Embroidery machines: description of types and features of choice

Embroidery machines are a necessary and useful invention and are in high demand among needlewomen and craftsmen who sew and repair clothes. The high popularity of the equipment is due to its ease of use and great functionality.

Main characteristics

Embroidery machines are sophisticated automated machines that allow you to apply a pattern of any complexity to the fabric. Most of the samples are equipped with software, which allows you to load a sketch of the image into the device's memory, after which the machine automatically transfers it to the canvas.

For preview and correction of the position of the pattern on the fabric, the machines have a touchscreen display with a viewing angle of 180 degrees. Each line is clearly visible on the screen in real scale, which allows fully control the embroidery process and greatly simplifies the work of the machine operator.

The machines are capable of embroidering any image using overcast, elastic and blind stitches.

Each machine is equipped with a stretching hoop, which is attached to the machine platform on one or both sides. More modern designs are equipped with built-in needle threader and needle position switches. Most models have an automatic slider that adjusts the sewing speed. The machine will automatically cut its speed when sewing long stitches, which will keep the threads more even and improve the quality of the embroidery.

The most modern designs are equipped with a thread trimming button, after pressing which, the upper and lower threads are instantly cut without the use of scissors.This allows you to go directly to the embroidery of the next fragment, which is very convenient for production on an industrial scale. An equally convenient additional function is start-stop button, which will prevent the machine from starting when the foot is raised or the hoop is not installed. The indicator light will remain solid red until the error is cleared.

The principle of operation of embroidery machines is quite simple and consists in the following: after the operator fixes the fabric in the hoop, the carriage begins to move about two axes, and the needles located on it make punctures in the places determined by the program in accordance with the pattern. Most modern professional models are able to work with all types of thread and material of any density, and some of them can even embroider on felt boots. The machines are capable of embroidering in all known techniques: satin stitch, cross and half-cross, as well as cutwork, patchwork and quilling.

Due to the presence of computer support, the units can embroider large batches of patterns of the same type, which makes them an indispensable type of equipment in sewing shops and other light industry facilities. Full automation of the process of professional samples allows you to significantly reduce the number of labor in enterprises, which ultimately leads to a decrease in the cost of products. The operator only needs to set the threads of the desired colors and set the program. Next, the machine itself will choose the desired color according to the sketch uploaded to the computer and will change the order of using the threads according to the scheme proposed by the program.

Simpler machines for home use are capable of working with only one thread and need a human presence. The operator has to control the performance of embroidery, first with threads of one color, then, at the request of the computer, thread a thread of a different color and monitor the embroidery of the next element.

In addition, household samples are not equipped with a thread cutter, which is why the operator must independently remove the threads and cut off too long broaches from the wrong side.

Species overview

There are several types of embroidery machines: household, industrial and semi-professional.

Household

This type of embroidery equipment is presented single-head machines designed for decorating clothes and textiles at home. Household units are subdivided into embroidery and sewing and embroidery. The former are designed exclusively for embroidery, while the latter are capable of working like a regular sewing machine. The size of the hoops on such machines usually does not exceed 30x18 cm, and the motor life is much lower than on semi-professional and industrial designs.

The advantages of home machine tools are their affordable cost and ease of use. The disadvantages include the impossibility of refueling several colors at once and the need for constant monitoring of the machine's operation.

Industrial

These devices are represented by one-, two- and multi-head machines. By their functionality, they are divided into universal and highly specialized samples. And if the former are capable of performing any operations of various levels of complexity, the latter are intended for one of them, for example, for a chain stitch or embroidery of logos on chevrons. Most industrial models are compatible with additional equipment, which significantly increases their functionality.

All industrial units are different high reliability, large working surface area and increased service life. The latter quality allows the equipment to be operated in two or even three shifts with minimal interruptions for maintenance.

Semi-professional

Such machines are the most common type of embroidery technique and are used by both housewives and craftsmen in sewing shops and ateliers. Compared to clippers for home use these units are endowed with great functionality and have a high level of automation. This relieves staff from continuous monitoring of the machine and frees up labor for other operations. Most of the samples are fully compatible with various types of additional equipment, have a high sewing speed and are much cheaper than industrial analogues.

With their help, you can not only embroider in the classical way, but also sew on sequins, embroider with a cord, and also work in the boring technique (cutwork and cut-out stitch).

More modern designs have a large number of accessories.such as LCD backlight, thread cutter, stop-start button, automatic feed cutter, large built-in memory, self-threading device, sketch zoom function, end-of-thread sensor and needle speed control. The presence of a large number of convenient options makes semi-professional machines very convenient and comfortable to use, which significantly increases their popularity among small businesses.

