guarantee compatibility with any chuck. The difference applies only to the height of the flasks and plinths. 2-pin bulbs are also used quite often. Their base is not covered with carvings. The power is the same as that of the screw counterparts.

The special structure of a 2-pin device sometimes makes it difficult to use. Many people cannot immediately insert such a light bulb correctly into the proper socket.It is not required to screw it into the chuck. It is only necessary to insert it inside, and then, after unfolding a ¼ turn, the contacts of the light bulb and the cartridge will be interlocked. Those who have already had to change the lamp in the car will immediately figure out what needs to be done.

2-pin models are completely versatile. The only difference between the two is the height of the bulb. Removing such a light source does not pose any particular problems. It is first pressed a little, and then turned. Do not make a lot of effort, otherwise the glass will collapse and cut your hands.

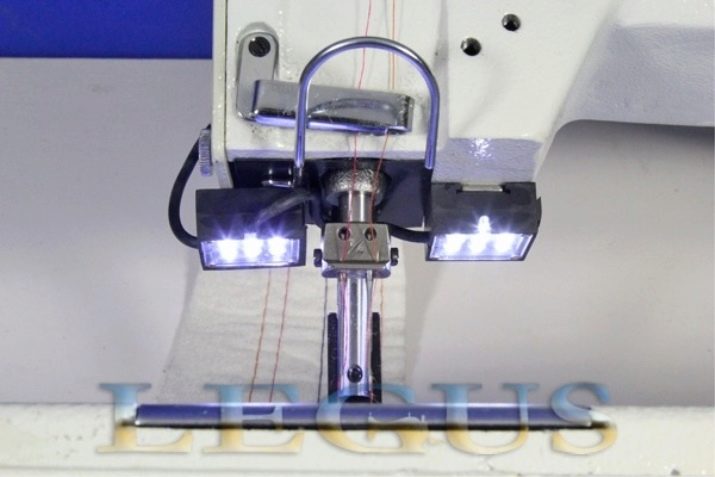

Some machines and overlocks may use LED lighting. This is a practical and modern solution. Often, instead of a conventional lamp, even a strip of LEDs is provided. A light source like this allows beams to be directed in a very targeted manner. Connoisseurs even note its convenience in everyday use.

Some LED luminaires do not require any special fixing at all. The base is magnetically fixed to the surface of the machine. Since almost all machines contain significant metal parts, there will be no installation problems. Even if it is a machine or an overlock of outdated models, which did not provide for a separate fixture of the lamp at all. LED and fluorescent luminaires last a long time and are not susceptible to filament breakage due to constant vibration.

Selection guide and usage tips

More and more companies are now abandoning screw bulbs. In the latest models, contact light sources are actively used. The problem is that outwardly it is completely impossible to distinguish them (we are talking about the lamps already put in place). A very practical solution is a lamp that can be connected directly to the starting unit of the sewing machine. As soon as it starts up, the backlighting starts automatically. At any stop, the lamp will extinguish in the same way in automatic mode.

The procedure for replacing a lamp or installing it from scratch is prescribed in the instructions for a sewing machine or overlock. Almost always, however, such manipulations will be required:

- de-energizing the device;

- removal of the plafond (grille, casing);

- scrolling the lamp by the flask against the clock;

- replacing it with one that is identical in size, voltage, type and power;

- performance check;

- return to place of protective elements.

If possible, you should always use LED bulbs. They compare favorably with even the best luminescent counterparts. The advantage is already evident in the fact that the optimum color temperature for sewing work is maintained. Flicker is completely excluded, which, albeit in a weak form, is present in any fluorescent lamp. It is very important to pay attention to the color temperature of the light source.

Magnetically mounted lamps are not very suitable for household sewing machines, usually with plastic housings.... They are better suited for professional equipment, which is a real powerful metal machine. Therefore, it is necessary to pay attention to the standard fixture of the lamp. Do not try to use magnetic lights on electronically controlled machines. The magnet can interfere with thin, highly sensitive microcircuits.

You can go to a sewing store for a suitable lamp. It is best to go where there are accessories for professional machines. But you can find suitable devices in most hardware stores where they sell tools. Large online stores, even from China, are another alternative. You should choose lamps there based on reviews and ratings.

For the household segment, side light is very important. It is provided with conventional table lamps. In this case, light sources with a warm yellow glow are practically unusable. They can look very nice to look at, but they are almost impossible to work with. At the other extreme, cold blue light not only damages vision, but also distorts colors.

The optimum color temperature is 5000 Kelvin. The deviation can be 200,300 units. Sellers do not always themselves understand what exactly they are selling, and where what is the real color temperature. Of specific models, it is worth recommending:

- Janome00009917;

- Hemline 131 M. LED;

- Aurora AU-205015;

- AU-174514LED.

Next, watch a video with tips on choosing bulbs for your sewing machine.

Lamps are now different everywhere. In Janome we have BA15D (220 V), Brother T10 W5W (9.5 V), other E14, latest models have LED elements, etc.