Overview of technical fabrics

Technical fabrics are materials with a specific function and purpose. In the article we will tell you what they are, what they are, who releases them.

What it is?

Technical fabrics - textiles used in everyday life and industry for different purposes. They have special characteristics and often have a rough texture. They differ in the method of production and composition.

Classification

Technical materials can be classified according to different criteria.

By appointment

Based on the scope of use, materials are filtration, wiping, textile.

The filter material is used as a filter for various liquids. It can be woven, non-woven, has different density, can be used in several folds to adjust the level of filtration.

Cleaning cloth - rags for cleaning floors, dusting, cleaning household items.

It absorbs moisture well and can be used for wiping machine parts.

Textile modifications - options for the production of special clothing, capes, covers, protective curtains. In addition, their purpose is to protect against moisture and pollution.

There are a lot of groups, into which the main types are divided.

-

Industrial (filtering, cleaning, isolating).

-

Transport (for airbags, belts, car tires).

-

Geotechnical (separating membrane fabrics).

-

Agrotechnical (covering and heat-insulating materials).

-

Protective (modifications of fire, hydro, wind protection).

-

Packaging (containers for packaging various materials).

-

Medical (for wet wipes, lining materials).

-

Household (covering, for pools).

-

Eco-friendly (for water and dirty air purification).

By composition

The composition of the fibers used is natural, artificial, blended. Variants of the first type are made from flax, cotton, and other fibers. In the production of artificial polymers, polyester fibers are used.

Jute and linen (for sackcloths, tarpaulins), metal wire are also used for manufacturing. The composition is related to the purpose of use and is regulated by GOST standards.

The raw materials for the manufacture are rocks, quartz glass, viscose, lavsan threads. In addition, synthetic threads are used in production.

By production method

Fabrics for technical purposes include materials obtained by textile, non-woven, film, combined production. The type of thread is single-component and combined.

With the textile method of production, fabrics are created on weaving machines. Nonwovens are compressed to obtain the desired shape and density.

They are made from granules or powder, which is melted and shaped by passing through filters to form filaments. Films are created on specialized equipment.

Top best views

There are many varieties of technical fabrics. We offer a brief description of the main types, their differences and properties.

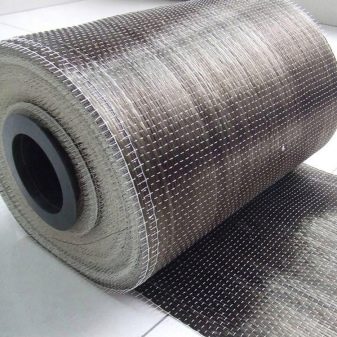

Polyester

Synthetic polymer textiles with a dense, soft texture. Hygroscopic, poorly breathable. It happens one- and two-sided. The structure of the fibers is combined, consisting of areas with and without crystallization.

Possesses oil-, dirt- and water-repellent properties. Hypoallergenic, inert to alkaline substances, acids. Peels and builds up static charge.

Propylene

Propylene Textile - Double Faced Carbonated Oil Material, which goes through a complex process until the granules are remelted and the threads are cut.

Perfectly evaporates moisture, is inert to corrosion. Resistant to tearing, cutting and can stick together when heated.

Electrifies on use, resistant to degradation.

Aramid

Polymer fabric has a simple plain, twill, satin weave of threads. It can be one- and two-sided, with a smooth surface texture. Dense and dimensionally stable.

It is a strong and durable technical fabric. It is lightweight, resistant to fire, pollution and mechanical stress. It is multifunctional, does not pierce well, does not break, does not form holds.

Basalt

This textile is made from rock. The cloth of twisted basalt threads has a plain, twill, satin weave. It is non-toxic and environmentally friendly.

It has low thermal conductivity, melting at high temperatures. Resistant to alkali, inert to mold and rot. Does not decompose, it is used in aircraft construction.

It is used as a reinforcing textile where strength is needed while maintaining lightness.

Pvc

PVC textiles are optimally rigid, with a polyester backing and a PVC plastic sheath. It has 2 front sides, glossy texture, different color (white, black, blue, red).

Used for banners, awnings, bags, thermal protection, tents, industrial canopies. It is waterproof, resistant to aggressive substances. Wear-resistant and lightfast, electrifying and non-degradable.

Kevlar

Kevlar can be single-sided and double-sided, it has a plain weave of threads. Differs in high-strength texture, resistance to deformation and stretching.

