All about the profession instrumentation locksmith

All people more or less know who a locksmith is. However, it is equally important to know everything about the profession. instrumentation locksmith. This type of activity is little familiar to ordinary laymen, but deserves maximum attention.

What is this profession?

In various sources, you can read that the history of the profession of a locksmith goes back centuries. Already in the XV-XVII centuries, there were separate specialists of this kind. But the development of industry did not stop, and in the twentieth century, such a key specialization as instrumentation and automation fitter appeared. This is not the kind of employee who "goes everywhere with a wrench and tightens it up if necessary." This is a much more complex and sophisticated specialization.

Locksmith of instrumentation and automation (this is how the abbreviation for instrumentation and automation stands) must be of legal age. To occupy such a position, you will need average level of professional training least. The admission to the activity is made after medical examination. Additionally you need to master safety standards and requirements for the operation of electrical equipment. You will have to pass annually certification. Contraindications for working as a mechanic for instrumentation and automation are the same as for specialists at electrical installations with a voltage of 42 V. The industry celebration in Russia falls on December 22. The international holiday - more precisely, the day of the metrologist - was scheduled for May 20.

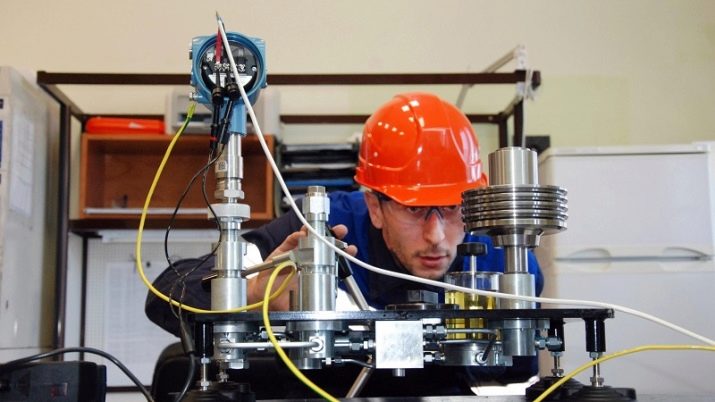

An instrumentation mechanic works with extremely "thin" mechanisms both in size and in sensitivity.He has to use tools of all sizes.

Job description and responsibilities

Appointment of an instrumentation locksmith to a service position and his removal is made by a written order of the head of the organization. This specialist:

- repairs, regulates, tunes and adjusts all kinds of equipment;

- assembles, tests, adjusts, calibrates automatic, heat measuring and electronic equipment;

- checks the performance of all types of electrical measuring devices, including reference devices;

- takes care of the operability of automatic units, including complex electronic components;

- conducts arbitration measurements;

- detects various problems and fixes them;

- determines the level of wear;

- corrects technological parameters of devices based on semiconductors and electronics, properties of integrated circuits;

- adjusts and tests new equipment;

- carries out the processing of the readings of the measuring equipment by mathematical methods (if necessary, using software packages);

- collects circuits.

But this is not the end of the range of duties of an instrumentation locksmith. This professional carries out the delivery of serviced technical communications on a turnkey basis, with the preparation of the necessary documents. It also works with mechanical, pyrometric devices, recorders and other devices. You will have to deal with the manipulation of parts in accordance with 11 and 12 grades and carry out proper debugging.

Another functionality of the instrumentation locksmith is:

- fitting parts;

- soldering with various solders;

- hardness testing using tared files;

- painting of working devices;

- repair and adjustment of especially complex devices (under the supervision of engineers or especially experienced mechanics of the highest category);

- checking the serviceability and operability of all entrusted equipment;

- compliance with fire safety rules;

- monitoring the health of interlocking and signaling systems, protective equipment, fences, grounding;

- constant use of protective equipment required in a particular case;

- maintaining elementary order.

ETKS discharges

The list of operations performed by instrumentation locksmiths may differ depending on their category. Those who receive the second grade can already process parts at the level of 12-14 grades. Also they will have to repair, adjust, test and hand over:

- simple;

- working on the principles of electromagnetism and magnetoelectrics;

- optical-mechanical;

- heat measuring devices and apparatuses.

A professional of this level should be able to to mount connections according to simplified schemes, as well as to wind springs from cold wire, to find and eliminate malfunctions of simple equipment. Second-level instrumentation and control mechanics perform protective lubrication of parts. They can repair moderately complex appliances under the guidance of a more experienced locksmith. Examples of their work:

- medium repair, adjustment of electrical equipment (primarily ammeters, galvanometers and manometers);

- processing of parts of scales of railway transport;

- repair of trading and auxiliary weights;

- preparation of transformer frames;

- a set of gear wheels with a futor;

- not too serious repair of magnetic contactors;

- assembly from ready-made sets of parts for technical pressure gauges;

- correction of the frame counter of a mechanical camera.

Instrumentation locksmiths can:

- overhaul and adjust ammeters, electric meters, gearboxes and gauge equipment;

- repair industrial scales;

- adjust and correct aneroid-type barometers;

- carry out current and urgent repairs of commodity, truck scales;

- pressurize hydraulic sensors;

- cut threads in blind parts;

- repair sensors based on the piezoacoustic effect.

Climbing up the rank, it's easy to see extended functionality. Such professionals can work with complex devices of various types, expertly adjust and finish their parts (assemblies). In case of locksmith's manipulations with parts, the quality of work corresponds to 7-10 qualifications. 4 grade locksmith gives him the right to configure and establish complexes of relay electrical protection, telemechanical and automatic complex systems.

