Why does the sewing machine skip stitches when sewing, and what should I do?

Like any device (even without electronic control), the sewing machine will skip stitches sooner or later. This problem is quite common, but it is not difficult to troubleshoot the problem. Why can the machine skip stitches when sewing and what should I do?

How are stitches formed?

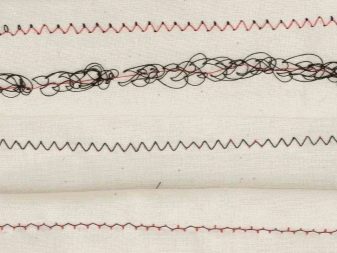

The line sewn with thread to fasten different parts of the fabric is generated when the needle and shuttle work together. The front end of the shuttle rushes towards the needle and pulls the thread loop from it. The hook then wraps the upper thread around itself and forms a stitch. The shuttle-based stapler is designed in such a way that if it is precisely adjusted, the stitches will certainly not be skipped even once. But over time, the details rub in, some of them begin to sag, sink in deeper than intended, and the sewing machine begins to skip stitches - at first, rarely and "by the piece", then it is already significantly "understitching" the seam.

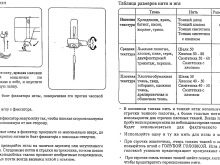

In fact, the distance between the tip of the needle and the hook is approximately 2 mm. For thin fabrics it is less than 2 mm, for thick fabrics it is slightly more. If you are not entirely sure which gap will be ideal, set it less (1.5 mm, for example), but not vice versa. The larger gap prevents the hook from catching the thread and it flies away from the needle.

The setting also depends on the stitching mode: for example, for a zigzag stitch, the setting is made in the extreme left and the same right position of the needle. Before starting the machine, always check the correct position of the pressure roller, the seam mode and the gap itself.

The main reasons for missing

Although a workshop specializing in the repair of such equipment can quickly and effectively correct the operation of a sewing machine with skipped stitches, the user does the simplest steps in troubleshooting on his own. The most common causes of skipped stitches when sewing are similar for sewing machines of all generations. - even for "Singer", even for modern models, including Chinese ones.

If we are talking about zigzag stitching, first of all they check whether the needle is not bent or blunt. This "occupational disease" is characteristic of beginners who forget to change the needle when switching, for example, from fleece to tarpaulin. If the needle is so dull that it is not able to pierce the fabric without tearing it at the point of the hole, and also if microcracks could appear in it, replace it immediately.

Wrong needle when sewing this or that fabric - a consequence of forgetfulness or inexperience of a novice worker. Despite the markings, externally, many sizes of needles are unusually similar. So, for knitwear, several blunt needles are used, which do not pierce or damage the adjacent fibers of the fabric, but push it apart. An attempt to use a needle that is too sharp can lead to loosening of individual fibers, near the seam, the fabric will wear out faster and give a stretch.

Each needle has a landing flask that fits into a reciprocating leg clamp. If you insert a round needle into this clamp instead of the cut one (or vice versa), then "aiming" into the gap where it goes with each stitch will change somewhat. In general, the mechanism will stop working with the accuracy for which it was originally designed.

- At best, the machine will sew inaccurately. The stitches will be crooked, offset along the same vector.

- The machine will skip stitches more often. - singly or in groups.

- If the needle catches too much on the presser foot or hook - it will immediately break down, and the mechanism of cheap cars, not being quite powerful, will receive noticeable damage.

The manufacturer indicates in the instructions and on the body of the machine the standard sizes of the needles - if the machine is not designed for sewing thick fabrics. Most machines are equipped with a double stapler, rather than a single (like most ultra-compact and portable) staplers. The upper thread in them is fed from the bobbin or bobbin from above, the lower thread from the bobbin or bobbin from the bottom, hidden under the presser foot. A thick needle should not be threaded with fine thread. It should not be too stiff - like, for example, Soviet cotton threads.

Better to use for example nylon option, which maintains the integrity of the weave, without crumbling when passing through the needle. Also, the thread should not be twisted from the factory - otherwise it easily forms twists that prevent the shuttle from regularly forming a loop. The ideal thread, according to consumers, should be smooth, not twisted, strong enough and elastic at the same time.

In the case of nylon threads, difficulties are possible: stitching inelastic fabrics can lead to skipped stitches and rupture of the newly created seam (before removing the fabric from the pressure mechanism of the machine).

The hole of the needle plate that is too widened in the process of work is a "disease" of machines that have been used for more than one generation. The broken hole does not allow the needle to pass through the fabric normally - it is punched into it, and the loop for stitching is not always formed or not formed at all. Poor fabric advancement under the pressure pieces can lead to both skipped stitches and overlapping stitches, which results in an intertwined seam. A more complicated version - the lower layers of the fabric move faster than the upper ones, which is why the latter wrinkle, the line acquires transcendental curvature.

