All about printing on fabrics

Printing on fabric is a highly demanded and multivariate position today. Virtually any print can be made on any textile. And this is interesting both for those who open a small business, and for those whose production appetites are great. And also it may be interesting for experimenters, because some types of printing are possible even at home.

Views

The most interesting and effective types are worth considering in more detail.

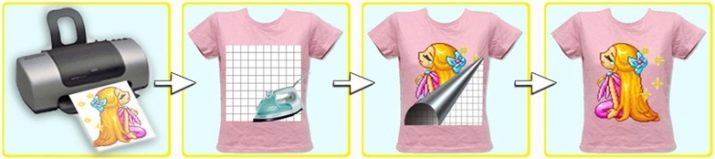

Thermal transfer

This is the name of the method of transferring an image to a surface associated with short-term temperature exposure, namely, a temperature of 120 to 190 degrees. And also the technology provides for the presence of an intermediate carrier. He and the surface of the product briefly come into contact, heat up. The main advantages of this technology: instant transfer, preservation of the full color palette, the ability to print single copies (that is, not mass production), and finally, getting a wash-resistant image.

What else is important to know about thermal transfer:

- any color printers can be used;

- durability depends on the quality of the paper, and also on the properties of the paint;

- the best will be the image applied by devices that work with solid dyes (they are not afraid of water or heat);

- intermediate media is a transfer paper covered with the finest film, which is transferred to the fabric along with the image itself;

- if you need to print on a light surface, use paper with a transparent layer of plastic, if for a dark and colored one - with white opaque;

- thermal transfer presses are very different - manual and semi-automatic, large and compact;

- if you need to seal two sides, the bottom plate of the press is laid out with a teflon sheet so that the drawing on the back does not stick.

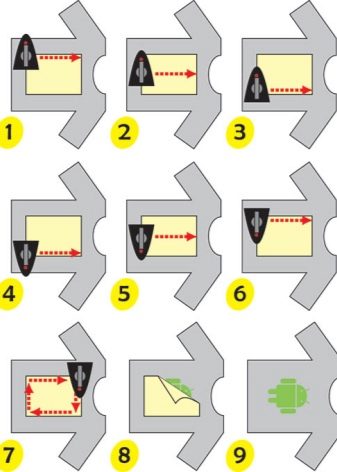

Thermal transfer in everyday life, by the way, is also real. Only it will not be a large-sized technique, but an ordinary iron, which will be a heat press. True, it’s not that easy. Even the transfer time will increase, and if the pressure is not enough, rejects cannot be avoided. The productivity of the iron is, of course, low, and special papers cannot be used in any way. And washing fabrics with such an image is difficult. But with small images, there shouldn't be any problems.

In general, thermal transfer technology is suitable for small, modest printing houses, for design studios and advertising agencies, print shops. And it provides for only small editions.

And so that the image is also read normally, it is printed in a mirror image.

Thermal transfer can be terminated by hot or cold separation. Hot means the separation of special paper immediately after heating, the paint will still be hot. Some of it will remain on the fabric, some on the transfer paper. The saturation of colors on a dark surface is not always 100%. But the paint layer is soft to the touch.

Cold peel means that the paper does not release from the substrate until it has cooled down completely. The entire dye goes to the textile base. The image itself will turn out to be glossy, rather dense and harsh. This distinguishes it from soft hot separation. But this method prints more easily on dark surfaces.

Silkscreen

Another name for the method is screen printing. The motive is transferred to the fabric by special nets, through their base the dye composition enters the textile. This printing is distinguished by a rather expensive preparation, because each type of ink requires its own stencil. Silk-screen printing allows you to interact with different fabrics: natural, synthetic, artificial, blended. Light and dark fabrics require different types of colors, that is, the tones applied to the fabric are quite varied. Monochromatic and bright multi-colored - silk-screen printing equally successfully transfers any image to the base.

This method is almost always associated with large-sized machines, and therefore the batch of printed products can also be large. The larger the circulation, the cheaper it is for the customer. But preparation is a moment that can confuse those choosing a fabric printer. Indeed, you need to customize the forms, prepare the machine itself, and so on. But the printing speed will be advantageously high, and the cost of transferring the picture will be relatively cheap. Finally, the main thing is that the quality of the print is high, and the product with the transferred pattern is not afraid of washing and wear.

Screen printing machines can be:

- crucible - the printed and form surfaces are flat;

- flat-printing - their printing surface is flat, the supporting surface is in the form of a cylinder;

- rotary - cylindrical here are both main parts, and these machines work with rolled materials.

There are single-color machines, that is, they have one printing section, there are two-color machines - and this is already a whole carousel installation. Silk screen printing also requires a drying structure.

The print is dried after each coloring composition is applied, because they should lie flat, excluding any mixing.

