What is dublerin and how to work with it?

Dublerin is a popular material in the clothing industry. In the article we will tell you what it is, what its characteristics are, how it differs from non-woven fabric, how to choose and use it correctly.

What it is?

Dublerin is a cushioning adhesive material. It is made on a fabric basis and has one side with a special compound, by means of which it is attached to the main fabric. It is used to impart the required degree of rigidity to various parts, mainly of outerwear. This process is called duplicating parts before assembling them. It differs in the degree of elasticity and the type of base, it is thin, dense, with a different type of density of plain or other weave.

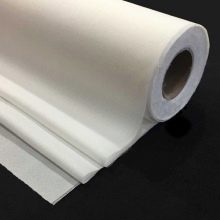

Visually, this is a canvas with a dotted glue layer in the form of tiny frozen drops of glue. It has different widths, it goes to production in rolls. Outwardly, it resembles cloth, canvas, knitted fabric or gauze.

Assumes fixation by temperature that activates the adhesive.

Application

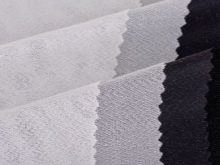

Parts are sealed with doublerin, due to which they keep their shape for a long time, and the products look neat. Thanks to this interlayer, the dimensions of the parts are preserved, shrinkage, stretching, and creasing are excluded. In this case, the properties of the base material do not change. It is better in wear, dry clean, wash. The dublerin itself is supplied to the domestic market in three colors: black, white, gray. It has a different degree of shrinkage, it depends on its structure. They duplicate coat, costume fabrics, jeans, leather, it is used for sewing corsetry.It is simple and convenient to use and has a long service life.

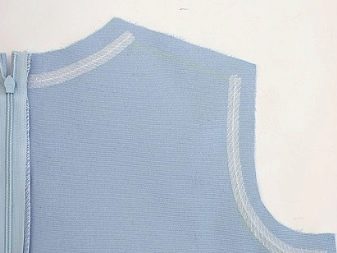

Breathable, hygroscopic, used mainly for duplicating dense and opaque materials. It is perfectly compatible with many fabrics of different compositions. In addition, it is used for parts of clothing subject to special stress (collars, lapels, pockets, armholes). Depending on the type of base material, it can be used in the production of curtains, lambrequins. Creates an excellent shape for backpacks, belts, cuffs. It can be used in the repair of outerwear, trousers, jeans.

It is sometimes used to glue the edges of heavily crumbling and loose fabrics. It is needed to strengthen the loops, fasteners, pocket valves.

What are they made of?

Initially, cotton was the raw material for the production of dublerin. Today, polyester and viscose fibers are added to the cushioning fabric. Due to this, the indicators of strength and wear resistance are improved.

When creating a material, a special composition is automatically distributed on one side. It can be polyamide, polyester, polyethylene. Spot application, fine, with equal steps. Depending on the woven backing, the location and size of the adhesive spots will vary. In heavy tissues, it is less common, and the droplets themselves are larger.

How is the material different from non-woven?

The difference between dublerin and non-woven is primarily in the base. In non-woven fabric, it is non-woven, made of fibrous or paper waste, fibers of secondary raw materials remaining after weaving. Dublerin, made on a fabric basis, has a weft and warp direction. Thanks to this, you can navigate in its cutting in order to correctly cut out a specific part.

Nonwoven fabric is better in this regard: it does not have a lobe section. You can cut it out without focusing on the share direction. Woven lining is more expensive, it is thicker than non-woven fabric. The differences lie in versatility. Dublerin is suitable for working with most of the known materials. Non-woven fabric has more limited capabilities in this regard. Dublerin is stronger than non-woven fabric, which tears and moves away from the material where it is glued when it is strongly stretched.

Along with this, the non-woven linen does not crumble at all at the edges, which is found in dublerin.

Views

Dublerin can be classified according to several criteria. By the type of base, it is inelastic and elastic. Each type of cushioning material is different. The fabric version is especially dense, it is designed to work with heavy textiles. It has found application in the manufacture of bags, shoes, hats. Gives strength to leather, fur, velveteen. Analogue for knitwear - a variety used in sewing shirts, blouses, skirts, clothes for children. This is an elastic type of dublerin, the thinnest of all.

Knitted look with pile - voluminous dublerin, not as hard as traditional, but denser than knitted. Stretchable along the weft, used in the sewing of jackets, jackets, blazers, suits, soft toys. Less often on sale there is also a chiffon type of doublerin, as well as a monoelastic. A highly specialized option - material for traditional or machine-type embroidery. These are heat and water soluble materials. Unlike other analogs, it has an auxiliary function that makes it easier to work when embroidering, at the end of which it is deleted.

Dublerin differs in the type of glued material. Based on this, several types are distinguished. For example, the knitted polyester or viscose version is designed specifically for stretch fabrics. It stretches a little, so it does not come off the main part during stretching.

The analogue for the skin differs in the manner of fixation. It involves a low-temperature method of melting the adhesive layer. This type is used in the production of shoes, bags, leather accessories. The coat variety is made from cotton and polyester fibers.This is the densest version of the dublenine, which gives a strong shape to the shelves of coat products.

By appointment, dublerin can be universal and specialized. The products of the first group duplicate any details, cutting it in shape. Variants of the second type are designed for specific items of clothing. For example, these include the collar type of cushioning material. It has a special texture, it is used to strengthen collars of various types (turn-down, stand-up, fancy).

