Cordura: features and characteristics of the fabric

Everyone who is used to living actively and relaxing in nature is familiar with the name Cordura. It is a durable high-tech synthetic fabric. Certified Cordura nylon, with a half-century history, has earned many rave reviews for its properties. This led not only to great popularity, but also to the appearance of analogs and even fakes.

In order not to be disappointed in the quality of real fabric, you need to be able to distinguish it from fake.

What it is?

Cordura is a heavy, sturdy fabric invented by American scientists in 1935. Chemists at DuPont Textiles & Interiors have succeeded in creating a polyamide (nylon) fabric from threads with an extra strong structure.

First, nylon was created from water, ethyl alcohol, coal tar under the influence of temperature. Silk-like synthetics were named NYlon after the city of New York. Based on the new material, the developers have invented a more durable modification of synthetic fiber - Cordura. Its description differs from ordinary nylon in its structure technology (finely chopped and tightly twisted fibers). The thread with four times the strength has been patented by the manufacturer. Later, the Invista concern received a license for development. Today, this group owns all rights to the Cordura material.

The products of TM Cordura were originally intended for the uniforms of the soldiers of the American army. However, its properties were also appreciated in civilian life, having found successful application in many spheres of life.

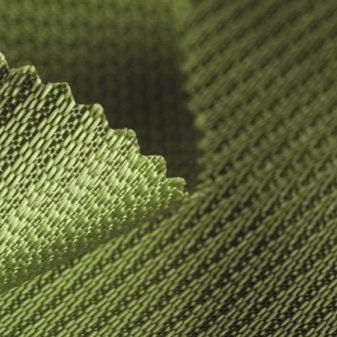

Thanks to its unique weave structure, Cordura is four times as strong as polyamide. Accordingly, the fabric made of it is more durable and resistant to wear. The melting point of Cordura is 210 degrees.This is a unique material containing 10% cotton fibers. It gives tactile softness to durable fabric, making it more pleasant to the touch. Cordura receives its water-repellent properties after treatment with a special impregnation in several stages. As a result, the wear-resistant short-pile fabric does not flake off during prolonged and active use.

In the process of fabric production, the fibers are tested for strength under strict control. Even the slightest deviations in the structure of the threads, which can negatively affect the quality of the finished fabric, are not allowed.

The material is made with various textures, including gloss and fleece. The range of colors is also not limited to camouflage shades.

Advantages and disadvantages

All invista cordura textures combine unique properties:

- in comparison with analogs, the level of tensile strength is 4 times exceeded;

- amazing wear resistance, withstands according to the Stoll test 7600 revolutions and more with sandpaper;

- non-flammable, melting point over 200 ° C;

- Water Resistant - Testing demonstrates immunity to wetting at 5000 mm H2O;

- excellent vapor and air permeability;

- long term of active operation.

An objective examination and assessment of the qualitative characteristics of the cordura matter draws the attention of consumers to a number of features that are interpreted as its disadvantages:

- demonstrates rigidity at low temperatures;

- makes noise when driving and mechanical operation in the cold;

- exposed to the negative effects of UV rays;

- dries for a long time after strong wetting (rare situations).

Types and their characteristics

In order to endow matter with new properties, others are added to its fibers during the production process. Thus, many derivative varieties of Cordura have been created. Available in non-colored fabric with various prints or in monochrome. The classification is represented by several types.

Cordura 1000-140-T 440 - is the classic primary source for all derivatives. The density of this modification is 1000d.

Plus 500-140-T 440 - less dense and heavy material compared to standard.

All other declared properties are similar to the original source.

Plus 330-122-T 440 - a type with a lower density for active use as a base for composite fabrics.

Plus Natural - created on the basis of a base material with the addition of a large amount of cotton fiber. Exceeds the strength of cotton fabric.

Tactilely more pleasant than the hard original, but inferior in many quality characteristics.

Plus ColorLock - demonstrates resistance to UF radiation and high color fastness.

Plus / Lycra - the modification is endowed with elastic properties, capable of stretching.