What kind of thread and needles are suitable?

The quality of embroidery on an embroidery machine is largely determined by the correct selection of threads and needles. If there is an obvious discrepancy between the thread thickness and the type of fabric and needle size, the stitches will be uneven and ugly. Moreover, improperly selected threads can cause them to permanently break.

Usually, a table of thread thickness and needle sizes is given in the accompanying documentation for the machine, but if the instructions are lost or missing, then you can use the general rules for choosing threads. It should be noted right away that Embroidery threads are different from ordinary sewing threads and have a different density and fiber structure.

In this regard, it is only necessary to fill the machine with special embroidery threads and do not use sewing. Below are the main types of embroidery thread and their characteristics.

- Viscose yarns are of artificial origin and indicated by marking Viscose or Rayon... The most famous manufacturer of viscose products is the company Madeira... These yarns are soft and shiny and come in a wide range of colors and sizes. They adhere well to fabrics, do not form loops and are highly resistant to wet and dry cleaning.

- Polyester threads also have a synthetic base and are indicated by the icon Polyester... They are distinguished by a beautiful and even shine, although there are also matte options among them, which are designated as Frosted Matt... Such threads are much stronger and more elastic than viscose threads and are much cheaper. Clothes with polyester embroidery can be bleached by any means without damaging the thread structure.

Among the disadvantages of polyester threads are the tendency to form loops and possible deformation of the pattern some time after embroidery.

- Cotton thread characterized by a matte surface and lack of gloss. Cotton does not tolerate bleaching and contaminates equipment with the smallest cotton dust, which is not typical for synthetic threads. Among the minuses, one can also note limited color gamut, as well as a somewhat rustic appearance of the finished embroidery. The advantages include low cost and no tendency to form loops.

- Metallized thread has a beautiful gloss and poor flexibility. It is capable of causing significant damage to equipment and is designed to operate exclusively at low speeds. Besides, metallized threads do not tolerate bleaching and are not suitable for all fabrics.

When choosing threads for an embroidery machine, you should pay attention to their thickness. The best option is the size # 40, and the number has a feedback with the thickness. So, the thicker the thread, the lower the numerical index it is designated, and vice versa - thin threads have a higher number.It should also take into account the fact that threads of the same size, but of different composition, visually differ in thickness.

For the upper thread, numbers 40-60 are usually used, and for the lower thread, between 80 and 200. However, in this matter, everything is very individual and depends on the material and setting of the machine. Often the machine begins to tear the thinner thread, which is why it has to be changed to a thicker one. The thicker the bobbin thread, the more difficult it is to adjust the upper thread and the more often you need to change the bobbin., but the embroidery is denser and more attractive. Experienced embroiderers believe that number 80 is the best choice for the lower thread.

As for the manufacturers of threads for embroidery machines, the products of the companies have a large number of positive reviews. RainBow and Gunold... Their threads are produced in a wide assortment, they get along well with delicate fabrics and "are friends" with the upper thread. When choosing threads, professionals recommend paying more attention not to their thickness, but to the density, since a thin-looking thread often has a very high density and vice versa.

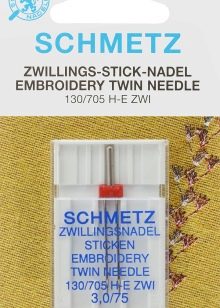

When choosing needles, it is necessary to consider so that their size corresponds to the thickness of the threads. For example, when embroidering on light fabrics with cotton threads # 80-100 or polyester threads # 60-80, a needle size 9-11 (70-80) is suitable. To work on medium-sized fabrics using cotton thread # 50-80 or polyester thread # 50, you need a needle # 11-14 (80-90).

Heavy fabrics are embroidered with cotton thread # 40-50 or polyester thread # 50, using needles # 14-16 (90-100).

Manufacturers

The modern sewing equipment market offers a huge selection of embroidery machines from well-known manufacturers. Below is a rating of the most popular samples that occupy the first lines of popularity according to the version of online stores.

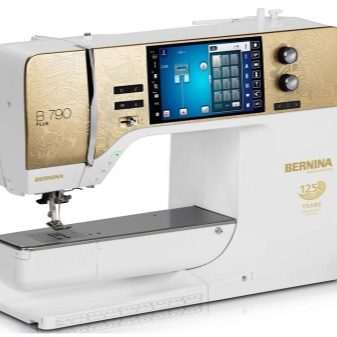

Bernina

A company from Switzerland is considered a leading manufacturer of sewing and embroidery equipment and is the only manufacturer of equipment that has retained its production in Europe. The semi-professional model is very popular Bernina Aurora 450, designed not only for embroidery, but also for sewing. The model is equipped with the most modern software and has 163 sewing programs.