Several types of fabric (leather and leatherette, nubuck, suede, corduroy, velvet) initially cannot move freely.To assist with the advancement of any of these types of fabric, a special foot with additional rollers is used to push these materials with noticeable force. By inserting the other foot with the Teflon layer, you can independently pull all several layers to be sewn into one. In a household sewing machine, "difficult" matter is difficult to process - for this, industrial, professional units are used, which use much more powerful mechanics, more massive needles and thick nylon as a thread.

Excessively slipping fabric will also cause skipped stitches. Having acquired a higher speed than intended, it prevents the shuttle and the needle from making a standard stitch in length. Uneven sliding can completely ruin the seam. All sewing machines have spring-loaded braces that provide tension on the upper thread. An overtightened tensioner, through which the thread is pulled with noticeable force, will cause skipped stitches.

If the thread is thin, and the mechanism is powerful, it will simply break. An overly loosened tensioner with a sagging thread can lead to tangled stitches, tangling and "knotting" of the thread. The seam will be damaged and the thread will break.

Remedies

The crooked line, of course, should be immediately unraveled and re-sewn. Even when the pieces of fabric are sewn securely, but unevenly, a crooked seam is left only in rare cases, when it is a rough, additional one. As a result, the finished product needs to be covered with a final layer. Defective, worn out needles should be replaced in time. First of all, when the machine is set up correctly, and the mechanism is in good order, the needle is pulled out and carefully examined for a broken eyelet, notches on the point and in its "body", base. A slightly bent needle can be straightened and used further. But a significant bend and chafing is already unforgivable here: the needle will continue to spoil both the seam itself and the fabric.

Replace HB threads with synthetics - they are smoother. Make sure to use artificial thread in both spools. HB threads are good only for hand sewing - and not with any fabric, but only with some of its types, for example, all with the same HB fabric.

Check if the gap is set correctly, if the correct foot is used in a particular case, if the correct seam type is selected. Make sure you are not stitching fabrics that the household stapler has difficulty pushing through or doesn’t push at all.

If the above reasons are eliminated, but the repetitive curved seam could not be corrected, urgent measures will be required: disassembly of the shuttle stapler and inspection, checking it for integrity. The drive itself may be malfunctioning - unstable speed due to wear on one or more parts. A decrease in the speed of mechanics is also possible due to the use of poor-quality lubricant, which over time turns into a viscous, like resin, stickiness. If you do not have experience in repairing mechanisms and devices, then repairing a typewriter will require a call to a master.

For electronic models, which are controlled using several or more buttons from the panel (or remote control), the reason may be a software failure, partial or complete failure of the control board. In this case, a full-fledged diagnosis is required. A faulty electronic board can be flashed again - at the level of its firmware. The faulty one is replaced with a new one - exactly the same or similar, from a compatible model of the machine.

Prevention methods

In addition to timely changing worn-out needles, changing threads and checking the mechanical setting of the machine, prevention consists in the timely cleaning and lubrication of rubbing parts in contact with each other. Most often, industrial machine oil is used as a lubricant, which, in addition to sewing machines, is used to lubricate hinges, door locks, various gear mechanisms and gears made of metal and plastic - like those that are used, for example,in a tall standing clock.

If there is no such oil in the kit (in Soviet cars it was necessarily supplied), you can try, for example, graphite grease or grease, lithol, engine oil, as well as the WD-40 composition used by cyclists to lubricate chains and sprockets. Do not overdo it - excess oil or grease at the first start will splatter all the insides in the lubrication area.

If the machine uses a belt-driven mechanism, check the serviceability of the rubber drive belts. Stretched, cracked, shrunken belts need to be replaced immediately.

Never use edible oils and fats - they evaporate faster, and you will soon disassemble the machine due to the lubrication of the parts. Before lubricating, be sure to clean the parts from black deposits formed by used oil, dust and particles of metal powder scraping off the gears. Do not "run" the sewing machine for many hours and non-stop at maximum speed when sewing hard and dense fabrics in several or more layers. In addition to the engine, the rest of the mechanics can overheat, which leads to the drying out of the same lubricant, premature wear of parts.

Even if in front of you is a typewriter of Soviet years, pre-war years of production, inherited from your grandmother, no matter how strong the steel and reliable engine are, such equipment is afraid of daily and many hours of "shock" loads. Since this is a home model for occasional or regular but not permanent use, it is unlikely to keep up with this rhythm.

When the hostess (seamstress) works as a “homeworker”, making custom-made items of clothing and accessories every day, she will immediately buy a semi-professional model. Such machines are close to the conditions of the "sewing" shop and are designed for daily, shift work, and not one-time work for half an hour or an hour once a week or month.

See below for what to do if the sewing machine skips stitches.