Plus / Taslan - a combination with insulation, designed for sewing garments for equipment in windy and cold conditions.

Cordura is available in a camouflage range of acupat and desert storm colors, and in solid colors: black, olive, green, gray, blue, light blue, yellow, red and coyote.

The certified fabric has no analogues, but there are fabrics that are maximally similar in quality and structure.

Kodra - Korean material that claims to be similar even in name. But the codra is significantly inferior to the original in strength.

Oxford (represented by types: RipStop, 900, 840, 600, 420) - fabric from the category of nylon, category synthetic. Plain weave enhances wear resistance. If treated with polyurethane impregnation during production, it demonstrates excellent water repellency in practice.

Oxford is thinner than natural Cordura. The surface is characterized by the absence of lint, smoothness and shine.

Maxsped - the most famous of the analogs of Cordura. Has an original polyurethane coating produced by DuPont.

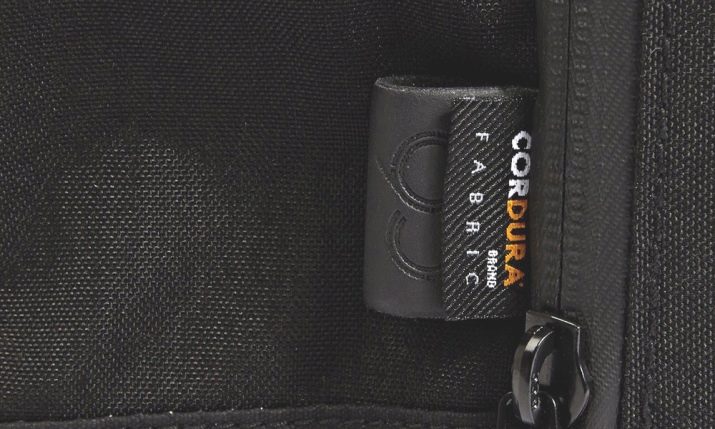

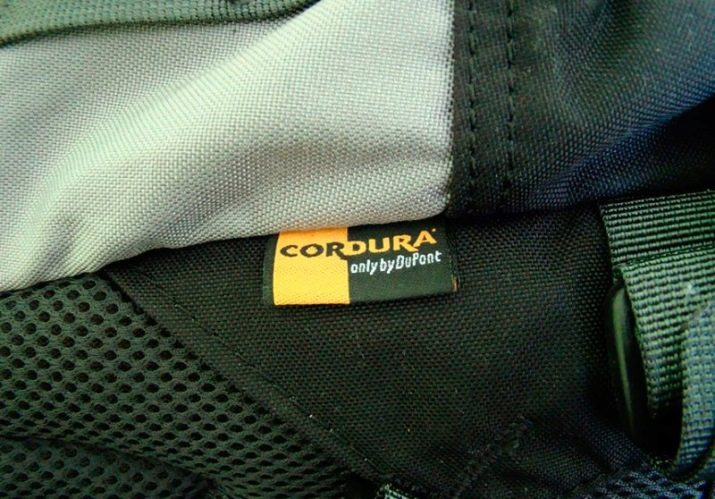

Due to its high cost and complex production technology, Cordura is only available in wholesale. In the application, the buyer must fill out certain points in the questionnaire, indicating his data, the desired color, footage, type of fabric and how many products are planned to be produced from the batch. This requirement is dictated by the fact that for each unit of the product a branded Cordura tag is allocated. In its absence, the products cannot be considered original. Knowing this, many clandestine shops produce fake labels for their non-original goods. Therefore, when buying, you need to exercise the utmost vigilance.

The original Cordura is identified by:

- gloss from the front side and matte roughness of the fabric from the inside;

- the polyamide coating layer on the surface is practically invisible.

The presence of a polyamide layer is clearly visible on a fake. This film will peel off under unfavorable operating conditions.

You can distinguish the original from a fake by comparing the front side and the wrong side.