Silkscreen inks need dense and opaque. It can be a triad set, or it can be a ready-made color set. There are voluminous complex paints, there are those with a metallic sheen, fluorescent, ultraviolet and others. And for this type of printing on fabrics, a squeegee blade is required. Without a squeegee, you won't be able to push the paint through the mesh. Printing on light fabrics with this type of ink transfer is not a problem, but with dark fabrics it is not so simple.

First, you will have to apply a light substrate, which is then printed with process inks. Or, you can first apply light colors, and then those that are darker (that is, light ones will become the background for dark ones). Usually etching dyes are used. The main advantage of this printing is low cost price for large runs, wear resistance of finished fabrics and excellent printing speeds. But the main disadvantage is serious prepress, considerable costs for the technique itself and the difficulty of printing in dark.

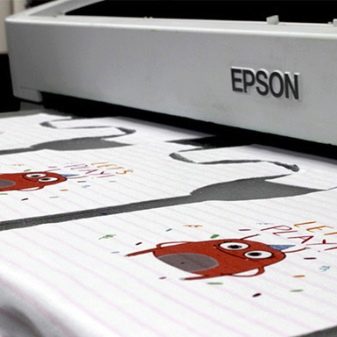

Digital

It is a method of printing from a specific digital medium. And the quality of the picture depends precisely on the properties of the printer, which will transfer it to the fabric. For quality printing, digital prints must be flawless. The picture is applied using an inkjet method, and then it still needs to be dried. The paint is better applied to white and light-colored fabrics. Well, if the textiles are very dark, you may have to make a light backing first.

The main advantage of such printing is fast pre-production preparation and printing with the highest resolution. And the pictures can be changed quickly, without much effort. Still, digital printing cannot be considered cheap. And the full cycle, if you really calculate it, will take from 5 to 15 minutes per item. For a small batch, for example, T-shirts, it is quite an option.

The size of the printer also limits the size of the transferred image, of course.

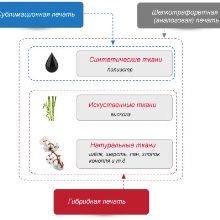

Sublimation

And there is also a sublimation version of digital printing, in which dispersed dyes are expected to be applied to a polyester medium. And the drawing (or photograph) will be fixed by heating the carrier in special tunnel ovens, steam steamers or thermopresses. This method is more often used for transferring images to synthetic fabrics. For example, sportswear. The pattern will sit tightly on the fabric, but at the same time it will not be felt by touch.

And it is not scary to wash it, and it is not afraid of wear and tear, and it is not afraid of ultraviolet burnout, as well as friction. The brightness of the image with the sublimation method withstands competitive comparison with the above methods. But the sublimation method is suitable only for prints on light fabrics, and even in the process of manufacturing the same clothes. To put something on the finished drawing, on top of it simply will not work. That is, when purchasing such a thing, you need to understand that sublimation printing has already been invested in its cost.

Tips for choosing a technique

In short, how to choose the best type of printing, we can say so. Pictures that are applied using silkscreen printing are considered almost eternal. Yes, it will be expensive, but the abrasion of the print is minimal. What can not be said about the print, which was created using thermal transfers - it is less stable. But silk-screening will pay off if a large circulation is required. Thermal transfer does not depend in the price issue on the circulation, that one T-shirt, that 20 will be printed, most likely at the same price.

Sublimation printing is more often used on synthetic fabrics (but there are many restrictions, you can't print much on black T-shirts). And there is also direct printing on textiles, which dispenses with intermediate carriers - on any natural light fabric, the print will be successful, with high detail and photographic quality.

How to translate a drawing at home?

Iron-on transfer is a way to make printing on fabric right at home. And you can print a drawing with the same conventional printer, which was previously used only for paper. That is, the main equipment in this business will be a computer and a printer. And you will also need scotch tape (you can replace it with mounting tape), thick paper, scissors, cloth. If it is cotton, the chances of success are greater. Because transferring the drawing to denim, for example, fabric is unlikely to work.

This is how the process looks like.

- Put a piece of fabric on a sheet of paper, carefully glue it around the edges with tape or mounting tape.

- We need to make sure that everything is fine, not crooked. Only then the sheet is inserted into the printer, and you can press "print".There will be no reactive result, but in general the print speed should not be too different from the usual one.

- As soon as the sheet with the print has come out, you cannot immediately touch it.

- Then an iron is taken and the finished work is ironed through a thin sheet of paper. You need to iron it for at least 30 seconds. This will dry the ink faster and adhere better to the surface.

If you do without an iron, the picture will dry for at least half a day. And only after that, the fabric is very carefully removed from the sheet.

Or you can simply cut the sheet around the perimeter. A simple method worth taking on a pencil. You can change the fabric, decorate it not only with painstaking embroidery, but also with printing. And she, in turn, offers more than one affordable and high-quality option.