Also, the privilege of this specialist will be the elaboration of complicated connecting circuits, the calculation of absolute (but also relative) errors when testing devices.

Locksmith of instrumentation and automation of the 5th category:

- makes equipment for laboratories;

- draws measuring scales, technical grids, makes complex sketches;

- recalculates electrical appliances for other limiting measurement characteristics;

- checks the compliance with the qualifications of various automatic regulators, automatic power supplies, adjusts as needed;

- repairs and adjusts automation that controls pressure and temperature parameters;

- mounts and adjusts wagon and truck scales;

- repairs goniometers;

- makes fine-tuning of optical parts;

- checks and repairs interferometers;

- repairs reference pressure gauges;

- evaluates the performance of universal microscopes, eliminates their defects.

The highest demands are predictably placed on instrumentation locksmiths 6th category. Such specialists can already work with radioactive devices, parts of radio stations, direction finding and radar systems. They need to possess not only metrological knowledge, but also information from telemechanics, heat engineering, radio engineering. A 6th grade instrumentation and automation fitter performs the following work:

- adjustment of electronic equipment;

- adjustment of operating autoregulators and heat metering systems;

- overhaul of automatic portion scales;

- any kind of manipulation with exemplary wagon scales;

- overhaul of gas analyzers, television meters, rangefinders;

- the most complex repair work with mechanical film cameras, photo cameras;

- installation of magnetic oxygen meters;

- repair of oscilloscopes, pyrometers, potentiometers, comparators.

Requirements for employees

Education

The very name of the profession suggests that its representatives should be perfectly familiar with modern automation and be ready to troubleshoot. Therefore, candidates are expected to secondary vocational education at least... Training at the level of not a technical school, but an advanced college is encouraged. The specific circle of training is determined by belonging to a particular industry. This, by the way, makes it very difficult even to draw up standard job descriptions.

One way or another, the instrumentation locksmith must skillfully apply (depending on the category):

- information on the structure and principles of operation of the serviced equipment;

- state standards;

- methods of thermal and mechanical treatment of parts of mechanisms;

- electrical and thermal mechanical circuits;

- the basic procedure for calculating the errors of devices;

- the procedure for calculating electrical resistances;

- fundamentals of telemechanics, radio control, programming of controllers, simple microcircuits.

Mandatory item in preparation for certification for any category there will be mastery of interbranch labor protection. This includes, first of all, the norms for the use of electrical installations and the principles of industrial safety.

You will also have to master the basic rules of working with the instrument.

For all disciplines, the results of certification are reflected in the protocols and qualification certificates. Additionally, in each commercial and state structure, of course, they are certified for compliance with job requirements and technological standards.

It is also highly desirable to know:

- key parameters of conductors and insulators;

- methods for measuring resistance;

- qualifications, information on technical roughness;

- oils and greases with corrosion inhibiting effect;

- key properties of metals and non-metallic materials required by industry;

- factors affecting distortions in the measurement process, causing inaccuracy of technological procedures;

- legend of various parts and their significant properties;

- systems of tolerances and landings;

- kinematic diagrams;

- features of interaction of sequentially or jointly used devices and apparatus.

Personal qualities

Of course, such an important role of instrumentation locksmiths in the industry requires them maximum responsibility. At the same time, they must very clearly perform even the smallest outwardly task. In addition to these qualities, it is extremely important:

- advanced technical and spatial thinking;

- speed of decision making;

- the ability to act clearly in a lack of information;

- rational distribution of attention;

- resistance to emotional influences;

- willingness to work alone, in large and small groups;

- the ability to concentrate even with strong interference.

Job prospects

Instrumentation specialists are needed for all industrial production... But most of all they are in demand in large firms that are constantly developing. The size of the salary is highly dependent on the specific region of employment and skill level.

Horizontal growth implies the sequential development of qualifying categories. Vertical - raising the general level of qualifications, with the transformation into a foreman or an engineer.

On average in Russia, locksmiths have an income of 20-50 thousand rubles... Becoming an engineer, you can count on wages from 30 to 80 thousand. The income of an instrumentation locksmith in the Trans-Baikal region (at certain ore objects) can exceed 200 thousand rubles.

In the regions of the Far North, when working on a rotational basis, one can apply for a salary in the region of 100-120 thousand. But it is important to understand that it is not so easy to get complex equipment working in a harsh climate.

Where to get training?

Admission to colleges and universities in the specialty "Control and measuring equipment" requires a compulsory examination in history and the Russian language. You will also have to pass a profile exam (physics or mathematics) for the mark "excellent". Distance education for these specializations is not practiced. Instrumentation locksmiths training programs are open in the following educational institutions:

- College of Modern Technologies (Moscow);

- technical school of space instrumentation (Moscow);

- Industrial and Technological College (St. Petersburg);

- Izhora College;

- a number of training centers.

In the regions of Russia, the same training is carried out:

- electromechanical college Cheboksary;

- Petrochemical College (Kazan);

- Law College of Chelyabinsk;

- industrial and economic college (Omsk);

- engineering college (Samara);

- chemical-technological college (Perm);

- Voronezh College of Welding and Industrial Technologies;

- technical school of welding technologies and power engineering (Krasnoyarsk);

- Tyumen College of Construction Industry and Municipal Economy.