More than 400 different images and four sewing alphabets are stored in the memory of the machine, which allows it to be used for conveyor embroidery of chevrons and logos. The machine is equipped with a movable hoop with a working area of 25.5x25.5 cm and is capable of working at a speed of up to 900 stitches per minute. Additional options include scaling, mirroring and layout design. The unit is equipped with regulators of thread tension, foot lift and material puncture force, and the connection to a computer is carried out via a USB port. The cost of the car is 120,000 rubles.

Husqvarna

The Swedish company was founded in 1689 and is one of the oldest manufacturers of embroidery machines in the world. Its products are in high demand and are well known in our country. Among the semi-professional models, a sewing and embroidery machine can be noted Husqvarna Designer Topaz 50capable of performing 261 operations. The unit can make 9 types of loops and can handle absolutely all materials.

The size of the hoop is 36x20 and 12x12 cm, which allows making both large designs and small chevron embroidery. New drawings are loaded using the USB port, there are options for editing and combining images, and there is also the possibility of mirroring thumbnails. The program includes 5 built-in alphabets and a sewing advisor function.

Sewing speed - 1,200 stitches per minute, cost - 155,000 rubles.

Velles

The Russian brand is well known both in our country and abroad. The company is engaged in the production of sewing and embroidery equipment and supplies to the domestic market reliable and modern designs. As an example, consider a single-head embroidery machine Velles VE 15C Next, designed for embroidery on all types of clothing, including hats. The model is compact and lightweight, which is why it can be installed in computer embroidery workshops and small ateliers.

The unit is capable of using up to 15 different colors, automatically switching between them according to the sketch. The maximum working speed is 1,000 stitches per minute, automatic needle change and thread trimming functions, and the machine can memorize 980,000 stitches or 99 patterns. The device is equipped with 12 hoops, among which there are both rectangular and round versions. Engine power - 400 W, product weight - 157 kg, cost - 340,000 rubles.

Tajima

Japanese industrial embroidery machine Tajima TSMH - 601 (460x550) S belongs to the category of expensive equipment and costs $ 16,000. This chainstitch model has no hook and chain stitch. A distinctive feature of such machines is the use of only one thread, which is why the drawing differs markedly from the image made on a conventional shuttle machine, and it turns out to be very voluminous and convex.

Embroidery on such machines is performed using soft and fluffy thread, and the chain stitch technique does not form a rigid backing on the seamy side. Due to the ability to create high terry stitching, the model ideal for decorating children's clothing with beautiful volumetric embroidery. The working speed is 650 stitches per minute, the needle adjustment has 10 positions, and the processor memory contains information about 10,000,000 stitches.

Happy Profi

Single head embroidery machine equipped with a touchscreen display (HCS2) and manufactured in Japan. The model belongs to the industrial class and is designed for intensive serial embroidery. Due to the presence of a large number of needles (12 pieces), the machine can embroider multicolor designs without spending time on manually changing threads. The speed of the unit is 1,000 stitches per minute. The machine is equipped with two types of hoops - rounded, 32x32 cm in size and round, 15 cm in diameter.

The weight of the product is 42 kg, the memory is 2,000,000 stitches or 250 images, the cost is 589,000 rubles.

Ricoma

Embroidery machine EM 1010 is a representative of the American brand and is very easy to use. The model is equipped with a built-in advisor function, thread break sensors, a carriage with ten needles, modern software and a touch screen. The size of the hoop is 36x20 cm, the embroidery speed is 1000 stitches per minute.

The machine memorizes 20,000,000 stitches and can embroider on caps. The model is well suited for small businesses for sewing and repairing clothes, as well as for computer embroidery workshops. The cost of the embroidery machine is 379,900 rubles.

Jack

Model CTF1201 designed for embroidery on hats, finished products, clothing, uniforms, chevrons and even shoes. The model is equipped with automatic thread trimming functions, remembers 99 patterns (1000 stitches) and weighs 145 kg. The product is equipped with three hoops, 2 of which measure 33x29 cm, and the third - 33x55 cm.

The machine is very reliable, sturdy and designed for continuous operation with short interruptions. The cost of the machine varies from 397,000 to 420,000, depending on the supplier.

