What is hemp fabric and where is it used?

Hemp fabric belongs to natural types of textiles. From the material of the article you will find out where it came from, how it is produced, what are its properties, types, application, care.

Origin story

Hemp is a dioecious plant. According to archaeological data, it has been used for fabric production since ancient times (about 4000 years ago). It was used for sewing clothes of the common people.

For this, bushes with male flowers were selected. Strong fabric with high consumer qualities was obtained from them. Hemp fiber originally had a rough texture.

The first mentions of hemp textiles in our country appeared in the 17th century. It was used to make loose workwear. Its cultivation as a raw material for cloth weaving began during the reign of Peter I.

The first canvases were small in width. With the manual method of production, it was 40 cm, with the use of weaving equipment - 90 cm.

Sacks were sewn from harsh, unbleached fabric. Structures were caulked with hemp fibers. Such a canvas became the raw material for printing banknotes in the United States of America.

In 1853, the Levi Strauss & Co store opened with durable, wear-resistant hemp jeans.

However, mass production was made more difficult by the raw material production method and the hemp drug campaign.

Today, drug-free hemp is used in production. Thanks to modern technology, the production process has been simplified.

The material has become more accessible, clothes from it are often made to order in limited editions.The range of applications is wide, it includes a lot of products, up to thermal underwear.

Features of production

The production of hemp fabric is based on the spreading principle. After the leaves fall off, the stems are mowed and left on the ground, periodically turning. After they become lethargic and soft, they are harvested.

After the lobe, the pulp and fiber are separated. The fibers are dried, bleached and sent to the production of material. To do this, use the male type "poskon" with early maturation.

The prepared raw material is fed to the spinning and weaving equipment. Sometimes hemp yarns are combed and polished. This makes them softer and more elastic.

The production process of edge panels is carried out with minimal use of chemicals. Hemp is grown without the use of growth and maturation stimulants.

The output is dense ecological matter with a rough texture. The length of the thread is 0.8-4 cm. Primary fibers are used in spinning. The rest are used for tow. Male plants contain 25% fiber, female plants - about 15%.

Characteristics and properties

Hemp fabric has high air permeability. It is resistant to deformation, shedding, abrasion. Outwardly it resembles cotton or linen textiles.

Dust mites do not start in it, it is safe for human health. It is inert to the absorption of foreign odors and is resistant to dirt. Durable, can have knitted and plain weave threads.

Possesses increased creasing and shattering of the edge, low ability to drape. Its fibers are longer than cotton fibers. They are tactilely softer and warmer.

The fabric has a noble appearance and a porous structure, the canvas is perfectly dyed. The material practically does not shrink after washing at high temperatures.

Therefore, before sewing products, it does not need decating. The density of the fabric is 160-210 g / m2. It has an average water resistance, optimal vapor permeability, an average rate of moisture absorption.

The width of the panel can be 135, 150, 280 cm. The material does not accumulate static electricity, it has 2 front sides. The color is usually light bleached. The palette is small.

Textiles have medicinal properties and bactericidal effect. It removes perspiring odor, refreshes and tones the skin. It has a tonic, calming effect.

Hemp fabric is hypoallergenic and hygienic. It is temperature controlled, UV resistant, but expensive. The price for 1 running meter of unpainted fabric is on average 1600 rubles.

Plain dyed costs from 2300 rubles. The cost depends on the type of combined threads. For example, modifications with wool cost about 3200 rubles per 1 running meter.

Views

Hemp fabric can be classified according to different criteria. It can be classic and melange. The composition is completely hemp and combined.

In the second case, fibers of organic cotton, organic cotton, wool are woven into the fabric. In addition, there is also a tailored fleece.

According to the type of production, 2 groups of fabrics are distinguished: hemp is made from poske, and coarse textiles are made from mothers. Variants of the second type are used for the production of household materials. They have less fiber.

These are rough and rough technical type fabrics. They are particularly robust and capable of withstanding high mechanical loads. Inert to sea water.

Hump can vary in density of weave threads and colors. Thanks to the experiments of brands, the material can be very diverse.

Popular types are unbleached and unpainted canvases, analogues of a sandy natural and milky shade. Variants with cotton and jersey modifications, as well as denim, are no less in demand.

Manufacturers overview

Hemp textiles are produced by trade marks from Russia, China, Peru. It is easier to buy it online on specialized domestic sites.

- For example, it is available at the Fair of Craftsmen site, on the websites of Fabrics Land, Blagotkani, Fabrik Organik, Ecotkani LLC. Here it is presented in a wide range (regular, with enzyme softening, suit, twill, knitted, insulated).

