Everything you need to know about rubberized fabrics

Rubberized fabric is a common material in various areas of production, whether it be clothing or technology. Today on the market you can find products of different densities. We would like to draw your attention to detailed information about the main properties of the fabric, its varieties, and areas of application. We will also give recommendations for making at home.

Basic properties

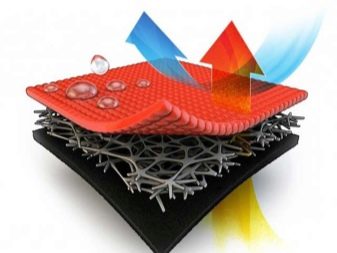

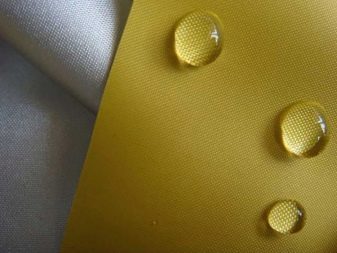

The rubberized fabric is characterized by mechanical stability. The base is made of plastic textile that can withstand high loads, therefore the tensile strength is high. Artificial fibers are used as a basis. Of course, the main advantage of this material is moisture resistance. The rubber layer will not allow water to penetrate inside, moreover, it is elastic and withstands stretching, which ensures a long service life.

As for the influence of an aggressive environment, the fabric is able to remain intact even in such conditions, therefore it is often used for the manufacture of overalls. In manufacturing plants, rubber is mixed with pigments of different colors to make workwear for different purposes.

A big plus is that the material will not rot, will not succumb to the influence of chemicals. He is not afraid of direct sunlight and microorganisms.

Such characteristics are due to the composition of the base and the method of applying the rubber layer, which has been used for many years. Rubber does not allow gas and even small particles of steam to pass through, which is important.Any product made from it will be protected from moisture, bacteria and mold, it is heat-resistant and remains presentable for a long time. On the downside, the fabric is not breathable. You can also pierce the material with a sharp object, so be careful.

Features of production

At the first stage, a base is selected, which can be either synthetic or natural: it depends on the manufacturer. Often these are wool, viscose, cotton, linen, nylon or nylon. Further, the material is covered with a mixture of rubber with gasoline, and when the vapors of the latter evaporate, a rubberized layer remains outside. In this way, the product becomes durable, elastic and water-repellent.

So that during operation at low temperatures the product does not crack, and at high temperatures does not creep, vulcanization is carried out at the final stage. We are talking about the effect of hot steam with sulfur on rubber molecules, which change their structure, turning into a single network.

Types and their application

There are several types of rubberized fabric on the market that are used in different industries and have certain characteristics. The classification is determined by the production technology and operational properties. The single-layer material is covered with rubber on one side only, and the two-layer material is covered on both sides.

You can also find multi-layer fabrics that are made up of textiles, felt and rubber.

Technical rubberized material is used in the manufacture of various products. Balloon fabrics have a silk base, which has a spray of 15 layers of the composition, which creates the effect of gas permeability. This is necessary for balloons and air devices. Thanks to calendering, the material is used to create containers in which water or hot liquids are stored. Such raw materials are dense and strong, therefore they are perfect for sewing equipment, medical uniforms, equipment of orange and other colors. Also, the rubberized fabric is ideal as a base material for backpacks, tents, floats and lifeguard vests.

If we are talking about fabrics based on nylon or silk, then clothes for employees of the oil and gas industry are sewn from it. Such uniforms protect a person from moisture, steam and the influence of an aggressive environment. Mattress covers and bedding for couches in hospitals are also sewn from it. The fabric marked 23M is made of nylon and rubberized not only on both sides, but even between the layers. Often the material is used in the manufacture of covers and as a shelter. In enterprises where work involves welding and the use of hazardous equipment, personnel must wear special protective clothing and footwear to avoid injury and accidents. It is here that this material cannot be dispensed with, which prevents injury and covers open areas of the body.

It should be noted that The fabric is also used in the construction industry: it can be used to make pipelines, it is coated with concrete, ceramics and wooden surfaces to provide antiseptic properties. In mechanical engineering, the rubber material is useful in the manufacture of shock absorbers, inserts, or anti-vibration pads. As mentioned above, the food industry actively uses this product to create containers and containers, containers for storing or transporting food and liquids.

Care Tips

To extend the life of any product made of rubberized fabric, it is necessary to take into account the recommendations of specialists, as well as to properly care for it. When it comes to equipment and workwear, it is important to avoid contact with cutting objects, since a puncture will worsen all characteristics. Such mechanical damage can no longer be sewn up, however, the product can be saved with the help of professionals who know how to repair it.

As for contaminants, they can be easily removed with ordinary soapy water and water.

With long-term storage, any thing made of such material can become more rigid. To change this, you need an aqueous solution with the addition of ammonia. During cleaning, do not use gasoline or other aggressive substances that will only spoil the performance. Rubber products can crack at low temperatures, so it is important to avoid these conditions. If you follow all the recommendations, the rubberized material will serve for a long time and faithfully. This is a multifunctional product that is universal in different industries, which is one of its main advantages.

Rubberizing at home

Many people wonder if it is possible to make such a fabric with their own hands without professional equipment. The answer is yes. To do this, it is enough to find a suitable impregnation and follow the instructions. It is recommended to use products from leading manufacturers, so the item will not be damaged.

There are several options on the market, here are the characteristics of some of them.

- Impregnation WR is in the greatest demand, it can only be applied on the outside of the product, after which the drops of water will roll off and will not remain on the clothes. The big advantage is that the protective layer will prevent fungus from spreading, let alone liquid molecules due to fog or vapor.

- PU is a polyurethane impregnation, which is used to process the inside of products, whether they are clothes or shoes. Even if it is wet outside, moisture will not get inside, which is important. At the same time, temperatures below -25 degrees Celsius will negatively affect the integrity of the material, which will begin to crack, which must be taken into account immediately.

- Next on the list is DuPont, which in terms of characteristics resembles the first in the description. It is applied externally and is suitable for harsh conditions. Such a substance is used in the production of upholstery, in the sewing of jackets and tents. The impregnation is popular in the Far North region, where there are industrial enterprises.

- For the interior, consider PD, which will make any fabric much stronger, and not only moisture resistant. Some professionals prefer to mix this impregnation with others. This is the most budgetary composition, while its quality is at the highest level.

If you want to add color, you can add a special pigment, having previously studied its compatibility with the impregnation.

A workshop on making rubberized fabric can be found in the following video.