Application

Initially, the fabric was used exclusively for sewing military ammunition. Excellent body armor, wearable backpacks, and protective shields are still sewn from Cordura. Later, Cordura became popular as a material from which clothing for sports and tourism is made.

The scope of application of Cordura today is unlimited. The fabric is used for the manufacture of products of any type that require certain properties with which it is endowed.

clothing

Types that are thinner and softer in structure are suitable for sewing.

Mainly:

- tourist and army ammunition;

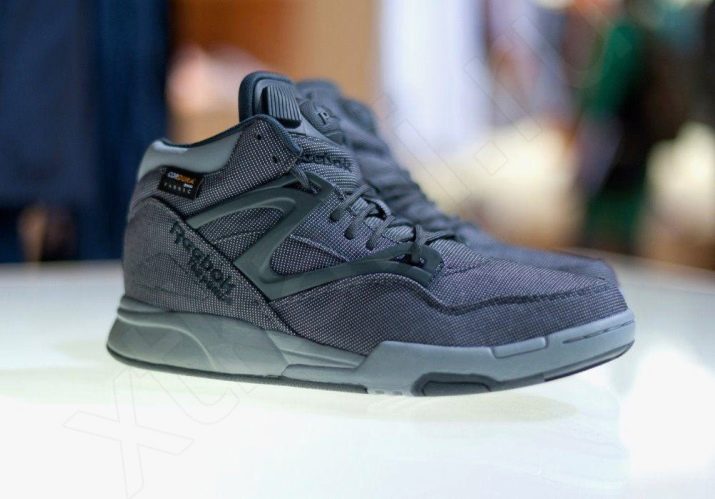

- parts of workwear requiring reinforcement - knee, elbow protection, upper work shoes;

- overalls, suits and jackets for long-term stay in conditions of variable weather, precipitation, mud and wind;

- most often the colors have a camouflage pattern, but can be plain dyed in any color.

Equipment

Strong and durable material is very suitable for the production of wear-resistant travel bags, belts, belt bags for tools, sports and hiking backpacks, covers, tents for various purposes.

Cordura is ideal for applications where high strength and identical wear resistance are important. But for hunting and for long hikes, especially in the mountains, it is better to choose lighter equipment.

Cordura makes noise on the move and is noticeably heavy for extended wear.

Furniture

The original American fabric has the most suitable properties for sewing furniture or tents such as the bottom. Parts in contact with the ground require increased strength and endurance. They also make some parts from strong synthetics for folding chairs and stools, which they take with them on hikes, outdoor recreation and on picnics.

Care

When heavily soiled, clothes made from Cordura are wiped in places where dirt accumulates and washed in an automatic washing machine. Drying of such products takes quite a long time, and it is not allowed to dry in direct sunlight.

The fabric usually does not need ironing, but if necessary, the fabric can withstand ironing at t up to 200 degrees. Iron only from the front side.

Since products made of certified synthetics do not actually wrinkle, they can be stored folded in any order.

Given the fact that dense fabric is quite voluminous even in a compact addition, you need to find a place for it in your wardrobe.

Cordura travel bags are in great demand and have served for decades. No care is required. Unless periodically cleaning from dust with a clean, damp cloth. For all its good quality, the material is very unpretentious and durable.

If you buy things made of such synthetics, they will definitely come in handy on the farm and will please you with their durability more than once. Especially on long distance hikes. It is better to dry a wet Cordura tent flat. Stretched thick fabric dries faster outdoors. It is unacceptable to send wet things for storage due to the high probability of mold.

Shoes with Cordura inserts or completely sewn from durable synthetics can be machine washed. Drying is carried out in a standard way for shoes with a cloth top: stuff soft paper (newspaper, packing cuts) tightly inside. You cannot dry in the sun in the same way as near heating appliances.

Cordura products are worth the money you have to pay for them. They are incomparable with their counterparts in terms of their wear resistance. Such awnings are safer, tents are warmer, bags are more convenient, backpacks are more ergonomic. These characteristics are enough to avoid acquiring more affordable and less durable counterparts in the future.

See the next video for a comparison of Cordura with Oxford.