Barudan

Japanese one-head embroidery machine BEVT-S901 CA is different light weight and compact size. The model is equipped with a servo drive, nine needles, practically does not make noise and is characterized by high quality of embroidery. The machine is equipped with a cord embroidery device, a boring device (cutwork technique), has a cylindrical frame and an oscillating shuttle.

The latter is intended for embroidery with woolen threads, which is not found in all models. When working with clothes, the machine can embroider at 1,200 stitches per minute, and when sewing baseball caps - up to 1,000 stitches per minute.The machine's memory capacity is 1,000,000 stitches, weight - 76 kg, cost - 900,000 rubles.

Brother

Sewing and embroidery budget model NV-90 E is different affordability and attractive design. The machine can make beautiful patterns on curtains, decorate clothes with embroidery and create logos. The machine has 70 built-in designs and 5 fonts, is equipped with a needle threader and a long cord.

The size of the hoop is 10x10 cm, the cost of the machine is 32,000 rubles.

How to choose?

When choosing an embroidery machine, you need to pay attention to a number of important points.

- First of all, you need to decide on the class of the product. For home use, household models costing up to 100,000 rubles are suitable, for an atelier or computer embroidery workshop, a two-head semi-professional model costing up to 300,000 rubles would be an ideal option, and an industrial design costing up to a million rubles would be needed for a tailoring workshop.

- Another important selection criterion is the size of the hoop. The maximum area of the working field depends on it, therefore, the size of the picture, the width of which will be limited by the length of the platform. The smallest hoops measuring 10x10 cm are installed on budget household models, while on powerful industrial designs their size exceeds 26x40 cm.

- If the machine is bought for a business, then you need to pay attention to the embroidery speed. Most semi-professional and industrial devices are capable of producing 1,000 or more stitches per minute, which is quite enough for mass production. The speed of household machines is much lower and reaches 400-500 stitches per minute.

- Attention should also be paid to the fixation of the tissue, which is the weak point of many machines with large rectangular hoops. This parameter determines how accurately the pattern will be applied and whether the stitches will not shift when embroidering. Especially often, sagging areas of tissue located at the maximum distance from the attachment suffer from image distortion. Therefore, the best option would be to purchase a model with an oval hoop.

Features of operation

Using the embroidery machine begin with the development of the design of the future imagewhat you can do on your home computer. Then the picture is edited and sent via USB-port, CD-disk or Wi-Fi to the machine's memory. Next, the drawing is projected onto the fabric, previously attached to the hoop, and placed in the desired place.

A built-in computer is responsible for the correct position of the sketch within the hoop, which allows you to rotate the design 360 degrees, as well as reduce or enlarge it. The system automatically divides patterns that are too large into several fragments, which are subsequently sewn in sequence.

In addition to correcting the image, the computer displays information on the operation of the machine and prompts the operator on which thread and needle to choose.

Many modern samples have video instructions in their memory, which show in detail how to correctly perform a particular operation. Usually, after viewing them, users have no questions about the operation of the machines, especially since in many designs the embroidery process is fully automated.

The exception is budget sewing and embroidery models that require manual threading, thread trimming and constant monitoring of the machine. After the pattern is corrected and projected onto the selected area of the fabric, the operator presses the "start" button and the machine starts embroidering. After the unit has done its work, the product is removed from the hoop and ironed with steam.

Advice

In order for machine embroidery to be beautiful and neat, it is necessary to take into account the advice of experienced craftsmen.

- If there are errors in the stitch, then the matter is most likely a mismatch between threads and fabric.

- If the stitches pull tightly on the fabric or the sewing machine starts to loop, the upper and lower threads may not be adjusted properly.

- The bobbin thread should always be either thinner than the top thread, or the same size as it. Otherwise, the upper thread will tear and tighten the fabric.

- When choosing needles, you should be guided by the quality of the fabric and the size of the threads. A needle that is too thick will leave unsightly holes in the fabric, while a needle that is too thin can break quickly.

- When machine embroidering large items, a stabilizer must be used. - non-woven material that is placed under the product or placed on top. This lining is especially useful when embroidering on terry cloth. It reliably holds the pile and prevents the loops of the fabric from penetrating the embroidery. As a stabilizer, special films with a water-soluble or thermally destructible texture are usually used, which are removed after the end of the work. However, in some cases, the nonwoven backing is left on the product where it provides support for the embroidery and helps to maintain the shape of the pattern.

For information on how to choose an embroidery machine, see the next video.