Corset dublerin is made on the basis of coarse calico. Therefore, it is denser than cotton counterparts. It adheres reliably and is able to withstand increased daily loads.

Selection Tips

When choosing a doublerin, you need to pay attention to a number of factors. Not all varieties adhere equally well to any material. It is important to choose the right type of adhesive that will keep the garment in shape for as long as possible. A low-quality product has a weak hold. It can come off the fabric immediately after washing. At first, it’s hard to figure out how not to be wrong. Therefore, when choosing between different options, they rely on the planned product to be sewn.

For example, when sewing a lambrequin or curtains, a corset type is needed. For the dress-blouse assortment, take an elastic dublerin. For the manufacture of children's felt books - collar. The easiest way is to focus on a trusted manufacturer. Companies that value their reputation supply the market with products that do not flake off after washing. When buying, you need to focus on the type of work material. The denser and tougher the fabric, the denser the gasket is. For soft textiles, the knitted type is chosen.

For subtle matters, the thinnest doublerin is needed. If this rule is not followed, duplicated elements will spoil the appearance of the finished product. It is important to consider: too harsh does not mean good. Different dublerin has different shrinkage. Some species need decating. If you ignore this nuance, the glued thing may shrink in size, becoming wrinkled.

Often, when buying, you have to focus on the color of the product. This is especially true when sewing products from thin materials. If the working fabric is light, you need to buy a white dublerin. If it's dark and fairly dense, the color doesn't matter. You can buy both black, gray and white versions. If it has a loose texture, it is selected for an approximate color (dark to dark, light to light).

The nuances of working with fabric

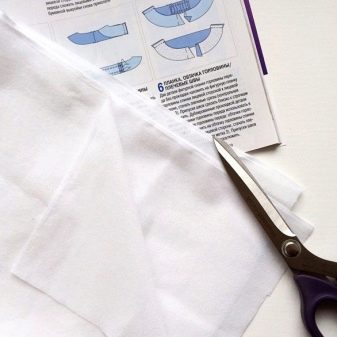

Duplicating product parts with an adhesive strip is an easy process. The basic rule of success is that the dublerin matches the underlying fabric to be stiffened. The main thing is to properly glue it with an iron on the prepared workpiece. In production, parts of the fabric and the dublenine are cut out separately. After that, duplication is performed on a special press. To do this, put the cut blanks from the fabric face down, place the cut parts from the dublerin on top with the glue down. Then close the lid of the press for a predetermined time.

After that, it is raised again, removing the details duplicated for sewing. If they are cut a little more than the woven blanks, they will stick to the work table. Therefore, they are cut strictly to size. You need to use dublerin at home differently. If you work with a very sliding or crumbling fabric, and you need to duplicate small details, it is easier to glue a part of the canvas and only then cut out blanks from it. To prevent the gasket from shrinking strongly, you can decorate it. To do this, it is soaked in water, then removed and laid on a flat surface and dried.

If you need to strengthen the shelves of a jacket, vest, collar, lapels, this is done according to the standard scheme. Parts are cut out from fabric and dublenine. After that, the dublerin is placed on the wrong side of the fabric with glue.Often, the technology requires cutting a spacer slightly smaller than the main blanks. This is necessary to reduce the thickness of the seams. Due to this, in industrial production, it is possible to do without a bum when turning collars, sides, valve edges. This simplifies further work with the fabric. Press slightly with a hot iron. Then moisten the pad and duplicate. Depending on the type of working fabric, select the "synthetic" or "wool" mode.

Be sure to glue it through an iron. This is to prevent the pad from sticking to the soleplate of the iron. It can also melt the fibers that make up the dublerin. The details of the gasket are cut out taking into account the shared thread. This minimizes the formation of wrinkles when hardening the parts of the working fabric.

An important point is the need to cool the hardened blanks. If they are removed from the tabletop while hot, they will stretch out at the points of tension and deform. They will have to be ironed again.

It is necessary to use dublerin not only correctly, but also carefully. There are often cases when the gasket is glued to the face or wrapped, gluing in the wrong place. For example, this happens when the front and back sides are confused. It can also happen if the master cut the dublerin with the wrong side to the glued fabric. When there is a need to remove it, the place of fixation is moistened with alcohol or lemon spray. To eliminate the defect, a small bottle of any product and an ordinary cotton swab are enough. The adhesive dissolves in both preparations, therefore it is removed from the surface of the base material. However, it must be removed without much friction.

Care rules

Dublerin is a material that does not require special care. However, in order for it to preserve the aesthetics of glued things as long as possible, a number of simple recommendations must be followed. The material withstands not only traditional ironing, but also steaming and high-temperature washing. Unlike non-woven fabric, it does not deteriorate during active and frequent washing. However, if it is stored for a long time, then adhesive particles may crumble from its surface. Most often this can occur in places of bends. Care depends on the type of material from which the dublerin is made. If it is based on synthetic fibers, they can lose their strength during vigorous washing.

To prevent this from happening, such products must be washed by hand or in a washing machine, choosing a delicate wash cycle at a temperature of no more than 30 degrees. After that, they are hung to dry without any wringing. Recommendations for washing products are indicated on the labeling, which manufacturers mark each unit of their products.

Do not wash products in which a corset lining was used to give the necessary rigidity.