All About Candle Molds

A candle shape is a kind of container, without which one or several candles of the shape you like cannot be cast. It gives the candles any design - the casting process is limited only by the master's imagination.

Description and purpose

In the simplest case, the candle shape is a polymer tube that can withstand heating up to more than 100 degrees.

It is at similar temperatures that wax and paraffin (stearin) melt.

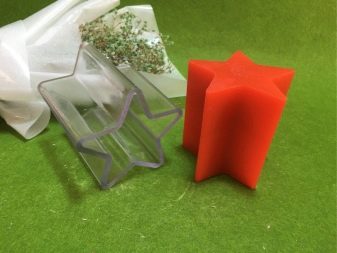

A slightly complicated version - a form, for example, in the form of a three-dimensional letter or number, breaks up into halves when the frozen content is removed. The general principle is the same - a hole is drilled on top through which wax or paraffin is poured. And there are also guides through which you can stretch a thread or thin string. Along it, during the combustion of the candle, paraffin, melted due to the proximity of the burning flame, is pulled up.

Species overview

Candle molds are classified according to the material from which they are made.

Plastic are the cheapest and most affordable. Most types of plastic melt at more than 200 degrees, this is a significant, double temperature margin when using the candle mold for its intended purpose. Plastic is easy to process, it is easy to get original, unusual outlines in the form of a rune, a pumpkin from it, twisted spirals and a cylinder are also available.

A variety of polymer forms are silicone.

Simple forms are cheap, but the more complex this form, the more expensive it is, the price can go up to 12 euros and more.

Some products are rough on the inside. - the candles cast in them acquire the same surface, only the other way around: the depressions on the inner surface of the mold become bulges of the cast product that are identical in size.

All forms are classified as plastic: from high density polyethylene, from PVC, PET, polycarbonate. PVC and polycarbonate can be easily washed from traces of the work just done.

The metal forms include brass, duralumin, aluminum and others. Aluminum is one of the cheapest and most common metals: it can be washed, but it is afraid of soda and soap. Aluminum molds are solid, without seams, which cannot be said, for example, about stainless steel or any other steel.

Glass molds are mainly made from tempered glass. The fact is that a simple non-tempered glass with a rapid (per second or less) change in temperature by at least a few tens of degrees will burst immediately: proof of this - pour boiling water into a wine glass or glass, and it will immediately crack. Paraffin wax melts at a similar temperature, which means that the glass must withstand this temperature drop.

Composite molds are considered a rarity, since they would cost at least several times more. Their use is justified only where it is necessary to emphasize the status of a particular institution. For example, in teahouses and cafes, decorative candles of unusual shapes are used in the form of a decanter, a relief cube, a female figure and much more.

For casting thin candles, for example, church ones, molds are used in the form of the same inner diameter of tubes. In general, for casting, you can also use a tempered glass test tube, tying, for example, a fishing sinker or a piece of technical solder to the lower end of the thread. For carved candles, for example, with spiral ribbing, reminiscent of the protrusions of building fittings, similar shapes are used.

Secrets of choice

The choice of molds for casting candles comes down to the following rules.

- First of all, decide on the appearance and diameter of the candles that you want to cast in a specific shape. If you want to emphasize the status of an institution, for example, a cafe, where there are such service functions as organizing a romantic dinner by candlelight, where there are secluded and closed booths for couples in love, then you should choose a shape that allows you to cast candles in the form of an elongated or rounded heart, the numbers “ 7 ", a cheerful gnome or troll. However, the list of ready-made forms is not limited here. Church wax candles, for example, in their manufacture are distinguished by a long and simple or corrugated look - secular pretentiousness is useless here.

- Having decided on the shape, carefully inspect the item for chips, cracks, burrs. A damaged shaped container will at least spoil the look of the cast candles; in the worst case, paraffin will spill during pouring, solidifying in cracks and holes of arbitrary shape. A cast candle will automatically receive all these defects; it will be difficult to remove it without damaging it.

- The color of the uniform does not matter. Wax or paraffin, dyed in a certain color, independently gives the desired look and design to cast candles. A non-specific application of metal molds is the casting of bitumen blanks for torches, but this is a completely different field of application of the candle mold.

Having chosen a molded product for casting candles, they proceed directly to the process itself.

Terms of use

Paraffin is melted from the stubs of old candles, or a new one is melted, and poured into a molded product using a ladle with a sharp nose.

Casting must be done quickly, without lingering, otherwise the unevenly frozen paraffin may not have time to seize throughout the filled volume, which will cause the candle to delaminate. A thick thread of natural materials (not synthetics) is pre-stretched, along which paraffin melted from the proximity of the flame rises along the fibers for complete combustion.As the candle burns out, the thread also shortens.

In the process of casting candles, paraffin should not leak in the wrong places.

After the candle has solidified, it must be removed from the mold.

After making sure that the first plug is fully functional and usable, pour out the next. The setting time of paraffin is from a few minutes, so it is recommended to have the same or different molded products on hand in order to quickly complete the process. You can remove the candle only after making sure that the mold has cooled at least to the temperature of the human body: heated candles can lead to burns due to the spilling of paraffin that has not cooled down in the depth of the volume of the poured product.

Having debugged all the casting steps, enterprising people start the production of handmade candles at home. Unlike factory stamping, they will showcase a look that you will not find in any store.