The fabric is supplied to the market in dyed form (black, red, orange, brown). Has a smooth texture with a plain weave of threads.

Nomex

Double-faced material, especially hygroscopic. Resistant to melting and burning, tearing. Does not wear out during friction, has moderate electrification.

Non-toxic when heated, has a high water resistance. Deprived of antistatic properties, treated with Teflon impregnations. It is a heat-resistant acoustic material.

Spunbond

Non-woven double-sided synthetic fiber textile with a square or diamond-shaped fine pattern. Particularly durable and practical, it allows air, water and light to pass through.

It is used as a covering and insulating material in various technical fields. Lightweight, accessible, fireproof, resistant to any weather conditions. Antibacterial.

Panacea

Thick, fine fabric with plain weave. Possesses optimal hygroscopicity, low air permeability. Moderately vapor permeable.

Double-sided, hypoallergenic, permanently colored. Resistant to chlorine, dirt, peeling, sun fading. Low shrinkage.

Tisi

Soft dense combined fabric with plain or twill weaving of fibers and monochromatic dyeing. Double-sided, durable, lightweight, dimensionally stable.

Does not fade from UV rays, is inert to mechanical stress, durable, easy to clean, dustproof. Inelastic and wear-resistant, has high thermal conductivity.

Sackcloth

Textiles with a rough texture, plain weaving of threads, low water resistance. Possesses low electrification, average air permeability.

Non-staining, strong, durable, wear-resistant. Multifunctional, environmentally friendly, natural. Unpretentious in care, affordable. Created from threads of flax, jute, hemp.

Canvas

Rough dense fabric with smooth weaving of threads. Double-sided, waterproof, fire and light resistant. Refers to materials of a natural type.

Windproof, inert to mechanical stress. Does not rustle in use, has a low cost. Vulnerable to cold temperatures.

Tarpaulin

Long-lasting woven fabric with a coarse, dense texture, 2-sided. Waterproof, fireproof. It has windproof properties, durability, and practicality.

Budget, eco-friendly, breathable. At the same time, it is heavy and tough. It is used for the production of tents, awnings, raincoats, bags, workwear.

Kirza

Simple, practical, tough natural fabric with low hygroscopicity and low moisture absorption rate. Has low air permeability and vapor permeability.

Resistant to punctures, tears, abrasion. It is characterized by low production costs and almost no accumulation of static electricity. Cracks at critical temperatures.

Popular manufacturers

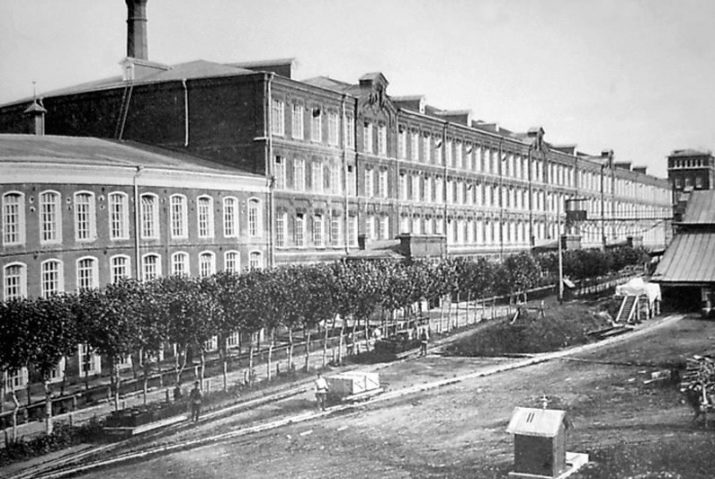

Several companies are engaged in the production of technical fabrics in Russia. The list includes such factories as:

-

"Soyuztextile" (manufacturer of filtering, covering materials);

-

spinning and weaving mill "Zalesye" (supplier of filter fabrics);

-

LLC "Triumph Capital" (production of tarpaulin, double-thread);

-

JSC "Tekskor" (technical raw materials based on polyester threads)

-

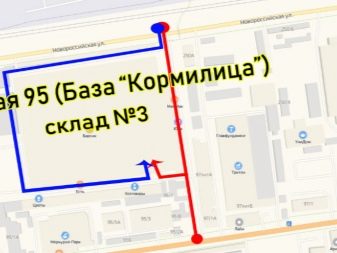

LLC "Kirillitsa 23" (supplier of fabrics for industrial use);

-

LLC "Premier Textile" (technical fabrics for workwear, awnings, bags);

- "Industrial textiles" (household materials).