- In addition, manufacturers offer options for furniture, dress-shirt type, analogs with a diagonal weave, varieties "herringbone", "canvas", "kulirny smooth surface".

- Produces good products Chinese manufacturer JHM. The company specializes in the production of materials of natural origin. These are fabrics with the addition of cotton.

- The list of suppliers of hemp fabric products includes LLC Alvitek, LLC Costera Fashion, LLC Knit Light.

Application

The range of uses for hemp fabric is varied.

clothing

Hemp fabric products are good for your health. They are indicated for mastitis, erysipelas, diathesis. Promote skin healing in case of abrasions, bruises, slow down the aging of the dermis.

The assortment is varied, it includes ethnic, light and outerwear. The first group of products includes dresses, sundresses, skirts, trousers, blouses, shirts, shorts, T-shirts, tops.

The second - jackets, jackets. In modern industry, it is a raw material for the manufacture of down jackets. It is also used for making socks, knee-highs, baby clothes, sports uniforms, underwear for newborns.

Household products

The material can become a raw material for decorative wall upholstery. Also popular models of bags and backpacks, moccasins, insoles, house slippers are sewn from it.

Harsh threads are used for household needs and interior decoration. These are fabrics by means of which the room is decorated, furniture.

In addition, this group includes fabrics for the production of sails, sacks, baskets, hats and carpets. The fibers are used for the production of car belts, decorative threads, and cords.

Fire hoses and cables are made of it, which do not change their qualities in a wet environment.

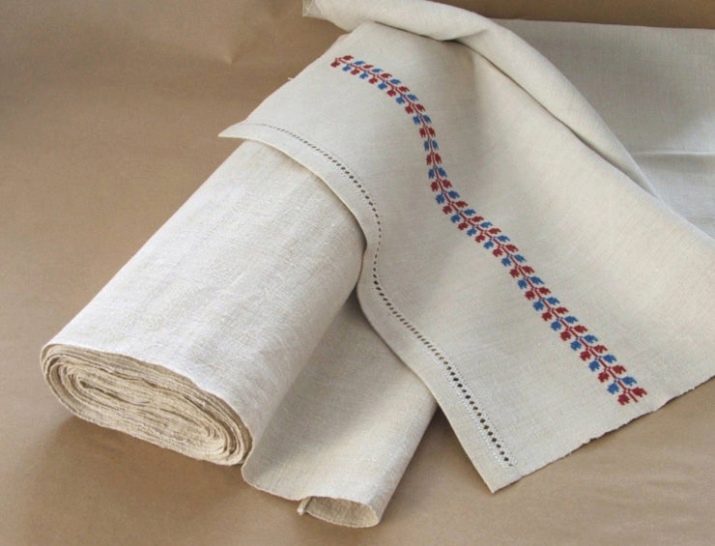

Home textiles

Hemp material has found use in the manufacture of various things for the home. These are a variety of curtains, curtains, drapes, napkins, traditional and festive tablecloths, kitchen towels.

In addition, bedding, pillowcases for sofa and bed pillows are sewn from it. It is used in the making of bedspreads, capes and canopies.

Heaters

The material is immune to mold fungi. Hemp cake is used in the creation of building materials. Sheet and roll insulation is used when laying soundproofing, laying roofs.

It has found application as insulation for laminate flooring, facade cladding of structures, in the production of biocomposite for car coatings.

Care Tips

Hemp fabric is easy to care for. In order for products from it to retain their original properties more, it is necessary to follow a few simple rules.

- You can wash products by hand or in the washing machine by choosing delicate washing mode with a temperature of 30-40 degrees... This will preserve the structure of the material and prevent deformation.

- Use appropriate detergents for washing... Liquid and powder materials are suitable. When choosing the type of product, it is worth considering foaming. It is less for detergents for machine washing. They are easier to rinse out of the material, so the garment will not be rough after drying. If the water pressure is low, an additional rinse is recommended after the main wash.

- Dry at low speed for 10 minutes. When choosing high, the material will be very crumpled. This will make it harder to iron your finished garments.

- Do not bleach hemp products in a chlorine-based solution. Do not dry clean them. To remove stains and other contaminants, it is enough to use laundry soap.

- You need to dry the washed things in a natural way. They dry quickly in the open air and do not need to be dried quickly. Do not place them on heaters or radiators.

- You need to iron things in the "linen" mode. Given the high crease of the fabric, when ironing, it is necessary to moisten the material with a spray gun or spraying from an iron. You can use the steaming option. It is especially relevant when the product is overdried and does not smooth out well.